TM 55-203

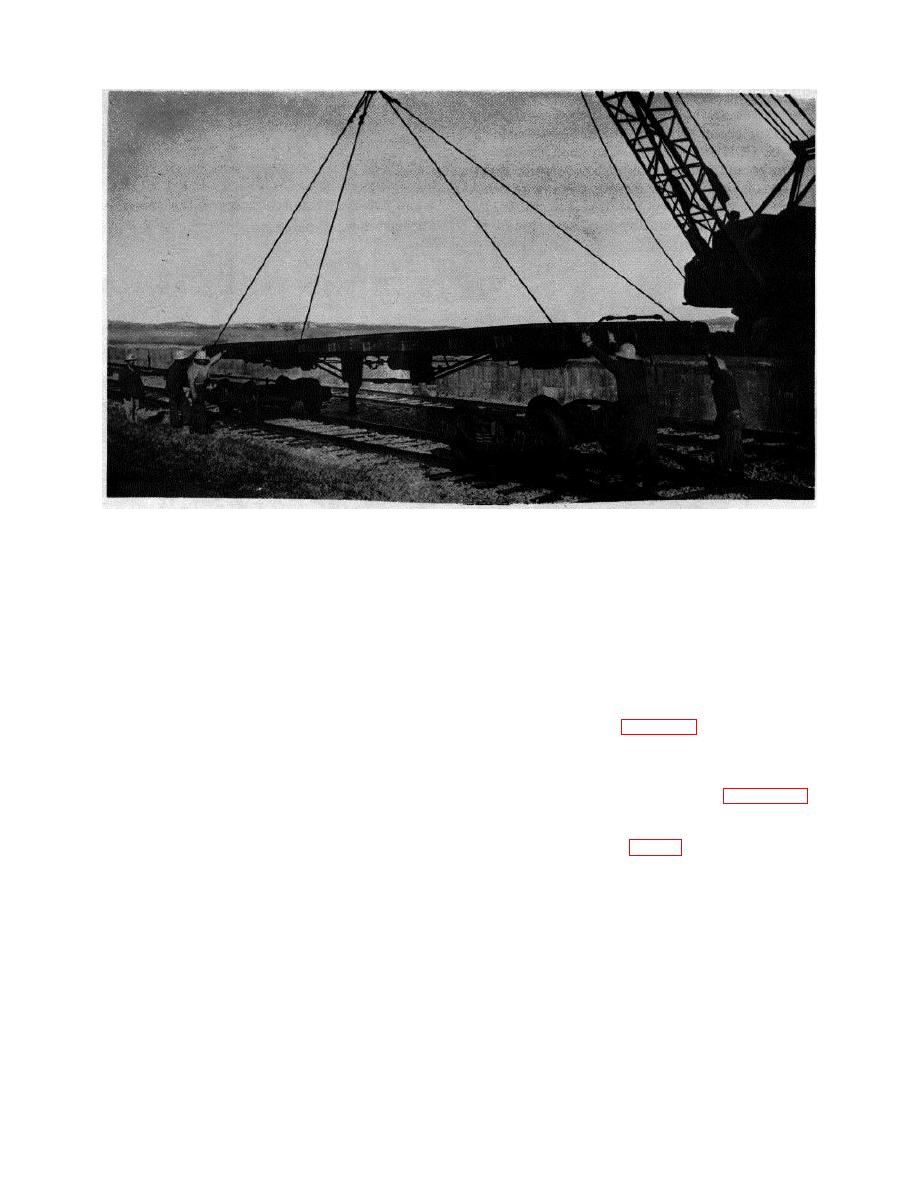

Figure 5-3. Lowering completed underframe on trucks.

Section III. REPAIR PROCEDURES

ease of handling. After careful measuring and planning,

5-7. General

the required template is constructed. The template is used

to mark for cutting the desired piece from a steel plate,

The usual procedures to be used in making typical repairs

beam, channel angle iron, or the kind of material

to car underframes and/or their components are

necessary for the repair. The template is also used for

discussed In the following paragraphs; only general

marking the new piece The piece is placed on firm, heavy

information is included. The nature and extent of the

planks supported with benches, horses, or some heavy

damage, the accessibility of the damaged parts,

base, as illustrated in figure 5-4. The template is clamped

preliminary disassembly or removal of components, and

In position on the piece, and holes and cuts are marked.

other factors determine the individual steps required for

After the template is secured, the piece is ready for

any particular repair job. Details are not discussed, but

cutting and drilling, followed by installation on the

the general procedures to be followed in repairing certain

underframe or other part of the car Figures 5-5 and 5-6

damaged parts or frame members are Indicated. Exact

show templates for angles and I-beam, respectively.

methods are based on the good judgment and experience

When it is necessary to make several duplicate parts,

of the carman.

stops on the templates (fig 5-5) save time and trouble.

b. Straightening Out-of-Square Underframes. When

5-8. Special Jobs

a car is sideswiped or receives a blow on a corner, the

whole underframe may be forced out of square. The end

a. Use of Templates. Special kinds of repairs may

and side sills may be bent so badly that they must be

require a special pattern of patch. After the method of

removed. They are later heated and straightened under

repair has been determined, a template of the patch

the press. The -center sill, body bolsters, crossties,

should be made. When a part is to be replaced by a new

diagonal braces and the remainder of the underframe can

one, a template insures that the new part will fit exactly

be left connected. Two chains are attached, one around

and that any necessary holes or cuts will be marked out

the end of each body bolster, and brought

correctly with a minimum of lifting and figuring.

Templates of skeleton construction, braced to retain

shape, are the easiest to make and to handle. A template

should

be

of

light

construction

for

5-4

Previous Page

Previous Page