TM 55-203

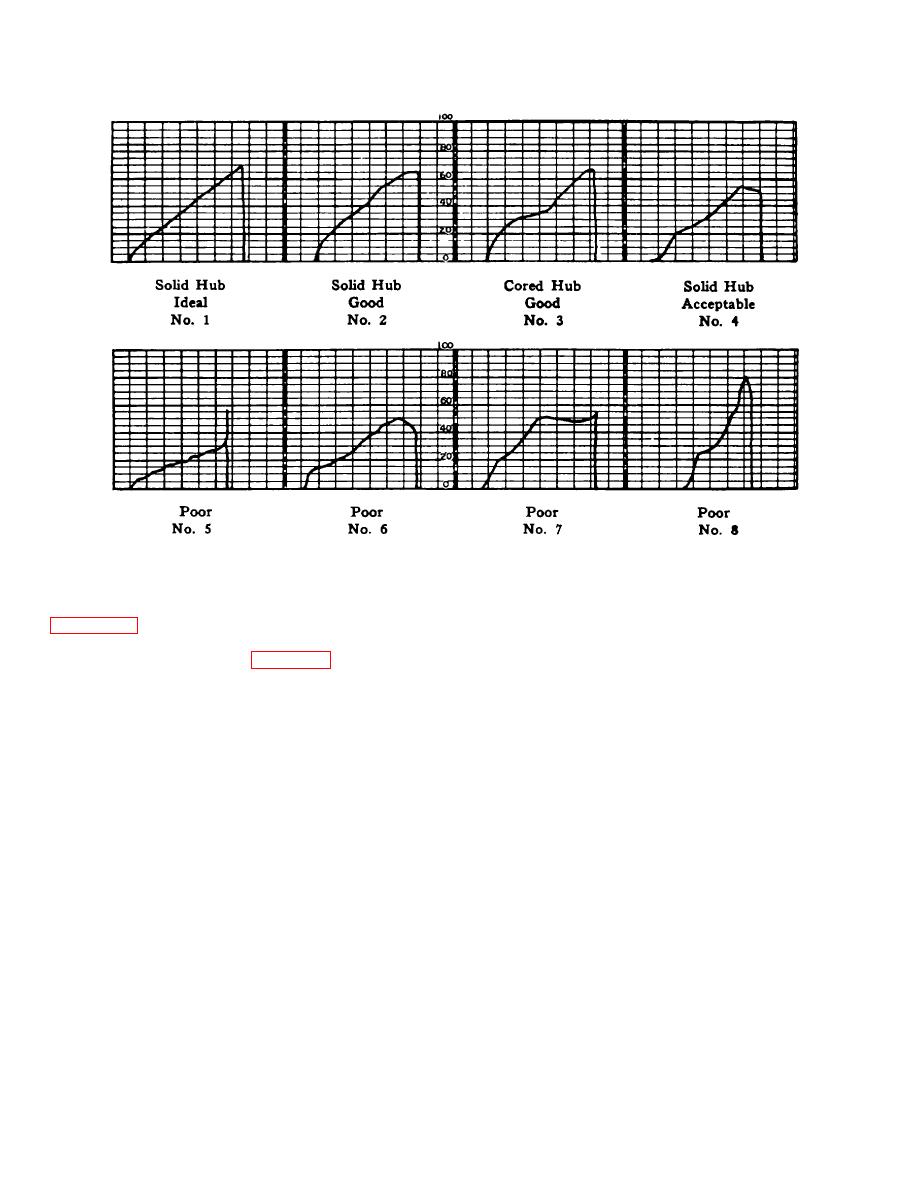

Figure 18-4. Wheel-fit pressure diagram.

c.

During mounting, the pressure gage must

of all wheel pairs be made before they are placed on

storage tracks or are loaded for shipment.

be watched and, if pressure is outside the limits given in

e.

Wheels must be mounted centrally with

plainly marked "misfit." Misfit mountings must be

corrected. The limits given in figure 18-1 apply to wheel

respect to the center of the axle. A suitable axle center

fits of the multigage fleet of Department of Army cars.

gage similar to those shown in AAR Wheel and Axle

In mounting the wheels, both Journals must be

Manual and the mounting gages shown in figures 4-18

protected with efficient guards during the entire

and 4-19 should be used. If rims and flanges do not run

operation to prevent nicking and scratching the surfaces

in a plane at right angles to the axis of the axle, the

of the journal.

wheels will take the mounting gage at only 1 or 2 of 3

equidistant points on the circumference of the wheels.

d.

Immediately before the wheels are placed

The journals and wheel treads must be checked and, if

out, must be turned to within prescribed tolerances.

on the axle, the wheel seats and the bore of the wheels

Wheels that will not take the mounting gage at any of

must be carefully cleaned and coated with a mixture of

the three points must be demounted and checked for

basic carbonate white lead and boiled linseed oil in a

diagonal bore and the axle checked to see whether it is

proportion of 12 pounds of white lead paste to 1 gallon

bent. If the axle is bent and shows a runout of more

of boiled linseed oil, thoroughly mixed. A fresh supply

than 1/4-inch at the center, it should be straightened, if

should be mixed every few days. If desired, ready-

possible. Flat spots and other forging irregularities

mixed white lead compound may be purchased in gallon

should be compensated for in measuring 1/4-inch

containers of approximately 14 pounds each Its

runout. Axles which cannot be straightened must be

specifications must comply with regulations. Wheels

scrapped.

are placed on the ends of the axle, the assembly rolled

into the press, and the axle pressed into the bore of the

f.

New wheels mounted on the same axle

wheel. Then the axle and wheels are reversed and

rolled back into the press and the process is repeated

must be of the same tape size and bear the same tape

for ,the other wheel. It is essential that a final inspection

size marking.

Secondhand wheels should be as

18-10

Previous Page

Previous Page