TM 55-203

f. Performance of Code of Tests.

Install

(5) Inspect springs (8), (10), and (11) for rust

pits, distortion, breaks, cracks, or permanent set.

reconditioned valve on test rack and perform code of

Renew all springs that are defective.

tests in accordance with TM 552023.

e. Assembly of Parts to Body

8-18.

Shop Maintenance of AB Brake Cylinder

(1) Press the side of piston ring opposite the

scarf to the bottom of the ring groove. Apply three

a. Disassembly

drops of lubricating oil through the ring scarf opening.

(1) Remove shipping cap and place piston

Restore the ring to normal position and rotate ring in

assembly on a clean workbench.

groove to distribute the oil. Position the ring scarf

(2) Remove packing cup (4) (fig 8-28) with a

approximately 1 inch on either side of piston top center.

wood tool about I inch wide and 1/8 inch thick, with

rounded edges to prevent damage to packing cup and

(2) Apply a few drops of lubricating oil to piston

piston lubricator.

bushing and distribute evenly over the entire surface.

(3) Place piston and nonpressure head in a

Distribute one drop of oil on the collar at the piston

holding fixture which will hold the compression spring

spring end of piston, then insert piston and slide valve in

partially compressed.

the body.

(4) Remove collar from end of hollow rod

(3), then remove retaining plate and packing

(3) Assemble balance of parts in reverse of

seal (13).

removal, using new parts as required.

(5) Remove

nonpressure

head

and

compression spring (9) from the hollow rod.

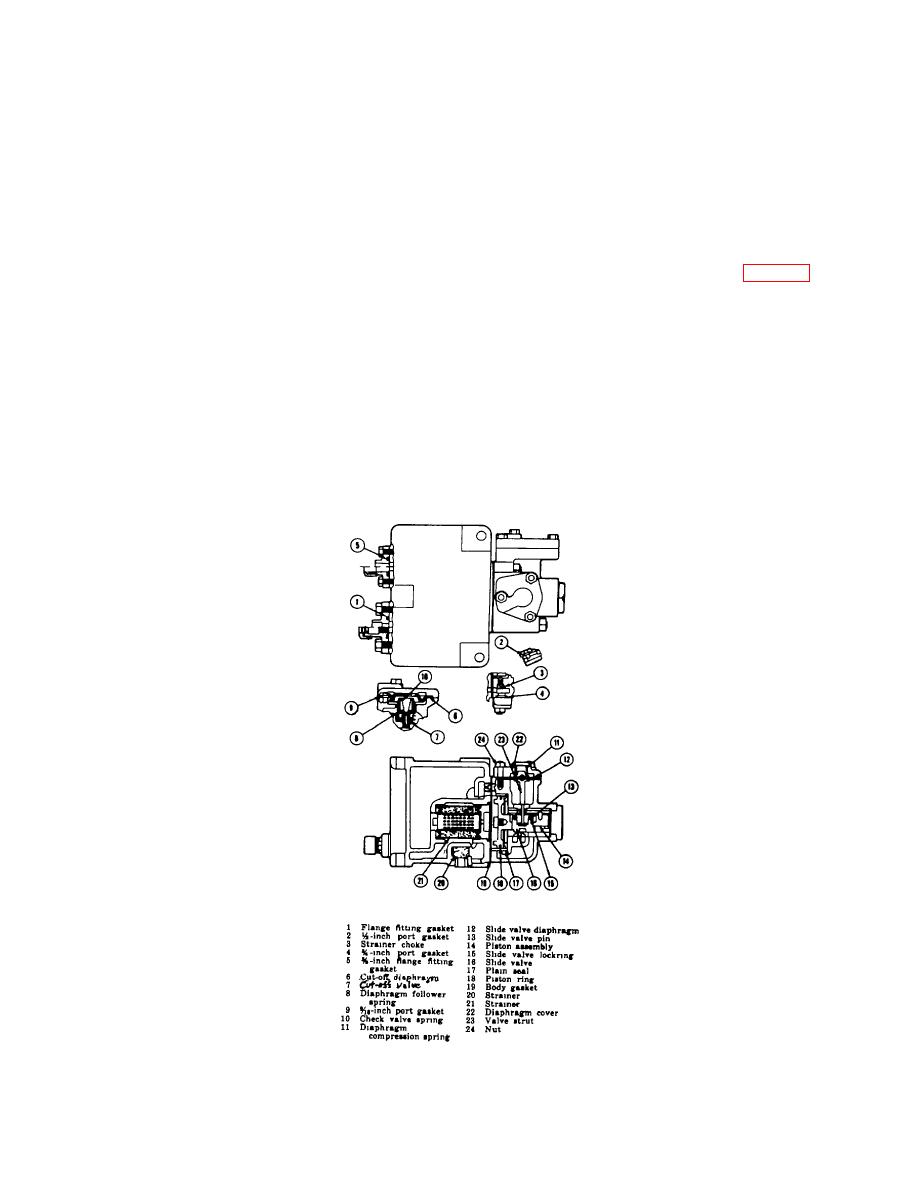

Figure 8-27. Assembly view of A-2-A qutck-serice valve.

8-32

Previous Page

Previous Page