TM 55-203

of "hot-box" problems, better riding qualities for the car,

b. Dry or Misplaced Packing. If the packing has

and lessened wheel and truck wear. Roller bearings are

settled away from the journal for any portion of its length

manufactured by various commercial concerns in

or if the back roll is not in contact with the journal fillet, a

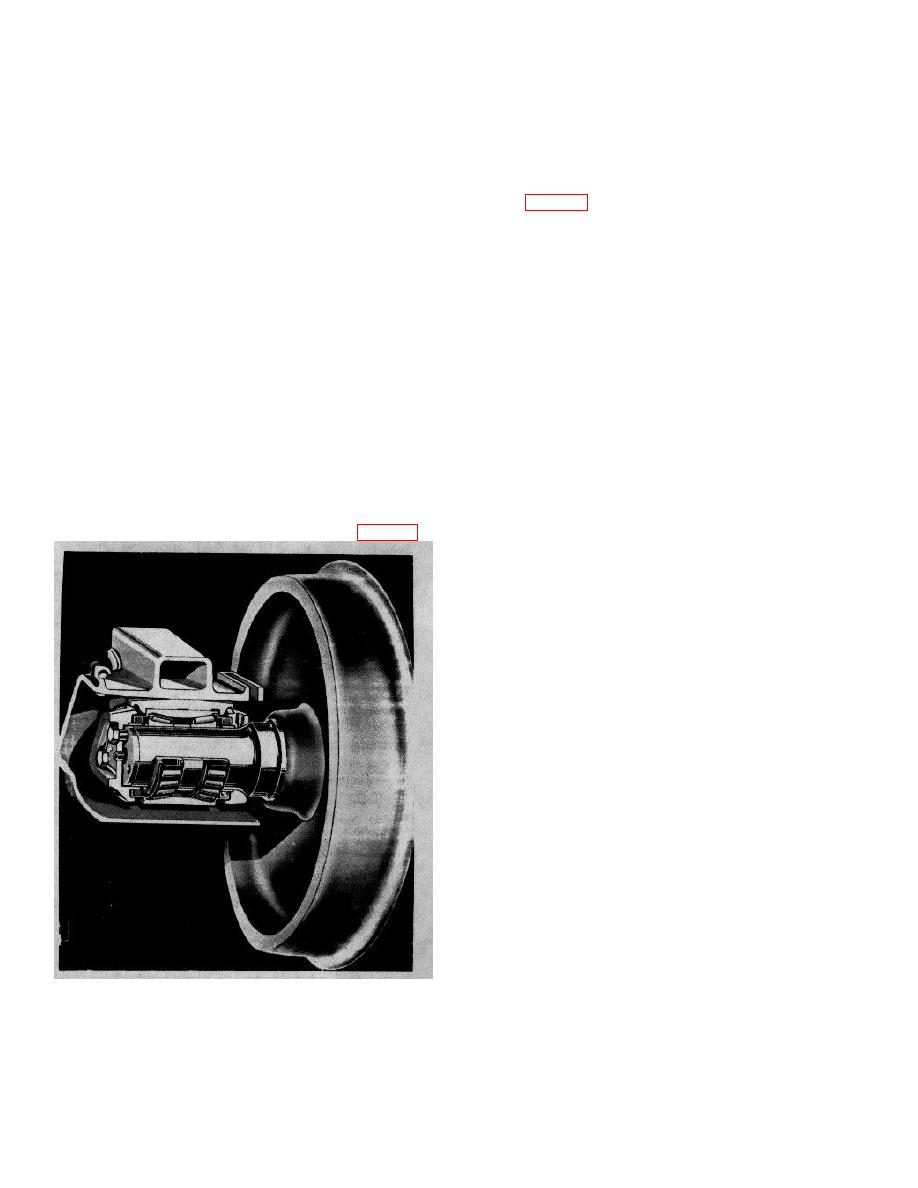

CONUS of two general types-cylindrical and tapered

dry spot develops and overheating results.

The

hard steel bearings fitted snugly to the axle journal. The

accepted method of 'detecting misplaced packling is

tapered bearing is illustrated in figure 4-23(1). The

examination with the standard packing iron or packing

component parts of another bearing are shown in figures

hook (fig 4-24). Dry packing is corrected by adding free

4-23(2) and 4-23(3).

oil. However, too much oil makes the packing soggy

and causes thread and lint to stick to a cold journal.

c. Loose or Overrun Lining. If the bearing lining is

4-9. Causes of Hotboxes

overrun, it interferes with the proper oil circulation and

prevents oil from following the journal into the load-

a. Waste Grab. Threads or particles of waste

bearing area. Loose or overrun lining can be detected

between the bearing and the journal act as an oil wipe

with the lining or waste grab hook when checking for

and cause a dry spot. Waste grab may be caused by

waste grab.

loose threads and lint wedging (a waste grab) between

d. Water in Packing. In freezing weather, water

the bearing and journal. Loose threads must be tucked

freezes in the waste threads and shuts off the capillary

under, and packing must be free from lint. Wedging is

action which carries oil to the journal. It may cause the

most likely when a standard size bearing is applied to a

packing to adhere to the journal and become badly

minimum size journal or one which is worn close to the

misplaced. Water also gets under the oil when it does

limit. Packing which is rolled up on one side of the box

not freeze and displaces oil from the back of the box

is an invitation to waste grab. Rough handling in yards

through the dust-guard well. Loose or poorly fitting lids

or severe buffing shocks in trains may cause

admit snow and cause water trouble.

displacement of the bearing on the journal for an instant,

e. Dripping Brine. Brine dripping from refrigerator

long enough for bits of waste to get under the bearing.

cars causes trouble if it enters the journal box. It is

The method of detecting waste grab is to feel along the

corrosive and can cause rough spots on journals.

edge of the bearing with the waste grab hook (fig 4-24).

f. Flat or Rough Wheels. Flat or rough wheels cause

a pounding which settles the packing away from the

journal and breaks the oil film under the bearing.

g. Overloaded Cars. Common causes of hotboxes

are overloaded cars, or cars having misplaced or shifted

lading which increases the load on one or more journal

boxes.

h. Defective Trucks. Trucks which are out of square

or which do not swivel freely owing to binding of side

bearings or dry center plates may contribute to

overheated bearings.

i. Axles. Bent axles may cause hotboxes. If an axle

is bent between wheels, the wheel tread will show

uneven wear. Bearings on bent axles will also show

tapered wear, and if allowed to continue in service may

become badly damaged by overheating. The bearing

on the other end of the axle should be examined as a

precaution if a bent axle is suspected.

j. Truck Bolster Springs and Snubbing Devices.

Defective or improperly applied coil springs and

snubbing devices may result in hotboxes.

Figure 4-23(1). Tapered roller bearing.

4-16

Previous Page

Previous Page