TM 55-203

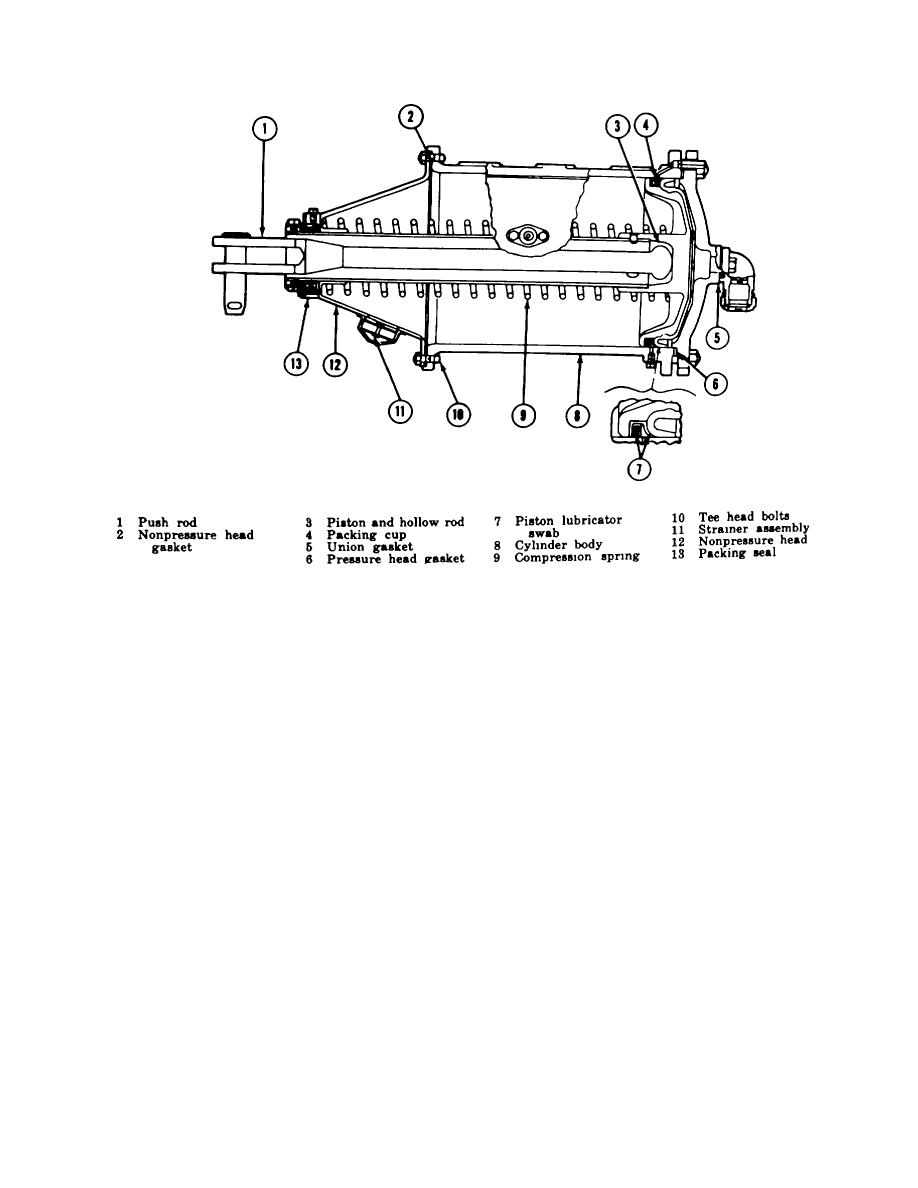

Figure 8-28. AB brake cylinder, showing air pipe connection when used with automatic slack adjuster.

b. Cleaning, Inspection, and Maintenance

(a) Submerge the piston lubricator in a tank

(1) Blow all dirt out of the nonpressure head

of solvent for a few minutes; then loosen the lubricator

and strainer.

swab in its groove with a thin round edge blade. Return

(2) Using a scraper and solvent, clean the seal

the lubricator swab to the solvent tank long enough to

recess in the nonpressure head gasket face.

dissolve the grease.

(3) With a tile, break any sharp edges from the

(b) Brush the outer surface of the lubricator

ends of the opening in the nonpressure head 'which

swab with a handbrush and blow dry with compressed

guides the hollow rod.

air.

(4) Clean the piston and the hollow rod,

(c) Renew the lubricator swab if it is

removing any rust or rough surfaces; use emery cloth if

,damaged, worn out, or in such a condition that it cannot

necessary.

be loosened and raised in its groove to make a full

(5) Examine the compression spring. If rust

contact against the cylinder wall.

,spots are found, clean them with emery cloth and coat

(d) Submerge the clean lubricator in a tank

the spring with a rust preventive.

of oil. Soak in the oil for at least 10 minutes and allow it

(6) Clean the seal ring retaining plate and the

to drain for about 10 minutes This will saturate the

seal rings, renewing any ring which does not close firmly

lubricator swab with oil and thereby prevent it from

on the hollow rod.

absorbing the brake cylinder lubricant.

(7) Thoroughly clean the packing cup (4) with

solvent and clean the piston lubricator as follows:

8-33

Previous Page

Previous Page