TM 55-203

5-9. Steel Splices

a. General. Frequently, underframe sills are cracked

or broken through deterioration, rough handling, or

accident. In many cases the crack or break is of such

proportion or in such a location that the whole member

must be replaced. In other cases the sill may be repaired

by "splicing." Where practicable and especially in a

theater of operations, splicing of sills is recommended.

Splicing may be done on a sill adjacent to another splice

or adjacent to a sill that is spliced Whether the break is on

the inside, outside, or completely through, the procedures

will be generally as explained in b, below. In all cases of

splicing, reinforcing cover plates must be used on each

side of the broken sill, over the fracture.

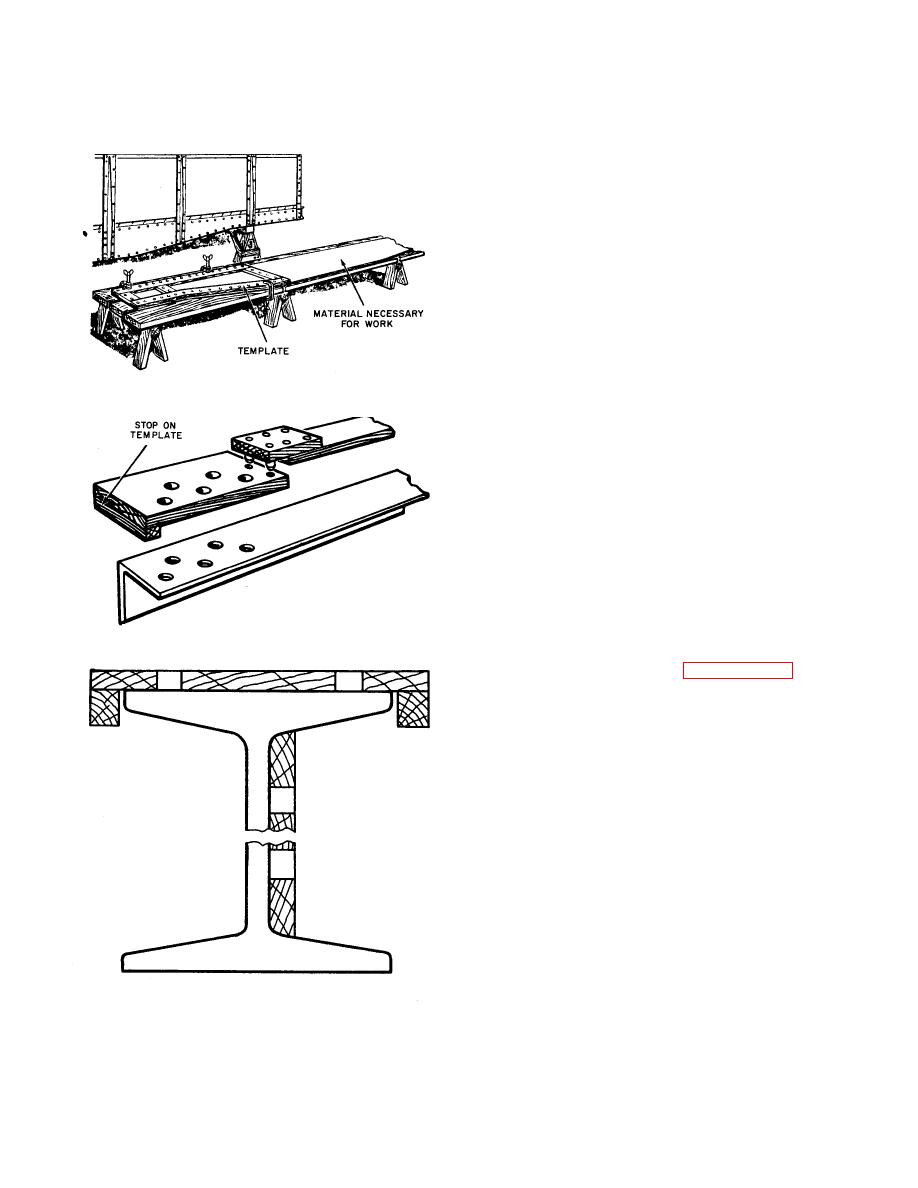

Figure 5-4. Marking with templates.

b. Center Sills. Before a broken sill is spliced,

measure the web and flanges A piece of steel plate as

thick as the sill to be spliced will be used in marking off

and cutting out the splice The location of rivet holes are

then marked off on the sill to be spliced Marking off may

be done by using a template as described in paragraph 5-

8a or by measuring and marking. After the splice plate is

put in place, the holes to be made are (marked for

punching or1 drilling Before any holes are made in the sill,

the adjacent broken parts of the sill must be drawn

together by bolts for butt-joint splicing These tie bolts hold

the sill until the splice is secured. In CONUS, AAR

regulations may require welding of the break before

Figure 5-5. Template for angle.

application of the splice cover plates As soon as the sill is

prepared, the cover plates are applied and riveted. The

riveting process is discussed in paragraph 5-19.

c. End and Side Sills. Because of the stresses land

strains to which the end sills are subjected, they are

frequently badly bent between the buffer and the corner of

the car. This damage may be repaired by placing a jack

against the bent part any applying heat to the sill with an

acetylene torch, at the same time tightening on the jack

as illustrated in figure 5-7. This usually will restore an end

sill to its original position. Side sills usually can be

straightened in a similar manner.

Small kinks in side and end sills may be straightened by

heating and hammering Broken side sills may be spliced

at any point between the end sills.

d. Crossbearers Defective Crossbearers usually are

cut out and replaced with new ones, since they connect to

the center and side sills. While it is a simple operation to

remove them, crossbearers may be patched if it can be

Figure 5-6. Templates for I-beam

done satisfactorily. Whether replaced or repaired, the

crossbearer must be removed by cutting the rivets

together In the middle of the frame with a pull jack. The

pull jack exerts a diagonal pull on the underframe,

bringing it back into square. Application of heat 'to the

center

sill

may

speed

the

operation.

5-5

Previous Page

Previous Page