TM 55-203

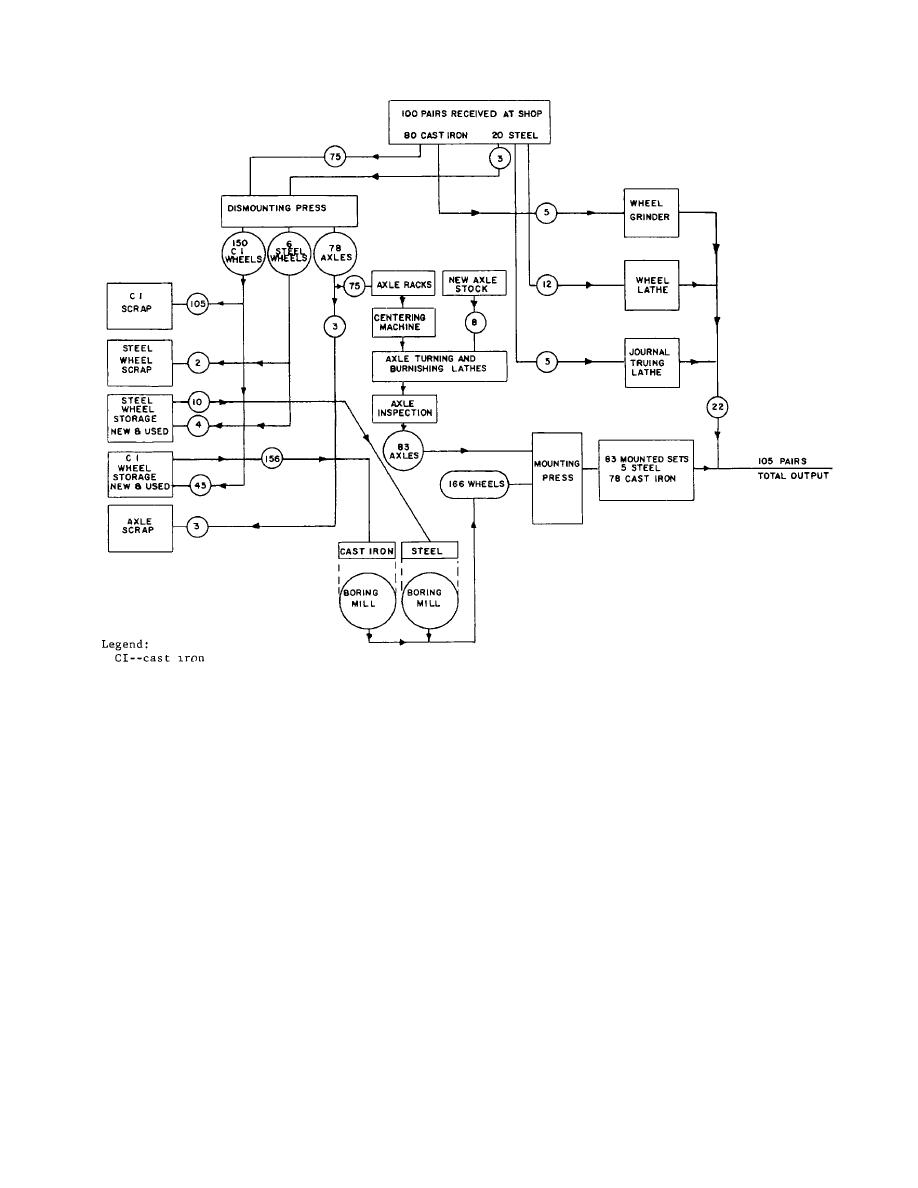

Figure 18-2. Work flow chart showing course of axles and wheels through the shop.

33-inch nominal diameter wheels should not be stored

approximately 20 wheel pairs in a single layer. A car

arriving at a wheel shop may contain a variety of wheels

with 36-inch nominal wheels. Multiple-wear wheels of

the same nominal diameter should be further

of different journal sizes and types. Some may be cast

segregated so that those having a rim thickness 1 3/4

iron or wrought-steel to be dismounted; others may

require that one or both journals be turned; or wrought-

inches or more are stored separately from those having

a rim thickness of less than 1 3/4 inches.

steel multiple or one-wear wheels may require their

treads to be turned. Wheels should be tagged or plainly

c.

Dolly cars, turntables, hoists, or cranes can

marked to show the defect. Wheels requiring similar

work should be placed together.

be used to move wheel pairs from the storage tracks to

the car wheel lathe or the journal-turning lathe. Wheel

pairs for demounting should be rolled directly from

b.

Wheels storage tracks must be spaced so

that the flanges of one pair of wheels cannot strike

storage tracks into the wheel press or should be handled

automatically to eliminate the labor which would

either the journal or the center portion of the axle of an

adjacent pair. A nick in the journal may cause a hotbox,

normally be required.

and a nick in the center portion of an axle may lead to

breakage. Spacing pairs of rails 6 inches on center will

18-21. Handling Axles

prevent (nicking as the flanges will then strike the hub of

a.

New axles can be unloaded from cars to

the next wheel. To prevent axles and flanges from

contacting wheels of different nominal diameters,

storage racks by a locomotive crane, a mobile crane

wheels should be segregated so that those widely

truck, forklift trucks, or a hoist, depending on the type of

varying diameters are not stored together. For example,

car and the method of loading.

18-8

Previous Page

Previous Page