TM 55-203

of the airbrake system, thereby protecting the triple valve,

the use of the branch pipe tee will materially assist in

preventing the excessive deposit of moisture in the branch

pipe sometimes occasioned in charging and testing drains

from poorly designed yard plants, or because the

locomotive has insufficient reservoir capacity or cooling

pipe to insure precipitation of the water before passing to

the brake system. This fitting has the interior coring so

designed that the outlet from the brake pipe to the branch

pipe is at the top. Thus, as air enters at K from the brake

pipe it flows upward into chamber L and thence through the

pipe opening at the bottom to the branch pipe, the moisture

and heavy particles of dirt passing on through the brake

pipe.

which there is one, 1 1/4-inch size in the branch pipe,

should be placed where it can easily be reached but

protected from accidental closing. This cock, when closed,

cuts off communication between the brake pipe and the

triple valve. The handle should be in such a position that,

as affected by vibration, it would tend to jar open instead of

shut.

m.

the brake pipe continuous throughout the train. When cars

are being separated, as in switching, the angle cocks

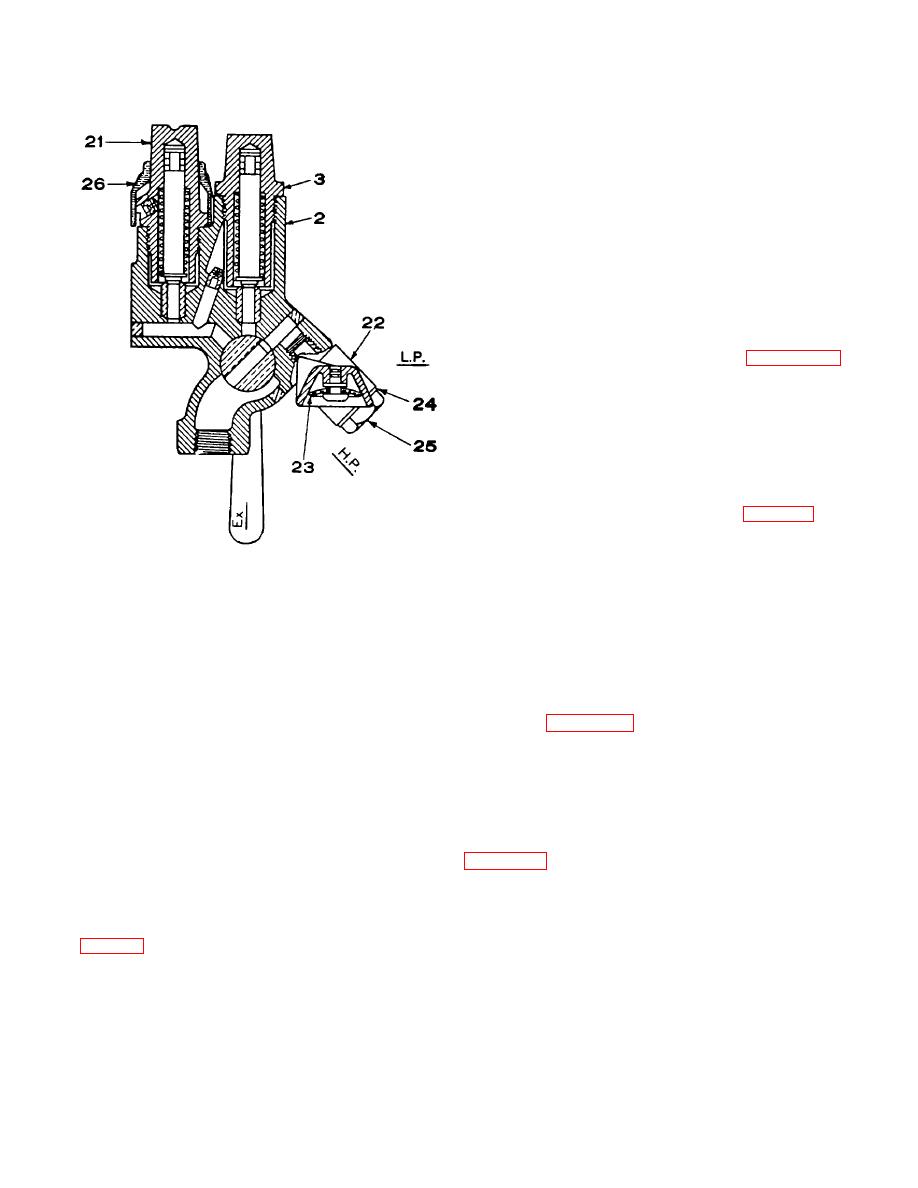

Figure 8-39. Sectional view of retaining valve with

should be closed and the hose should be uncoupled by

vent protector and improved wasp excluder.

hand, to prevent rupture or damage. Failure to uncouple

by hand causes shifting and breaking of the brake pipe as

socket lugs. The handle, of course, locks in both open and

well as damage to the coupling gasket and hose.

closed positions. When so locked, it is necessary to

slightly raise the handle before it can be turned, thus

8-23. Operation of Equipment

insuring against accidental opening or closing by being

a. General. As it is impossible to show all the ports

stepped upon, flying missiles, or loose rods and chains. An

and connecting passageways in the graduating valve, slide

extension with a U-bolt groove to the brake pipe end of the

valve, and seat by any single section taken through the

angle cock serves to support the brake pipe entering the

triple valve, figures 8-45 through 8-50 illustrate in a purely

angle cock while the groove in the extension permits the

diagrammatic way the relations of the various parts to each

angle cock to be positively attached to the hanger bracket.

other, for the different positions of the triple valve piston.

The hinge portion has been strengthened and the size of

The actual proportions and mechanical construction of the

the hinge pin increased to provide a larger bearing area. A

parts have been disregarded where necessary to make the

split type socket is used and the rivet pinhole for locking

connections 'and operation more easily understood.

the socket to the key is drilled through the split portion,

engaging a notched out cavity in the square of the key.

b. Full Release and Charging Position. As shown in

These changes provide greater strength and closer fit of

the hinge portion, and a close and permanent fit between

through passages a and e, cylinder cap ports f and g to

the 'handle socket and the cock key.

chamber H on the face of the triple valve piston; thence

through feed groove i, now open to chamber R above the

k Branch Pipe Tee. The purpose of the branch pipe

slide valve, which is always in free communication with the

tee (fig 8-42) is to prevent moisture that may be deposited

auxiliary reservoir. Air flows from

in the brake pipe, from any cause, draining into the branch

pipe connection and from thence into the triple valve.

While the centrifugal dirt collector has proved very efficient

in collecting moisture and dirt from the piping

8-45

Previous Page

Previous Page