TM 55-203

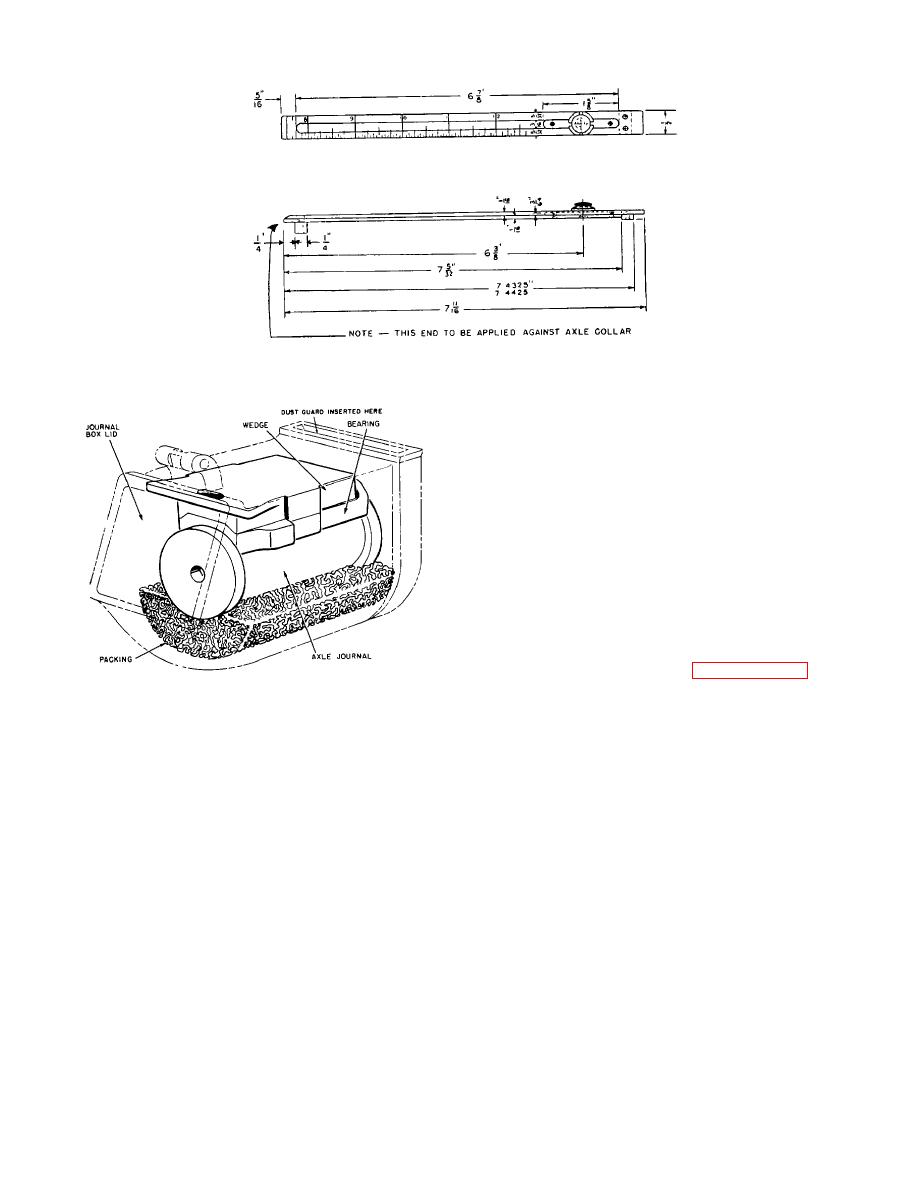

Figure 4-21. Gage to be used in measuring length of worn journals on class

A to F axles, inclusive.

wedge is held in place by projections provided for this

purpose in the cast-steel journal box top The lugs are

released when the journal box is jacked up a few inches.

d. Journal Box. The journal box packing contained in

the journal box bottom is an important part of the

bearing assembly Whether it consists of commercial

spring-type lubricating pads or cotton and/or wool waste,

when packed in the prescribed manner, it acts as a wick

and feeds lubricant to the bearing. The use of waste

packing has been discontinued on most commercial

railroads in the continental United States (CONUS),

present practice being to use AAR-approved lubricator

pads. There is increasing use of the roller bearing

journals for freight service also. Most Department of the

Army (DA)-owned rolling stock overseas has the waste-

type journals. Details concerning proper packing of

journal boxes are contained in paragraphs 4-12 through

4-18.

Figure 4-22. Typical journal box assembly.

e. Box Lid. The journal box lid closes the front of the

journal box and keeps out dust, dirt, and other foreign

built to meet specifications and are fabricated of either

matter detrimental to the operation of the journal

bronze or a .special iron. They are also provided with a

bearing. Although the lid is hung so that it will remain

babbitt metal lining, which is poured cast to face the

closed during movement of the car, it is made to open

bearing back and become an integral part of it. This

easily for servicing and inspection. The lid is hinged

combination of metals has long been considered the

from the top of the box and is spring-loaded to insure

best for solid-bearing construction. The babbit is soft,

tight closure. An attachment is provided to keep the lid

although tough and durable, and provides a highly

open when servicing operations are in progress. On

efficient bearing surface. The iron or bronze backing in

oversea cars, bolt-locked journal box lids are

turn gives support and tends to dissipate the heat

standardized to minimize pilferage of waste and brass

generated by transferring it to the box top.

journal bearings.

c. Wedge. The wedge, a companion part of the

bearing assembly, is provided to furnish limited rocker

extent worldwide for both passenger and freight cars.

anchorage for the bearing It also serves to distribute the

They require relatively little maintenance attention

weight of the car equally over the wear surface of the

beyond periodic relubrication. Additional advantages

bearing because of its rocker-bearing contour. The

are almost total elimination

4-15

Previous Page

Previous Page