TM 55-203

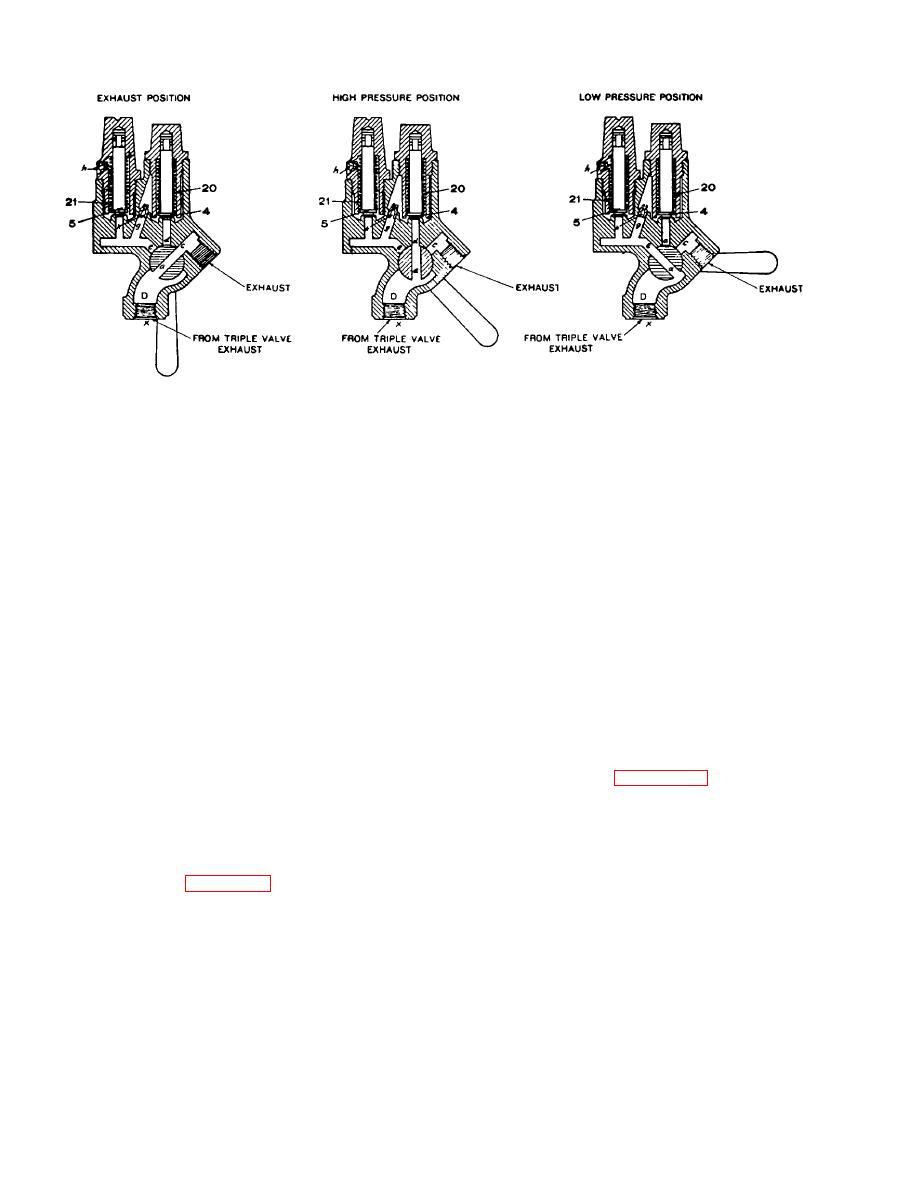

Figure 8-38. Diagrammatic views of standard pressure retaining valve.

parts are accessible for repair or replacement without

valves are in series, they will close and retain 20 pounds

removing the complete device from the reservoir. In

brake cylinder pressure. The blowdown time of the

order to inspect the valve assembly and spring, it is only

brake cylinder from 50 pounds to 20 through chokes b

necessary to remove the valve stem nut.

and t is approximately 90 seconds.

(2) Handle. The handle is made in two parts

(c) In low pressure position, handle 5 is turned to

which are pivoted to impart travel to the variable

the horizontal position marked LP. The triple valve

opening vent valve, thereby unseating the latter,

exhaust is through strainer 25, chamber A, past low

permitting the air to discharge from the reservoir. The

pressure valve 4, through choke b, chamber D, port g in

amount of travel of the variable opening vent valve

cock key 6, and past wasp excluder 22 to atmosphere

determines the rate of blowdown. A light or short pull on

Valve 4 will close to retain 10 pounds pressure in the

the hand rod results in a slow rate of discharge of

brake cylinder. The blowdown time of the cylinder from

auxiliary reservoir air, whereas a heavier pull, moving

50 pounds to 10 pounds through choke b is

the valve to its maximum open position, will cause

approximately 60 seconds.

auxiliary reservoir pressure to be exhausted from 70

pounds in approximately 3 seconds. This valve is

(d) In slow -direct exhaust position, handle 5 is

operated in the same manner as the old, by hand rods

turned to the position marked SD, 45 degrees above

from either side of the car, and being fitted with 1/2-inch

horizontal. The triple valve exhaust is through choke a,

pipe stud, is completely interchangeable with the old.

port g in cock key 6, and past wasp excluder 22 to

atmosphere. The blowdown time of the brake cylinder

from 50 pounds to 10 pounds is approximately 86

angle cock, one of which is installed at each end of the

seconds; however, brake cylinder exhaust continues

brake pipe as shown. The cock is open with the handle

until all pressure is vented.

parallel to the pipe line, as illustrated, and closed with

the handle crosswise or at right angles to the pipe line.

i. Variable Release Valve

The handle may be removed independent of the socket.

After driving out the hinge pin, the handle may be easily

removed by first depressing it and then sliding it forward

reservoir release valve which is of the variable reduction

to permit the web to clear the

type with a maximum rate of reduction that permits the

rapid depletion of auxiliary reservoir pressure. This

valve is installed horizontally, providing greater

clearance than the vertical type valve; and the internal

8-44

Previous Page

Previous Page