TM 55-203

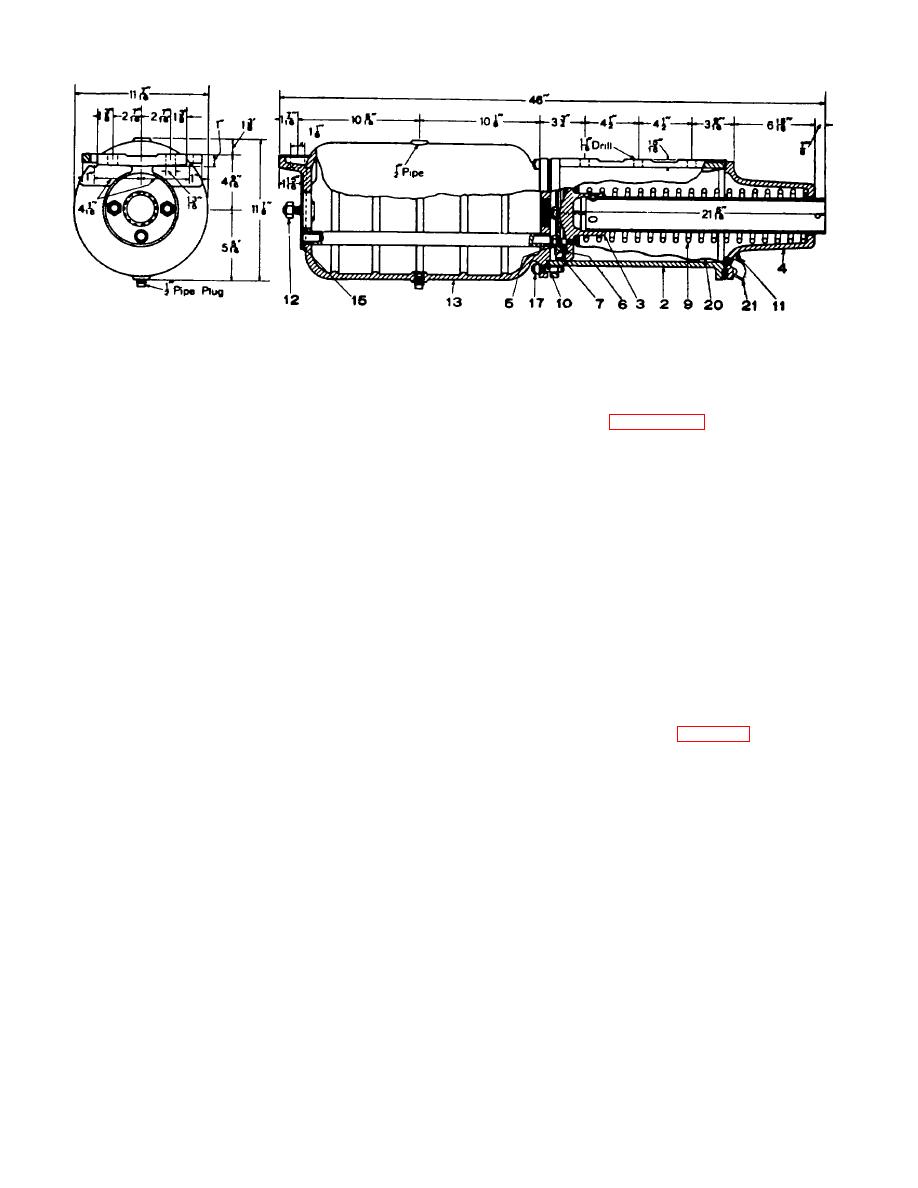

Figure 8-34. Sectional and end view 8 -by 12-inch freight brake cylinder and reservoir combined.

restricted so that release of the brake is slower than in

(5) Brake cylinder pressures. Spring 21 is

low pressure position.

capable of retaining a pressure of 10 pounds in the

g. Vent Protector and Improved Wasp Excluder for

brake cylinder. As long as the pressure of the air from

the brake cylinder is greater than this, valve 5 is

unseated and the air exhausts to the atmosphere

retaining valve with a vent protector (26) and an

through the vent port which, being ,small, makes the

improved wasp excluder (23). The vent protector is

release of the brake much slower than when the

molded Wabco and fits tightly over the low pressure

retaining valve is not used. When the pressure has

capnut to protect the small vent port against the

been reduced to 10 pounds, it is no longer able to hold

entrance of moisture which may cause corrosion and

valve 5 off its seat and the valve then closes and the

consequent restriction or stoppage of the port. The

remaining 10 pounds is retained in the brake cylinder

improved wasp excluder contains a flexible Wabco disc

until the handle 5 is turned down. Failure of the

which normally maintains a seal against the entrance of

pressure retaining valve to hold air in the brake cylinder

water and wasps, but flexes readily to permit free

generally is due to a leak in the connecting pipe, a

exhaust of brake cylinder air through the retaining valve

frequent seat of trouble being at the union; it may also

exhaust. The excluder is applied to the tapped exhaust

be due to a leak in the brake cylinders or in the retaining

opening by a hollow capscrew, having a cross port

valve, but seldom in the latter. When it is desired to

through which air passes to the excluder exhaust. Both

retain high pressure in the cylinder, the handle is placed

the vent protector and the wasp excluder are applicable

in the intermediate position marked HP. In this position,

to retaining valves in service.

passage a connects chamber D with port d so that the

h. Four-Position Release Control Retainer

air pressure must lift valve 4 against the 10-pound value

(1) Features.

The four-position type of

of spring 20. The air then 'passes through choke g to

release control retainer (fig 8-40), accepted as a

valve 5, which will be lifted from its seat against the 10-

recommended practice by the AAR and acceptable on

pound value of its spring 21, resulting in a pressure of

cars in interchange service in CONUS has the same

10 pounds in the spring chamber over valve 4. With 10

features of the AAR standard retaining valve, plus a

pounds air pressure plus 10 pounds spring pressure

fourth position which affords a slowdown release of

acting above valve 4, pressure of 20 pounds is required

brake cylinder pressure from 50 pounds to 10 pounds in

to unseat this valve. Consequently, 20 pounds air

approximately 86 seconds.

The purpose of this

pressure will be retained in the brake cylinder. The air

additional position is to provide a better control of slack

which is vented to atmosphere in this position passes

in long freight trains during release of the brakes while

valve 4, through choke k, valve 5 and through choke h.

the train is in motion, especially in cases where trains

In passing through both chokes k and h, the flow of air is

are operated over rolling country.

The use

8-42

Previous Page

Previous Page