TM 55-203

to the AAR standard. Many older types are in service

which differ in detail, but the principle of operation is the

same and that portion of the text covering operations,

therefore, applies to the older as well as the newer types.

(2) Standard retaining valve.

The standard

retaining valve for freight equipment cars is a three-

position, 10to 20-pound duplex spring type retaining valve

having nominal blowdown valve of 50 seconds in the 10-

pound position and 90 seconds in the 20-pound position. A

wasp excluder fitting (g below) is provided in the exhaust

opening to prevent the plugging of the exhaust by the

entrance and nesting of mud wasps and other insects A

fixed choke orifice (choke k) is incorporated in the passage

(port g) between the high and low pressure cavities, and

the springs and valves are permanently enclosed in the

capnuts, thereby preventing possibility of spring distortion

and assuring permanent closing valves. Both chokes k

and h are drilled brass plugs and the choke ports are coned

on the pressure side to prevent dirt from accumulating and

closing the port.

(3) Adjusting the retaining valve. This valve is

connected to the triple valve exhaust as illustrated in figure

cylinder to exhaust freely to the atmosphere, or (b) to retain

a portion of the air in the brake cylinder when making a

release, in order to hold the brake applied while recharging

the system. The retaining valve is usually fastened to the

end of the car, near the brake staff, by lag screws or bolts.

(4) Lock key. The cock key, figure 8-38, has

three outlets: one to the atmosphere through the pipe tap

EXHAUST, one to the low pressure side of the retaining

valve proper and another to the high pressure side. The

valve portion consists of two valves 4 and 5 normally held

to their seats by their springs 20 and 21 and holding ports d

and e closed. When the handle of the retaining valve is

turned down, passage a in the cock key connects chamber

D and the outlet c to the atmosphere. When the handle is

turned up to the horizontal position, passage a connects

chamber D below the cock key with port e, so that when a

release is made the air exhausting from the brake cylinder

flows to the retaining valve and through passage a and

passage e to the face of the valve 5 which it must lift

against the pressure of spring 21 in order to flow to the

atmosphere through the small vent port h in the low

pressure capnut.

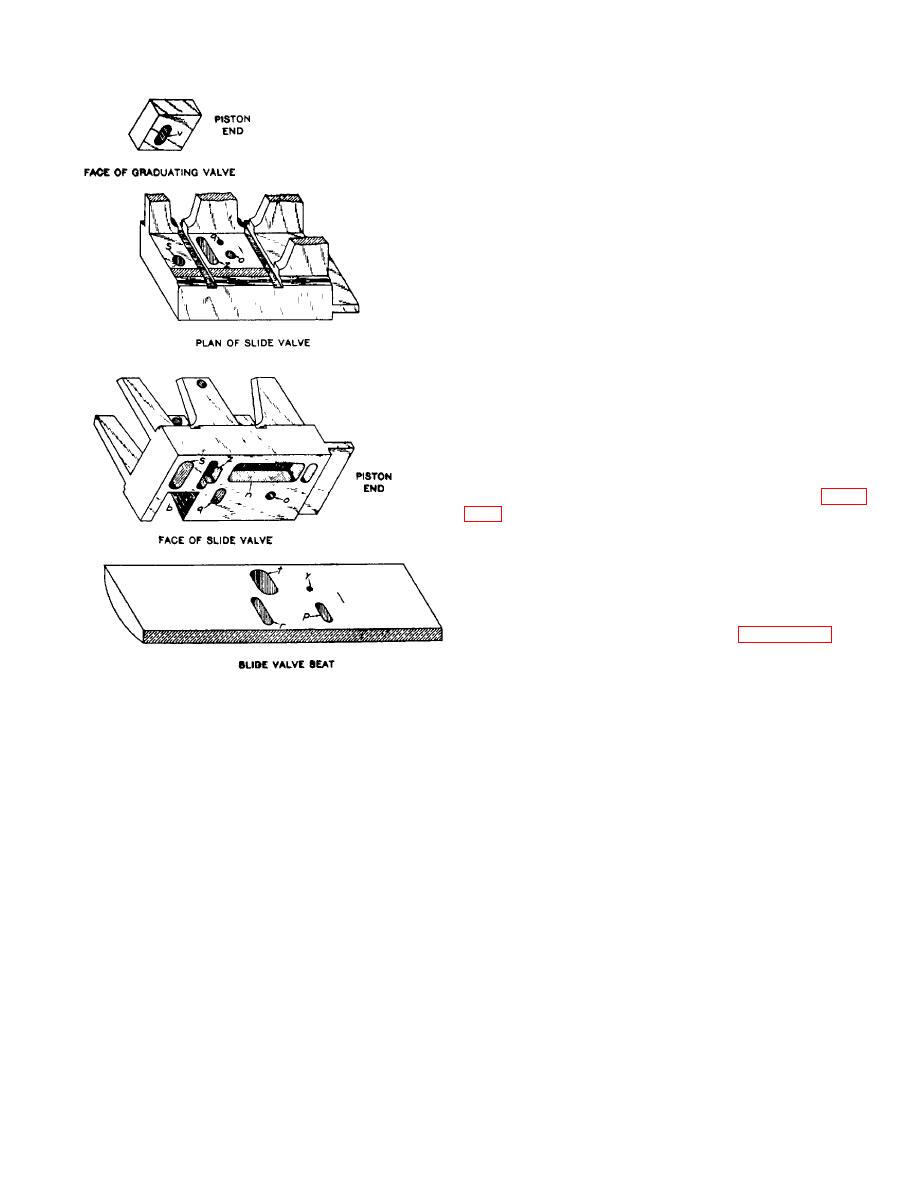

Figure 8-33. Isometric views of triple valve, slide valve

and seat, and the graduating valve.

8-41

Previous Page

Previous Page