TM 55-203

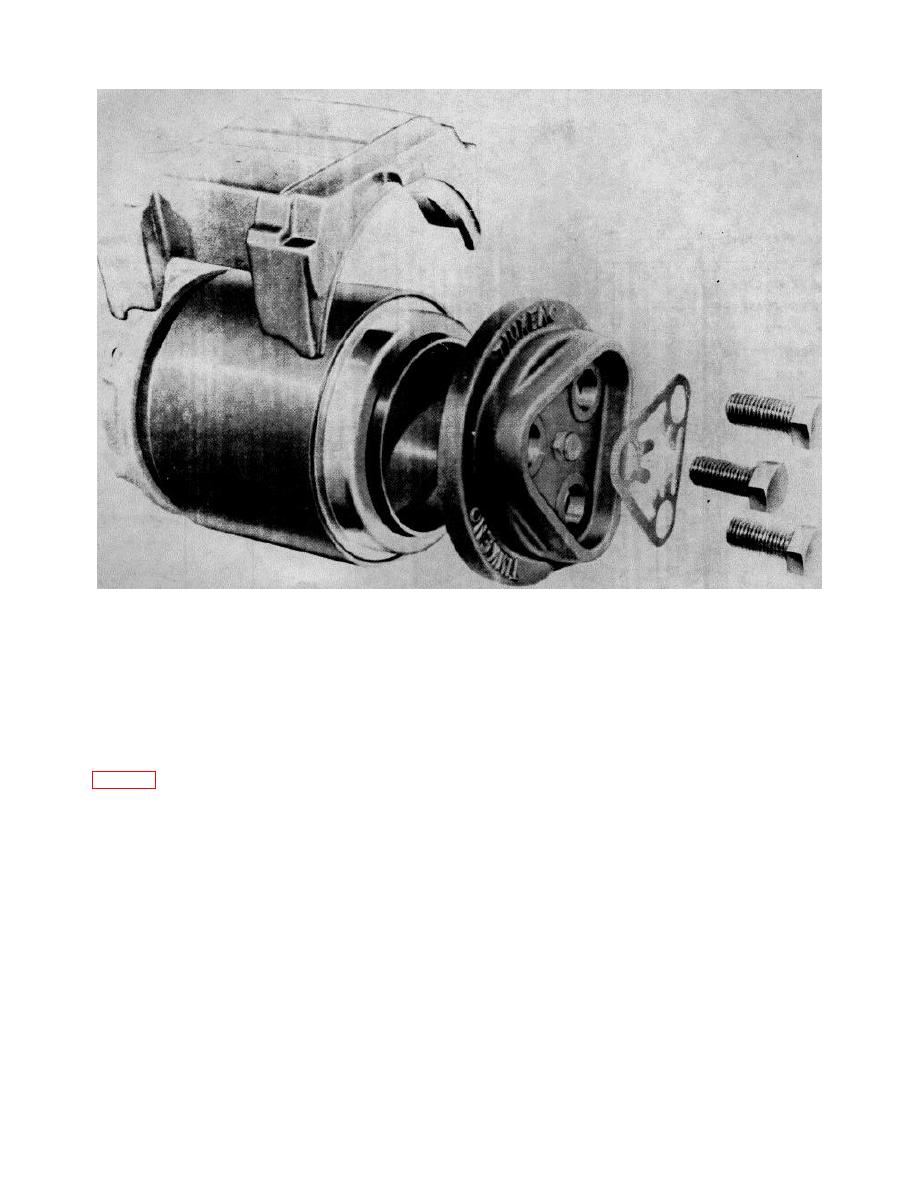

Figure 4-23(2). Heavy duty bearing assembly, application parts, exploded view.

uneven weight distribution plus faulty lubrication. Wear

4-10. Journal Care

marks will indicate whether the journal will become

Overheating (hotboxes) causes the oil in the journal box

tapered or not.

to carbonize or burn. After the oil in the packing has

b. Renewal Precautions. In the process of changing

burned, the remaining black residue sticks to the journal

wheels and/or applying new journal bearings to car

bearing and scratches or cuts the journal, which is

wheels, the following precautions will be observed.

relatively soft when hot. A "rough" journal can be

detected by feel, either by using the tips of the fingers,

(1) The surface of the journal should be smooth and

or preferably by using the pointed end of a waste grab

thoroughly clean before the bearing is applied. Abrasive

hook (fig. 4-24). It will also be very dry. When a journal

paper or cloth should not be used on or about axle

becomes scarred, it is unsafe for further service and that

journals under cars. Journal surfaces should not be

pair of wheels will be replaced.

wiped with waste.

4-11. Journal Bearings

(2) Plain journal bearings should be clean and

smooth before application. Do not use abrasive paper

a. General. Like the journal, the main cause of

or cloth for removing irregularities If necessary use a

journal bearing failure can be traced to the lack of

half-round file or scraper.

lubrication Bearing damage will occur when there is not

enough oil on the journal to overcome the effects of

(3) Apply a thin coat or car oil to the lining before

friction developed between the journal and bearing,

applying a bearing. Never wipe the lining or journal with

whether babbitt lined brass or steel roller bearing If one

waste.

end of the bearing is excessively worn, the journal

should be examined for tapering. Tapering is caused by

4-17

Previous Page

Previous Page