TM 55-203

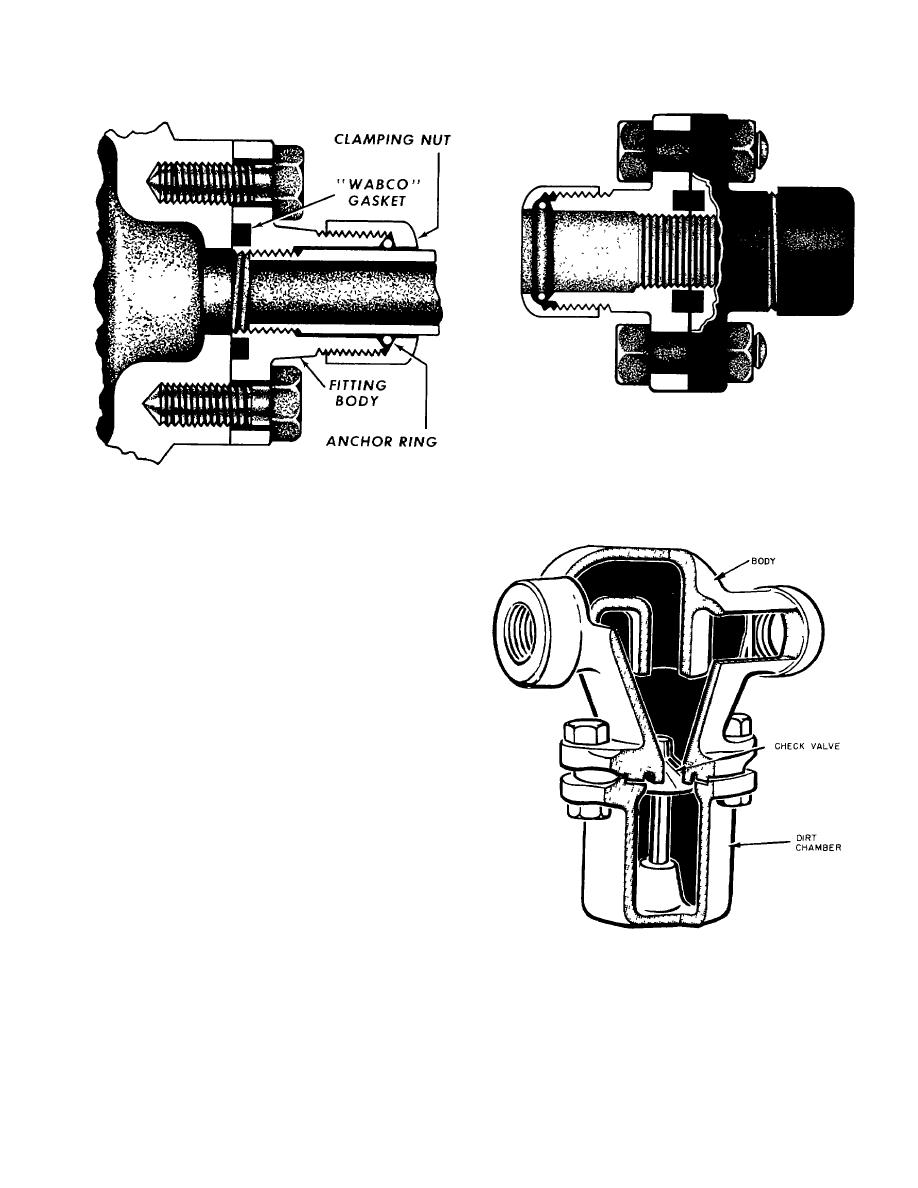

Figure 8-36. Wabcotite pipe union.

Figure 8-35. Wabcottie fitting as used on the brake

cylinder and reservoir.

of this fourth or slow direct exhaust position avoids the

necessity for resetting a retaining valve en route, especially

on adverse grades. This new design of pressure retaining

valve has many constructional features which are

considered improvements over the former types. The

valve is mounted upon a pipe bracket which is fastened

permanently upon the car and to which the pipe connection

is made. This arrangement makes it possible to remove

the valve for cleaning and repairs without interfering with

the piping. A strainer, similar in construction to the AB

valve brake pipe strainer, is located in the bracket for

cleaning the air before it passes to the valves and chokes

within the retainer. A wasp excluder, similar to the

separate unit now being furnished with the standard

retaining valve is built into the retainer body casting. It

consists of a flexible rubber diaphragm confined within a

bell-shaped housing. A Wabcotite fitting connects the

retainer pipe to the retainer pipe bracket. This insures

against breakage of the pipe at this point. Provision is

made for attaching the device for testing the brake

cylinder, retainer pipe, and retainer without removal from

the car.

(2) Exhaust positions. The exhaust of brake

cylinder air through the release control retainer in the four-

Figure 8-37. Centrifugal dirt collector.

handle positions is as follows:

(b) In high pressure position, handle 5 is turned to the

position marked HP, 45 degrees below horizontal. The

(a) In direct position, handle 5 is turned downward to

triple valve exhaust is through strainer 25, chamber A, past

the position marked EX. The triple valve exhaust is

low pressure valve 4, through intermediate choke b, past

through strainer 25, chamber A, unrestricted passage g,

high pressure 4a, through final choke t, passage s, drilled

and past wasp excluder 22 to atmosphere in unrestricted

port x in cock key 6, and past wasp excluder 22 to

normal manner.

atmosphere. The pressure retaining valve of each valve is

10 pounds, and since the

8-43

Previous Page

Previous Page