TM 55-203

(18) Wheels and axles are moved from the

the wheel pairs received at the wheel shop have been

boring mills and the axle lathes to the mounting press.

Inspected and marked as to disposition, they are sent

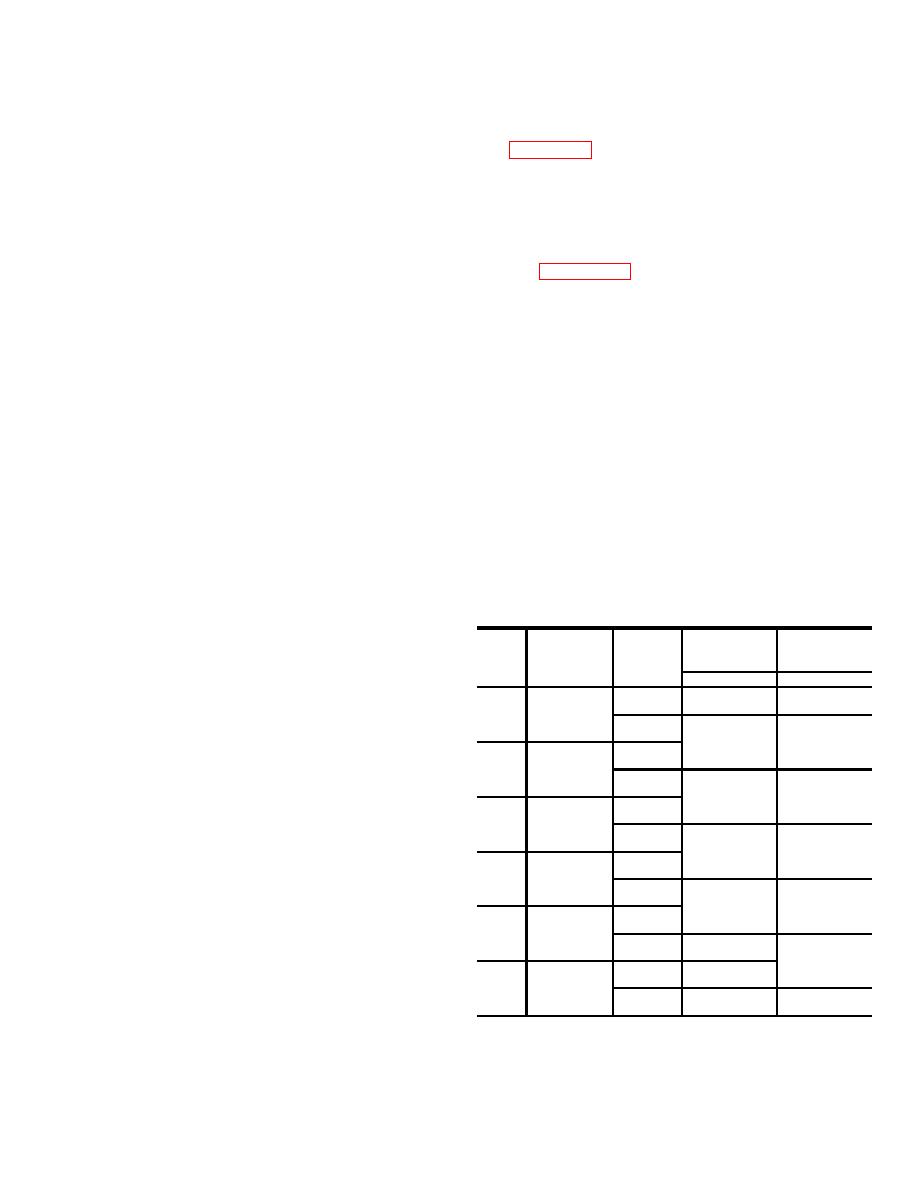

See figure 18-1 for AAR-approved mounting pressures.

through the shop in different directions depending upon

(19) Mounted wheels are given their final

the nature of the operations to be performed.

shop inspection before storage or shipment.

b.

The following outline shows a typical

(20) A protective coating is applied to axle

sequence of operations in a car wheel shop handling all

journals.

types of wheels.

(21) Finished wheel pairs are moved to

(1)

Wheel pairs are moved from the

storage or are loaded on cars for shipment.

railroad car to the demounting press.

c.

(2)

Wheels are demounted from the

flow of 100 wheel pairs and the course through the shop

axles.

taken by the parts necessary to complete them,

(3)

Axles

are

moved

from

the

including the assembly of the necessary finished parts,

demounting press to the axle lathes, axle storage, or

both new and from storage. The quantities may vary

scrap axle bin.

considerably from one shop to another, depending upon

(4)

Individual wheels are moved from the

the number of cast iron or steel wheel pairs received,

demounting press to the wheel storage or scrap wheel

whether the wheel pairs are ground, treads turned, or

bin.

journals turned; and whether diesel wheelwork is

(5) Wheel pairs are moved from the railroad

included in the shop operations. This chart shows the

car to the wheel grinder, wheel lathe, or Journal-turning

sequence of operations on wheels, axles, and wheel

lathe.

pairs.

(6)

Individual wheels are moved from

storage to the wheel boring mills.

(7)

New axles are moved from storage to

18-20. Handling Wheel Pairs

the axle lathes.

(8)

New cast iron or wrought-steel wheels

a.

It is the usual practice to transport wheel

are bored.

pairs in special cars designed and regularly assigned for

(9)

Secondhand cast iron or wrought-

wheel service, although gondolas may be used. A

steel wheels are bored

standard flatcar or gondola will accommodate

(10) New or secondhand axles are

machined.

WHEEL PRESS PRACTICE

(11) Journals on new or secondhand axles

Nominal

are burnished.

Class

Wheel

Cast Iron

Steel

of

Journal

Seat

Wheels

Wheels

(12) Journals on mounted wheel pairs are

Axle

Size

Diameter

Min - Max

Min - Max

refinished by turning and burnishing.

(13) Treads on new or secondhand cast iron

5 1/8"

30

55

50

70

A

3 3/4" x 7"

or wrought-steel wheels are ground.

5 1/2"

(14) Treads on wrought-steel wheels are

35

60

55

80

turned.

5 3/4"

B

4 1/4" x 8"

(15) New or secondhand axles are centered

6 5/16"

or recentered.

40

65

70

100

(16) Axles are inspected for defects by the

6 1/2"

Magnaflux, Magnaglo, X-ray, or Whiting method.

C

5" x 9"

7"

(17) Wheels and axles are matched for

45

70

75

110

mounting. To secure the greatest value from both the

7"

wheel seat and the hub bore, it is preferable to mount

D

5 1/2" x 10"

new wheels on secondhand axles with wheel seats

7 9/16"

50

75

80

120

reduced in diameter; and to mount secondhand or worn

7 518"

wheels with increased bore diameter on new axles or

6" x 11"

E

those with comparatively large wheel seat diameters.

8 1/4"

55

80

85

130

New wheels must never be bored for application to

8 1/8"

oversize wheel seats. The wheel bore should always be

6 1/2" x 12"

F

fitted to the axle, not the axle to the wheel bore. See

8 3/4"

90

140

figure 419 for example of selection of wheels and axles

*Nominal Wheel Seat Diameters of A A R Axles

for mounting.

No tolerances permitted below minimum or above

maximum pressures shown above

Figure 18-1. Wheel mounting pressures, in tons.

18-7

Previous Page

Previous Page