TM 55-203

together at the overlapped seams. Tanks vary in design

in relation to commodity transported Some, like Army-

owned tank cars used for the transportation of petroleum

products, are constructed to provide one large

compartment (fig 2-6), other types are divided into

several compartments so as to carry different kinds of

liquids at the same time.

9-33. Construction Features

a. General. The superstructures of tank cars

(shells) must be constructed of materials which resist

corrosion, or be lined with corrosion-resistant material.

For this reason, tank shells are built of alloyed steel,

nickel steel, or aluminum. Insulation is sometimes

required to maintain an even temperature for certain

commodities.

Some viscous liquids require the

application of heat to facilitate unloading. This normally

is accomplished by steam coils installed inside the tank

shell.

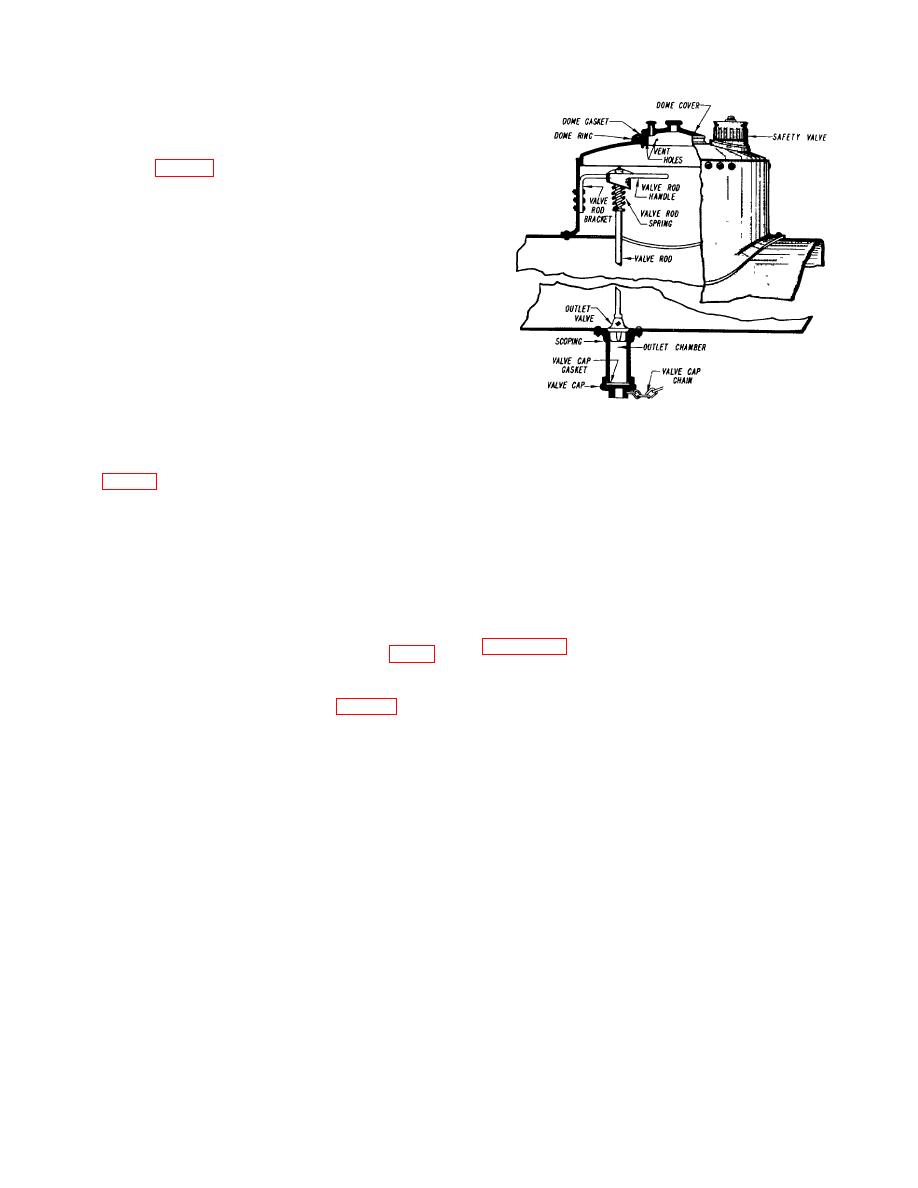

Figure 9-5. Arrangement of dome and, bottom

discharge outlet.

b. Dome. Most tank cars are equipped with

domes (fig 2-6). These are cylindrical chambers affixed

d.

Tank Cars in Theaters of Operations.

to the top of the tank to provide a means of filling the

Petroleum products are the principal commodities

tank to its full cubic capacity. Domes also serve as

moved in tank cars in oversea theaters of operations.

reservoirs for the accumulation of gases and fumes that

Tank cars of AAR, DOT, and CONUS specifications,

develop in the transportation of some liquids. The size

modified by emergency austerity demands, are standard

of the dome is governed by the size and class of the

for oversea theaters. The United States type center-sill

tank to which affixed. In multiple-compartment tanks,

construction between bolsters is incorporated in car

each compartment is equipped with a separate dome.

designs, and side buffing is provided for In designs

Domes are provided with vents or safety valves to

where hook-and-link couplers are used as shown in

exhaust accumulated gases or vapors. The details of

dome and outlet valve arrangement are shown in figure

applied to the bolster center-sill connection; this is

9-5.

preferable to the conventional European use of side sills

for buff resistance Standard bottom outlet valves and

dome safety valves are incorporated in tank car

installed on the underside of the tank and provide a

specifications, which are available from the US Army

means of emptying the contents of the car. They must

Mobility Equipment Command, St. Louis, Mo.

be constructed in such a manner that they will be

capable of passing the type of lading carried, whether it

9-34. Maintenance and Repair

be free-flowing liquid (aviation gasoline) or heavy

viscous materials (crude oil, molasses). The outlet

a. General. A leaky tank is one of the more

valve must be able to pass the contents without blocking

common defects encountered in tank car maintenance.

or stopping. It must also be made of materials which

The first and most vital tank car maintenance principle

resist corrosive action. Outlet valves extend downward

is: CAUTION-NEVER APPROACH A L,EAKING TANK

from the bottom of the tank to a point below the

CAR WITH AN OPEN LIGHT. This is applicable

underframe members, providing a ready access. These

whether or not the inspector knows what the lading

valves are opened and closed by a mechanism housed

consists of. In fact and in practice, an open light

in the valve and activated by a rod which passes from

(match, torch, candle, or lantern) must NEVER be used

the valve upward into and through the tank body, and is

in the inspection of tank cars, empty or loaded.

affixed to the inside of the dome housing.

9-14

Previous Page

Previous Page