TM 55-203

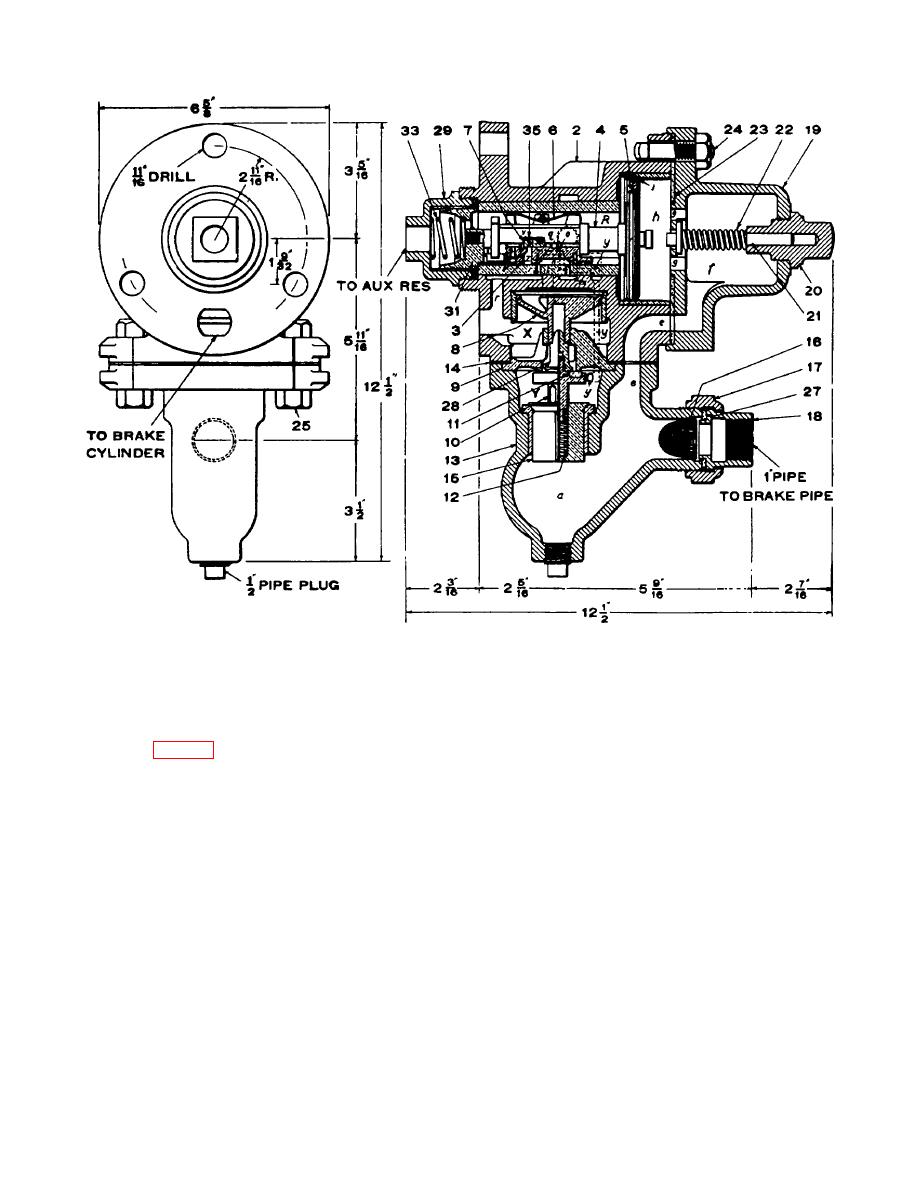

Figure 8-32. K-2 triple valve, actual section and end view

strains are removed from its weakest point and

permits longer time between cleaning periods (may be

concentrated at its strongest point. The gasket is under

the same as for triple valve and brake cylinder).

an initial strain, but it is not subject to any subsequent

movement because the union flange is drawn up solid,

(2) Check valve. The purpose of the check

metal to metal (fig 8-36).

valve is to hold in the dirt chamber the collected dirt

under all conditions of airbrake operation. The body

e. Centrifugal Dirt Collector

portion has a machined seat against which the check

valve seats when a heavy reduction in pressure occurs

above it, such as that during an emergency application,

(1) Location. The centrifugal dirt collector is

thereby shutting off communication between the dirt

located in the branch pipe in order to protect the triple

chamber and the dirt collector outlet. The check valve

valve against the entrance of pipe scale, sand, cinders,

is so designed and placed on the valve stem as to

dirt, or foreign substances of any kind. Figure 837 is a

permit a rocking motion whereby any fine dust which

sectional view of the standard "Check Valve Type" in

may collect on top of the check valve will be shaken off

which the detachable enlarged dirt chamber and the

into the dirt chamber.

check valve are the outstanding features. This design

comprises two separate portions; the upper or body

f. Pressure Retaining Valve

portion to which the pipe connections are made, and the

lower or dirt chamber portion which contains the brass

umbrella-shaped check valve. The two portions are

(1) Description. The following description of

bolted together and the joint between is protected by

the pressure retaining valve applies in detail

means of a rubber gasket. The detachable dirt chamber

provides for easier cleaning, and the increased capacity

8-40

Previous Page

Previous Page