TM 55-203

c. Knuckles. Excessive knuckle play, which ,often

results from exceptional shock and jar in switching, may

cause the guard arm of the coupler to be bent out of

contour This can cause the opening of the knuckle to be

out of gage and allow the knuckle of the coupler of an

adjoining car to slip out. The distance between the guard

arm and the knuckle should meet gage requirements, not

to exceed 5 1/8 inches, as shown in figure 7-4. The

knuckle opening may be exceptionally large.

This

condition may be corrected by building up (by welding)

the knuckle where it makes contact with the lock fulcrum.

However, a new coupler may be installed under these

circumstances. If the excessive opening is due to a worn

knuckle in the knuckle pinhole, replacement of the

knuckle may be required A knuckle worn on the face or

back bearings will be condemned by gagging. Such

knuckles will be replaced. Knuckles are sometimes found

cracked down the face. Such cracks are dangerous, and

the knuckle

should be removed and replaced.

d. Knuckle Pins. Knuckle pins are frequently found

defective. When replaced, pins of the proper size must

be used. Larger pins might crack the pinhole casting, and

smaller or undersized pins will become loose and will

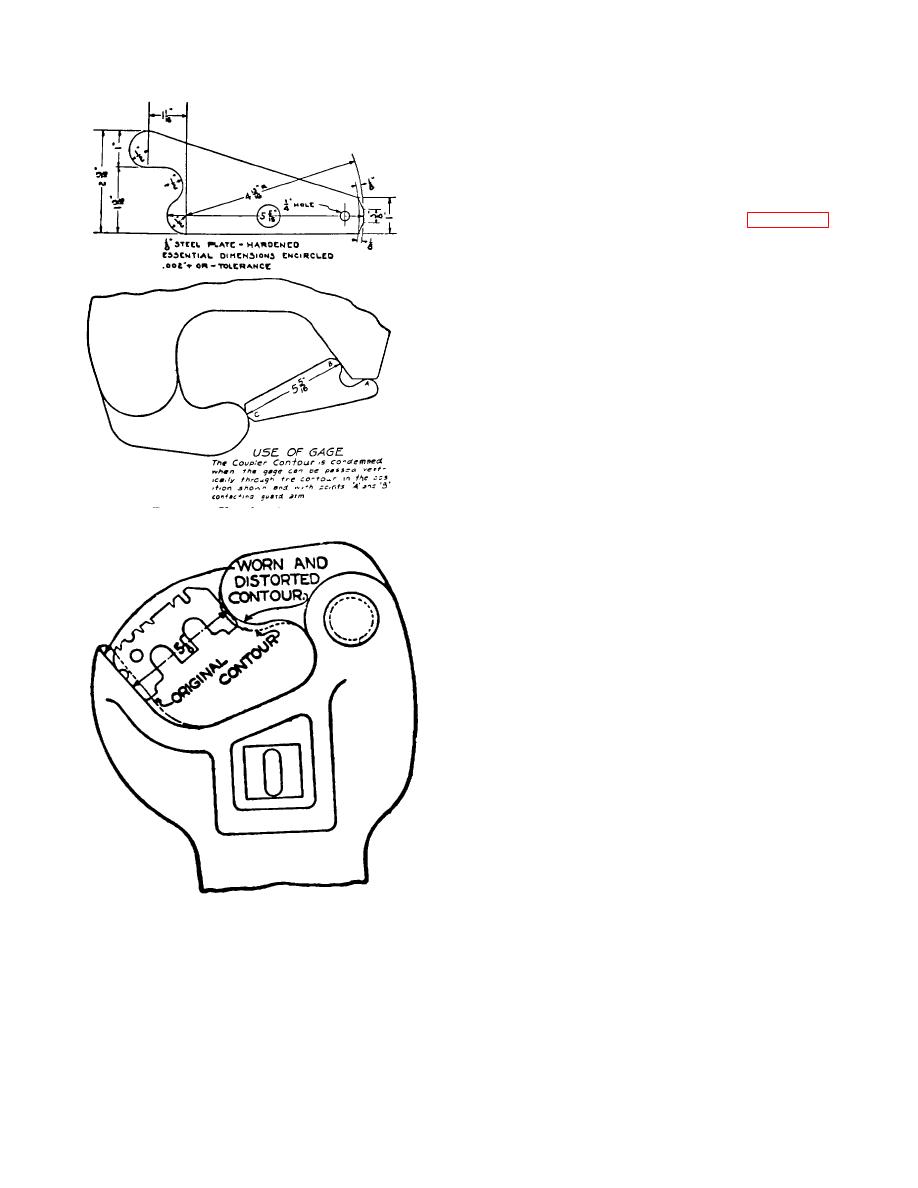

Figure 7-3. Use of contour gage.

create slack, permitting the passing of the knuckle on the

adjoining car between the knuckle and the guard arm.

Cotter keys should not be used in knuckle pins except on

fixed end gondola and hopper cars.

e. Slack. If any slack exists between the coupler butt

and the follower plate or draft gear body, the cause should

be determined and remedial action taken. Slack usually

is caused by a worn coupler butt, but may be due to

defective draft gear (chap 6). Worn coupler butts may be

built up by electric welding or shim plates inserted to

eliminate slack.

common use on Army rolling stock are attached to the

draft gear yoke by draft keys inserted laterally through

holes in the yoke and coupler shank or butt. It is

supported underneath by a coupler carrier (iron) secured

to, or part of the underframe, and a shim or wear plate

between the carrier iron and the shank of the coupler. To

remove the coupler, the following procedure is used

(assembly is in reverse order):

Figure 7-4. Use of worn limit gage.

(1) Disconnect the uncoupling lever from the

proper alinement by shimming the carrier, if its height

coupler lock lifter.

is not at least 1/2 inch in excess of the minimum

dimensions specified above, further adjustments should

(2) Remove knuckle pin and knuckle.

be made at the truck springs, center plates, or journal

boxes.

7-3

Previous Page

Previous Page