Section III. Track Fastenings

3.19. GENERAL

One writer on rail subjects speaks of "the tie that binds." But something must bind that

crosstie to the rail. Several fixtures called track fastenings unite rail and tie.

When treated ties are used, wood decay is practically non-existent and therefore is

seldom the reason for tie renewal. More often, mechanical wear is the cause, that brought on by

rails, spikes, and ballast under the impact of a moving train. Tie-protecting devices (tie armor)

have been developed to minimize tie damage. These devices are usually referred to as tie plates.

Other track fastenings--spikes, rail anchors, braces, and gage rods--make their contribution to

efficient track.

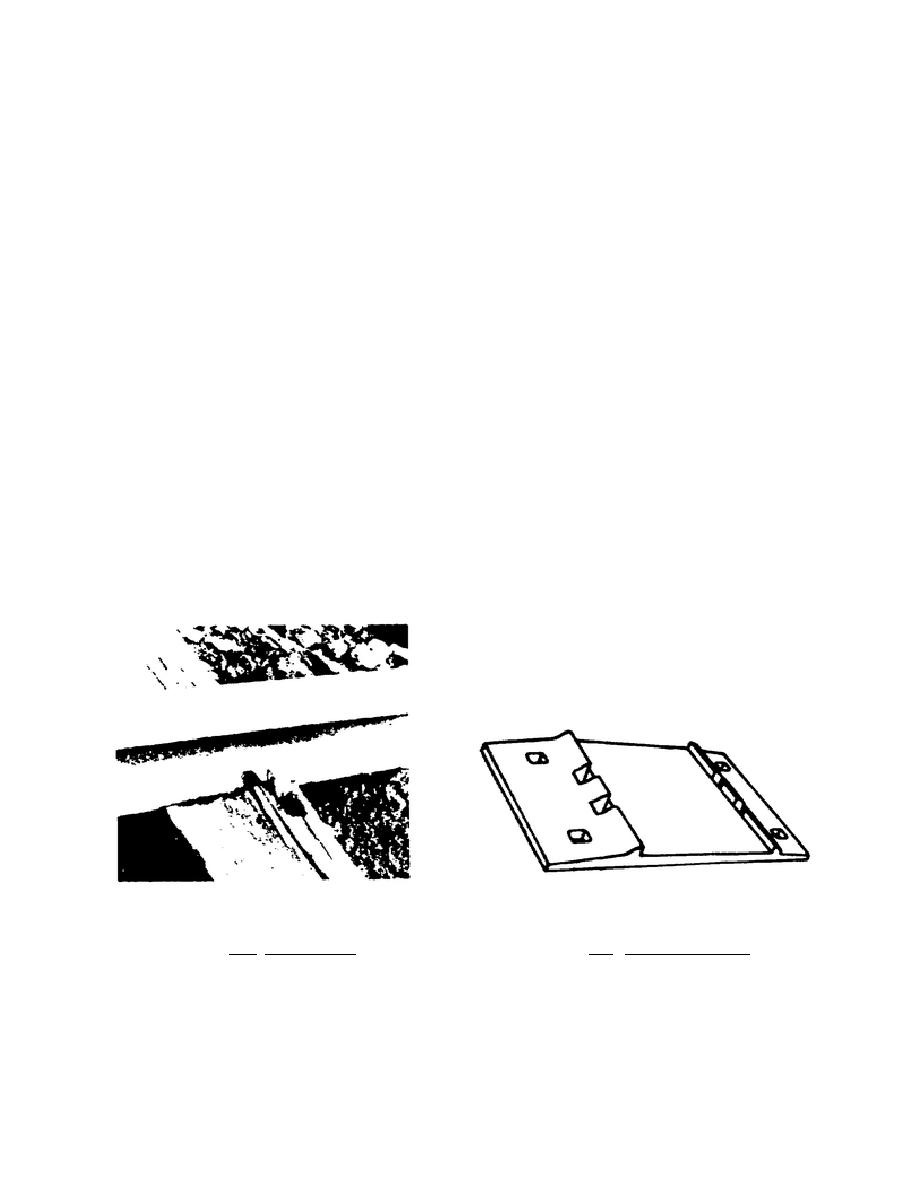

3.20. TIE PLATES

Tie plates serve as seats under the rail, between the rail and crossties. The plate spreads

train weight over a wider area of the tie than does the base of the rail and reduces tie wear

resulting from abrasion or crushing of the tie by the rail. Figure 3.7 shows the effects of wear on

a tie not protected by a tie plate.

Tie plates are made of steel. They have square holes punched in them to receive spikes

and have an indented, flat surface on the upper side to fit the base of the type of rail for which

they are designed to be used. Figure 3.8 shows the details of a typical tie plate. Tie plates are

seldom used on tangent track in a theater of

operations. Two per tie should be used if they are

available.

They are used on temporary

construction for turnouts,

Figure 3.7. Rail-Cut Tie.

Figure 3.8. Typical Tie Plate.

57

Previous Page

Previous Page