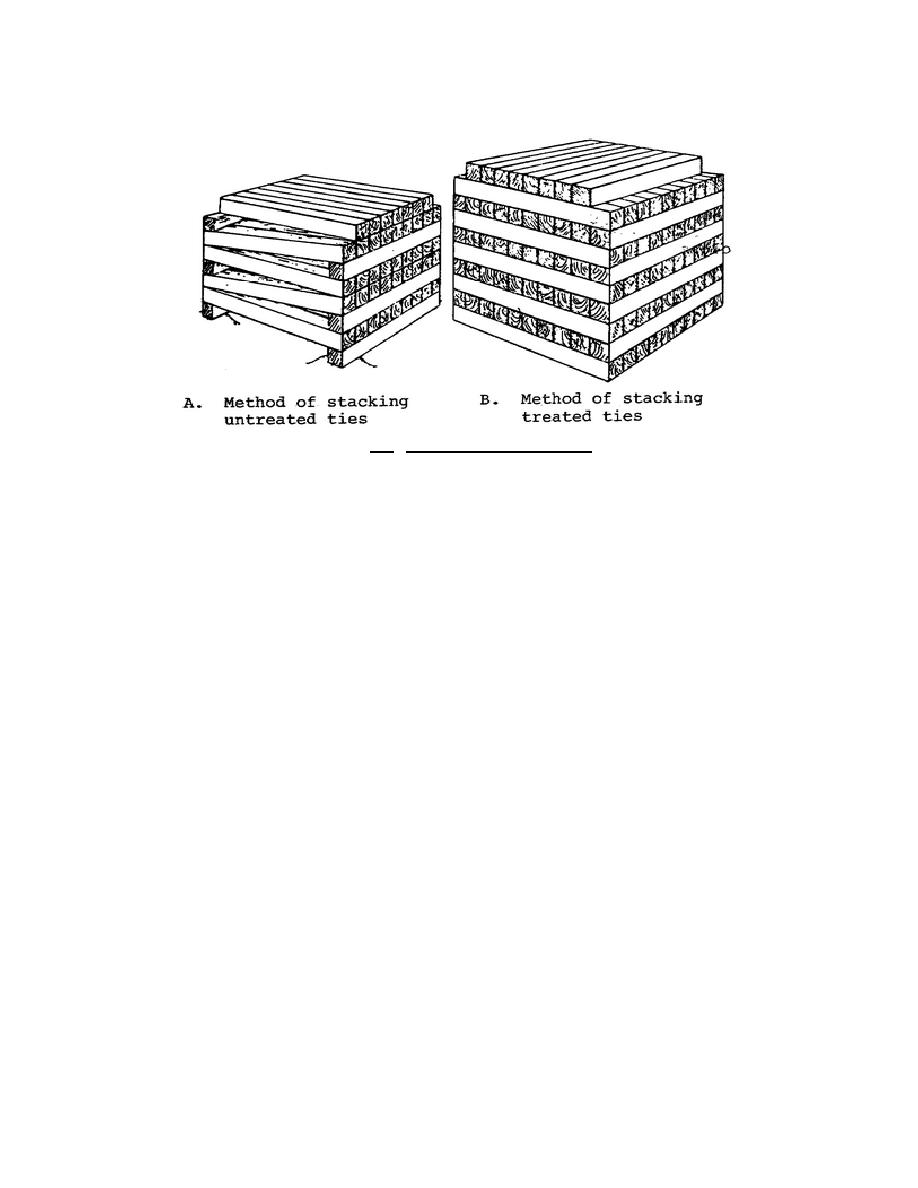

Figure 3.6. Methods of Stacking Ties.

Decay is deterred by placing the heart face down. As the tie weathers, the heart face shrinks and

become concave. Checks tend to hold moisture, the cause of most decay, and more moisture

would be held by the checks if the concave surface was on top.

3.18. SUMMARY

Crossties may be made of concrete or steel but are usually made of wood, or cheap

resilient material and one that allows the use of driven spikes to hold the rails. Both hardwoods

and softwoods are used. Ideal ties are straight but may be curved slightly as long as a straight

line drawn from one end to the other does not leave the edge of the tie. In the United States,

standard ties are 8' to 9' long and are placed 10 to 18 inches apart. For commercial use, wooden

ties are preserved by creosote or zinc chloride. Ties used in a theater of operations are not

permanent enough to warrant such treatment. Adzing and boring are done before the chemical is

applied. Drive antisplitting irons into the ends of ties to prevent checking. Always place the

heartwood side of the tree on the ballast. Stacking ties properly help prevent rotting and oil

56

Previous Page

Previous Page