TM 55-203

5-12. Body Bolster Fillers

a. General. Body bolster fillers are frequently

broken. Substantial repairs can be made with a patch

flanged on top and bottom to fit the place to be patched or

spliced. Such patches should extend at least 12 inches

on each side of the break. They should be secured by

rivets through the web on each side, staggered to fit the

condition. In CONUS, where AAR rules permit, the

patches can be welded When riveted, rivets securing the

top and bottom flanges of the patch to the flanges of the

bolster should be long enough to go through the top and

bottom cover plates. Usually, however, it is best to cut

out broken body bolster fillers and replace them. To

remove a pressed-steel flanged filler, the top and bottom

cover plate must be cut loose and the rivets which

connect the filler with the center sill and side sills must be

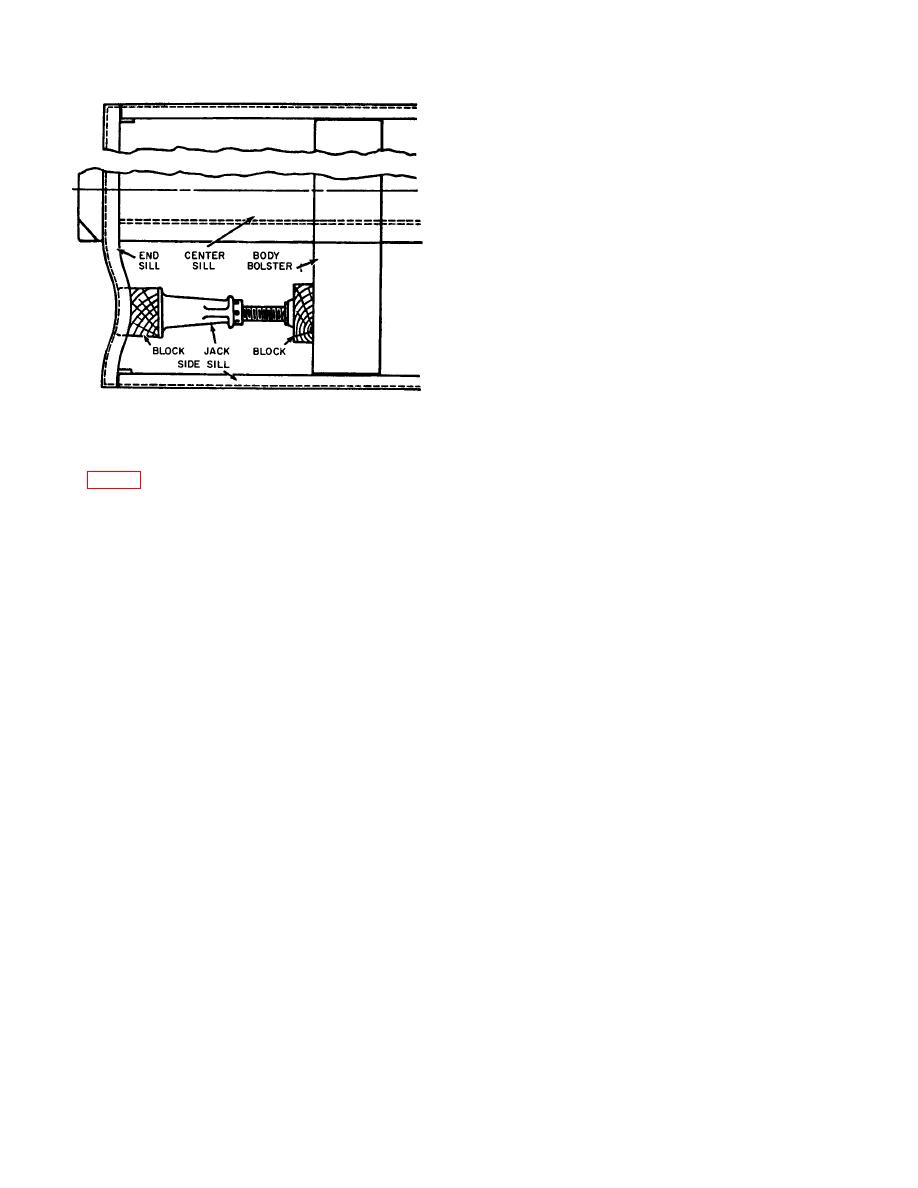

Figure 5-7 Straightening a pushed-in end sill by

cut The rivets which connect the adjacent crossbearer to

jacking against the body bolster.

the side sill must also be cut The side sill can then be

sprung out far enough to allow the old filler to be removed

and the new one fitted into place.

which connect each crossbearer to the center sill and side

sills (fig 5-1). If the angle irons, which connect the two

b. Body Bolster Center Plate. Broken body bolster

arms, are good they can be cut loose and used on the

new crossbearer.

In theaters of operations where

center plates must be renewed. The rivet heads are cut

acetylene is not available, rivets can be removed

off with an acetylene torch or a rivet buster and the old

manually by cutting the heads off with a chisel bar and

rivets punched out. Sometimes the center plate will have

sledge hammer, and knocking the old rivet body out by

to be pried down after the rivet heads are removed

use of a drift punch and hammer.

because the plate shanks are bent sideways to fit the

e. Stringer Supports. Defective stringer supports

small space between the lower bolster cover plate and the

center plate In this case, the rivet shank cannot be driven

usually are replaced They are removed in a manner

up and it will be necessary to burn off the rivet shank

similar to that described for renewing crossbearers.

below the center plate before the upper rivet head can be

removed. During riveting (or welding), the new plate can

5-10. Draft Castings

be held temporarily in place by two diagonally placed

bolts.

Draft castings are frequently found broken or missing.

Broken draft castings can be removed by taking out the

5-13. Straightening and Repairing Sills

draft gear, the coupler, and uncoupling level. The rivets

which hold the draft casting in place can be removed by

using acetylene torch equipped with a rivet-piercing tip. If

a. General. If a center or side sill is so badly broken

a rivet buster is available, the punch can be substituted

or damaged that repair is impractical, the sill must be cut

for the chisel and the old rivets backed out. When the

out completely, removed and replaced with a new one. It

rivets are removed, the draft casting can be easily

must be disconnected from the end sills, the body

lowered out. The new draft casting can then be riveted

bolsters, the diagonal braces, the crossbearers, and the

(or welded) in place.

stringer supports. When the new sill is installed, it must

be connected to all these same parts.

5-11. Cover Plates

b. Broken End Sills. When an end sill breaks, the

The center sill cover plate may be patched by cutting out

break usually occurs in the center. In this case, it is better

defective parts and replacing them with new ones. The

to cut the end sill off and replace it with a new one. The

new plate should be of the same thickness as the old

new end sill should be of heavier design that the original

cover plate and should be lapped about 6 inches at the

damaged

point of the old cover plate. Defective body bolster cover

plates should be removed, since they bear too, much

strain to make a patch practical.

5-6

Previous Page

Previous Page