TM 55-203

or scrap sheet metal between layers.

inch of lining metal remains. Such bearings should be

e. Journal Bearing Wedges. New wedges should

tested for loose lining after broaching. This is done by

standing the bearing on end and tapping it with a

conform to the dimensional limits of current regulations.

hammer If the lining is tight, the bearing will have a

Each wedge should be checked out of the bearing and

clear, metallic ring Journal bearings should be selected

should seat properly on the crown, without pinching the

for broaching by proper inspecting and by use of

sides or resting on the lugs. If the front surface of the

appropriate gages.

wedge is bent down, it will not engage the lugs in the

(3) Bearings with lining melted off from overheating

box. Sometimes wedges are too narrow for the bearing;

in service should not be relined.

this will tend to pinch the journal and may ,cause a

(4) When wheels are removed to be turned and

hotbox. If the wedge is flat on top, it cannot rock with

when it is feasible to do so, it is good practice to return

the rotation of the axle as intended. The weight will be

bearings to service with the same journals, provided

unevenly distributed over the bearing, and too much

they are within dimensional limits and linings are tight.

weight in one place will cause sufficient friction to make

(5) Bearings should not be thrown or dropped or

the journal run hot. If the wedge exhibits a bright ridge

allowed to lie around mixed with other material.

over its entire length on top, it is reasonably sure that

(6) In transit and in storage, bearings should be

the wedge is not rocking, but is bearing rigidly against

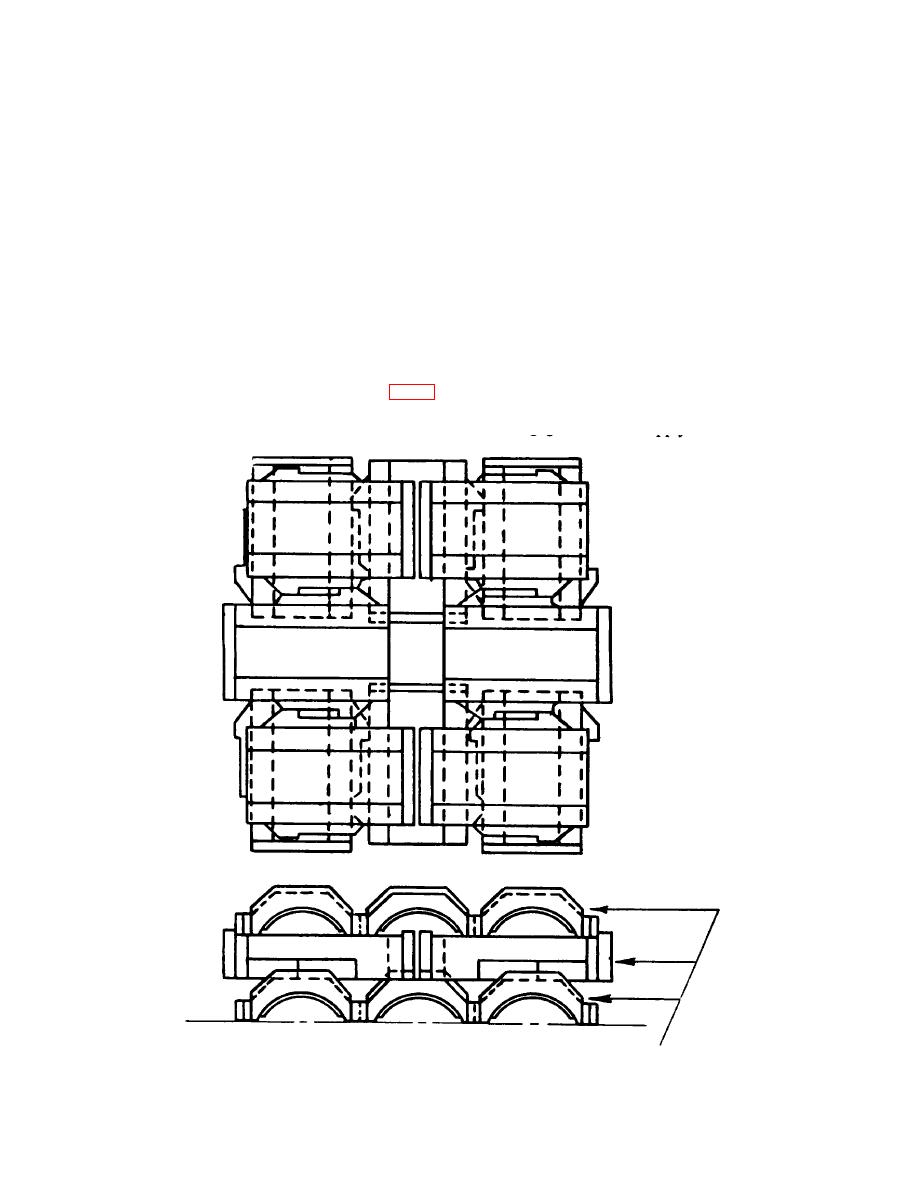

stowed or stacked to avoid damage to lining. An

the top of the journal box. The following general rules

approved method of stacking bearings is shown in figure

apply:

4-25. Bearings may also be stacked in layers with wood

Figure 4-25. Recommended method of stacking journal bearings.

4-20

Previous Page

Previous Page