TM 55-203

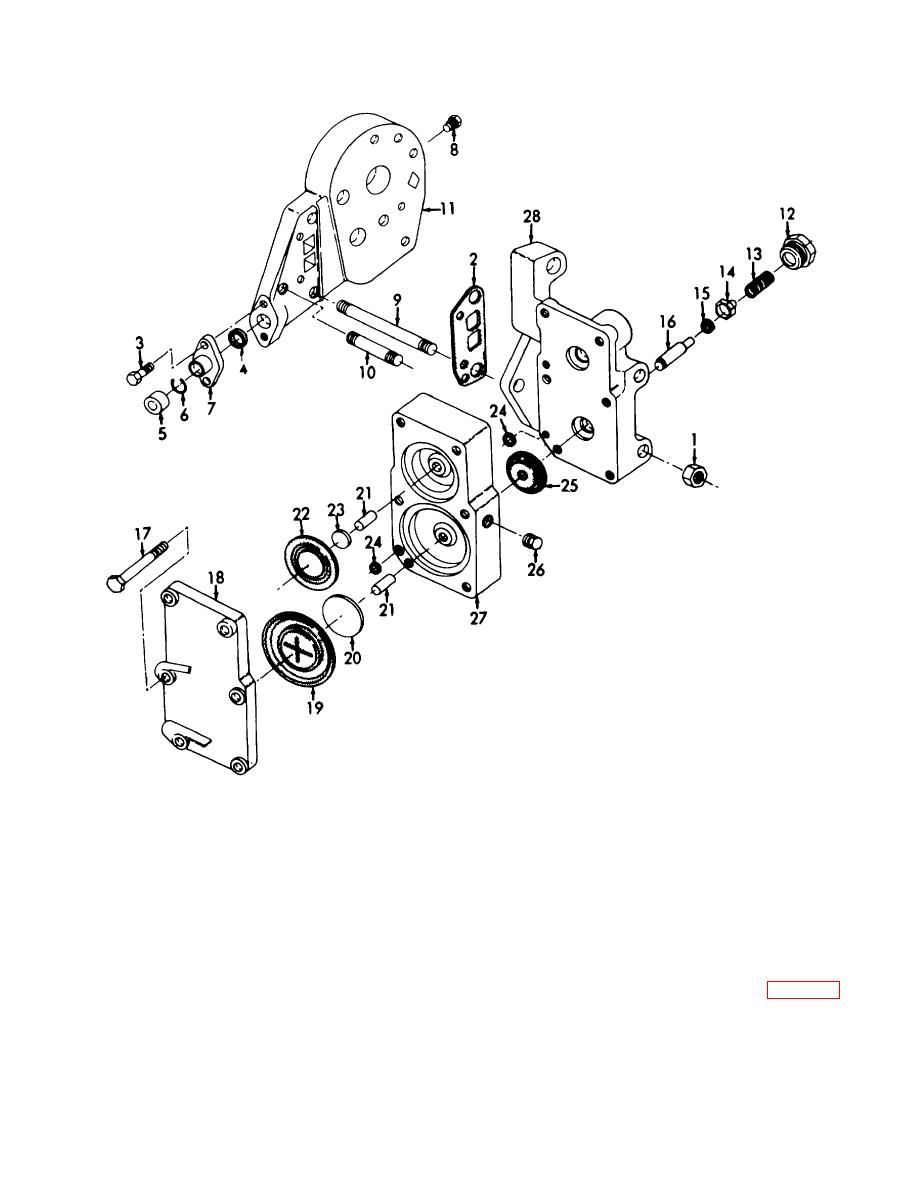

Figure 8-26. Filling piece and selector valve portion.

c. Cleaning. Wash all metal parts in approved

to remove any remaining dirt and to give them a polish.

(2) Check the piston bushing for ring size by

solvent that will dissolve oil and grease without

using a cylinder gage.

abrasion. Dip all gaskets and rubber seated parts in

(3) Remove the filter felt in choke (3). Clean

approved solvent to assist in removal of grease and dirt

and replace or renew if damaged. If the choke is the

and immediately wipe dry after cleaning. Do not soak

earlier type which does not have a filter felt, replace with

the parts in the cleaning fluid. Blow out all air passages

the latest design.

with compressed air.

(4) Reconditioning of the slide valve and piston

d. Inspection and Maintenance

is the same as for the AB control valve (para 8-15b(4)

(1) Replace all gaskets which have broken or

and (6)).

flattened beads or any that reveal cracks or cuts on

diaphragm or sealing surfaces.

Brush serviceable

gaskets with a soft bristle brush (such as a shoe brush)

8-31

Previous Page

Previous Page