TM 55-203

(3) Remove lock, lock lifter, and knuckle thrower.

(4) Remove cotter keys or bolts from draft key.

(5) Drift out the draft key from tapered end.

(6) Slide the coupler backward until two thirds out.

(7) Place a long bar or pipe immediately behind the

coupler head, under the thickest portion of the shank, and

with two men holding the bar or pipe in one hand, each

side, using the other hand to balance the coupler, lift it out

and lower to the ground.

(8) Remove yoke, draft gear, etc., as required (para 6-4b).

7-6. Couplers for Oversea Railway Equipment

With few exceptions, hook-and-link and Willison couplers

set at 41 inches coupler height predominate in oversea

areas. The exceptions are those areas such as Korea,

Japan, and China where AAR-type automatic couplers are

used. As stated previously, neither hook-and-link nor

Willison couplers transmit buff directly to the center sill

through draft gear. Buff loads are taken up by two side

buffers at coupler height above the top of the rail. Each

buffer is set approximately 35 inches off the longitudinal

centerline of the car. Design loads are fixed for both

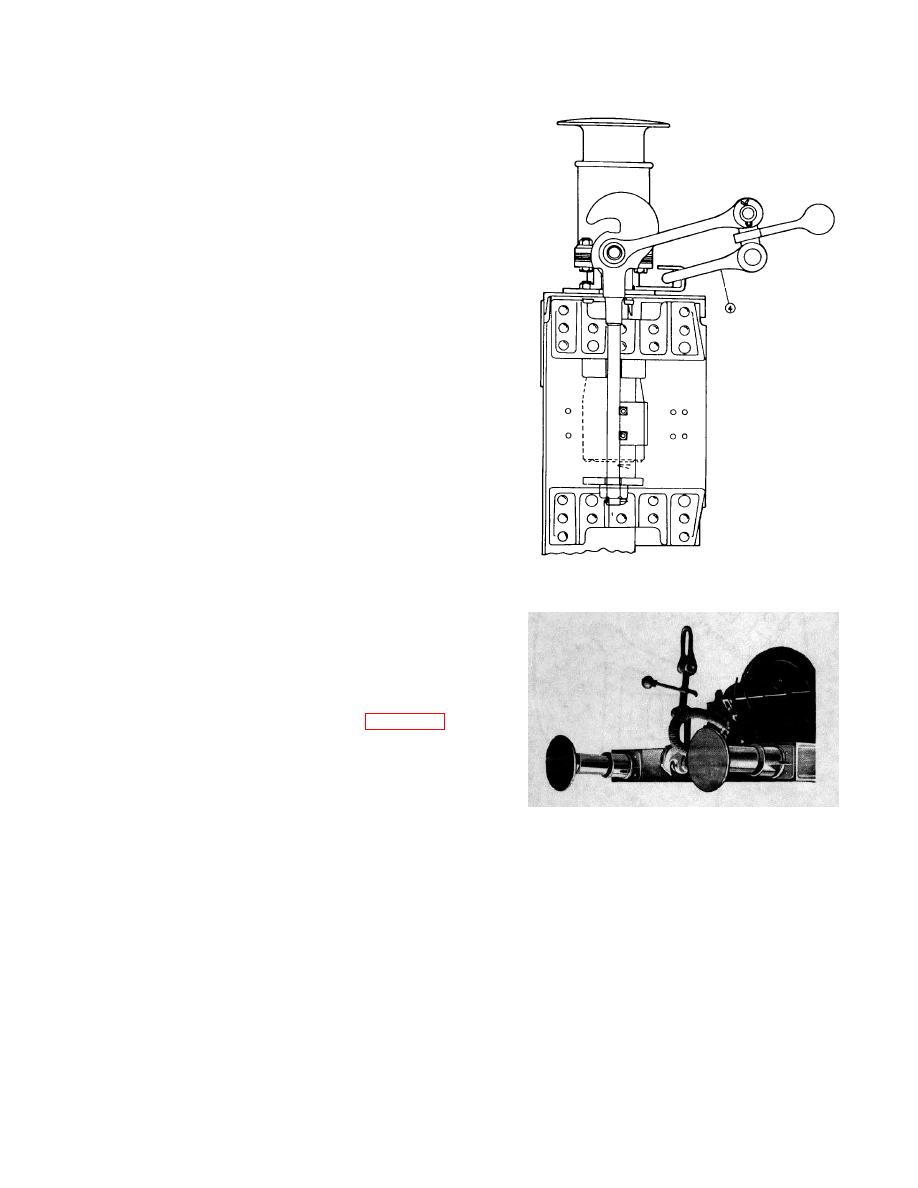

Figure 7-5. Hook and link (screw) coupler, buffer,

buffers and the hook and links of the coupler. This design

and draft gear.

establishes the maximum drawbar pull allowed when

fixing train tonnage' , and the useful life of the coupler is

s

directly related to the amount of misuse brought about by

overloading. One of the outstanding characteristics of the

hook-and link coupler is that its design provides for no

built-in slack between cars. Links are turned tight by

turnbuckles, thus losing all slack. These two coupling

devices are illustrated in figures 75 and 7-6. Figure 7-6

shows side buffer arrangement.

7-7. Hook-and-Link Couplers

a. General. The standard European coupler consists

of three main parts on each end of the car. These parts

Figure 7-6. Side buffers

are a screw coupling, a draw hook, and two buffer

of the clevis, screw and lever, and the shackle. Each

assemblies, illustrated in figure 7-. The draw hook forms

buffer assembly consists of a housing which is attached to

a part of the underframe of the car. The screw coupling is

the framework of the craft and in which is housed a

mounted at the base of the hook. The two buffer

spring-loaded section, extending out of the housing.

assemblies are located one on each side of the hook and

screw coupling toward the outer sides of the car, as

b. Operation. When cars are coupled, the shackle of

shown. The screw coupling consists

the screw coupling on one car is

7-4

Previous Page

Previous Page