TM 55-203

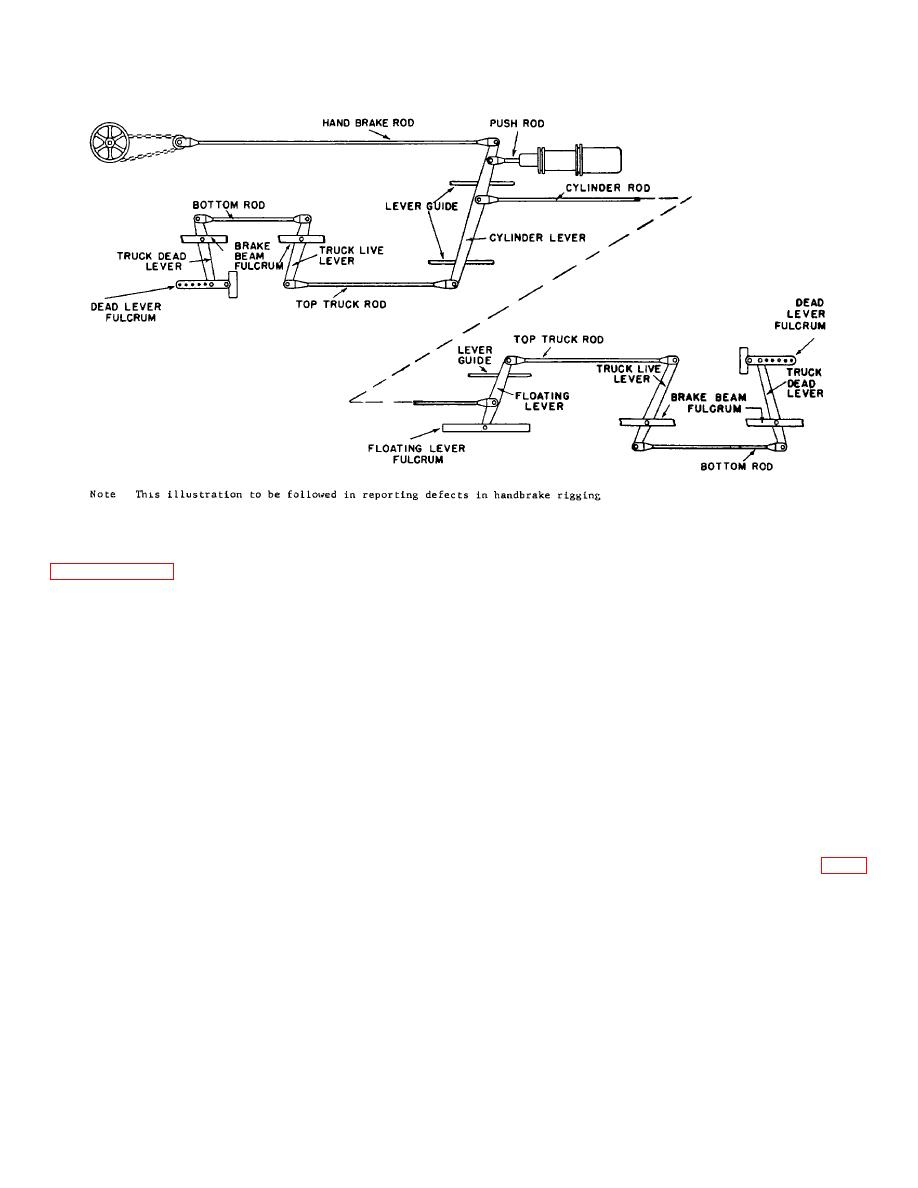

Figure 8-1. Foundation brake gear diagram.

engaging the notches. A single lever serves to take up

route in service. Maintenance is described in

slack on both trucks. To adjust piston travel: pull the

handle of the lever as far as it will go, then release. To

are described below.

release slack: push up pawl, then push back handle as

far as it will go.

b. Type 1. One type is provided with a notched

pull rod at each end of the car which is connected to the

d. Type 3. A third type is provided with a rotating

dead lever. To adjust piston travel: pull straight on the

square shaft, which is placed in a horizontal position

handle which is located on the right side of the coupler

under the car body, extending out under the outer sill of

and let go. A pawl on the notched pull rod locks when

the car. Two holes are drilled through the end of the

the rod is pulled as far as it will go. Then go to the

square shaft. A short bar can be inserted in the hole on

opposite end of the car and repeat the operation. To

any of the four sides. A pawl wheel is 'placed on the

release slack to change brakeshoes, pull handle, then

shaft, and the direction -to turn shaft to take up slack is

give it 1/8 turn to right, then push back all the way. This

indicated by an arrow on the housing inclosing the pawl

gives maximum slack in the brake.

wheel. To take up slack: insert a short bar in hole in end

of shaft, and turn shaft in direction indicated by arrow as

c. Type 2. Another type is provided with a rigging

far as it will go, then release. To release slack: release

lever which extends in a horizontal position to a point

pawl and turn shaft as far as it will go in opposite

near and just under the outer ledge of the car near the

direction. Adjustments for this type are shown in figure

center, or in some applications on hopper cars it is

8-4.

located at one end. The lever actuates a notched

square bar, which has a pawl underneath the bar,

8-2

Previous Page

Previous Page