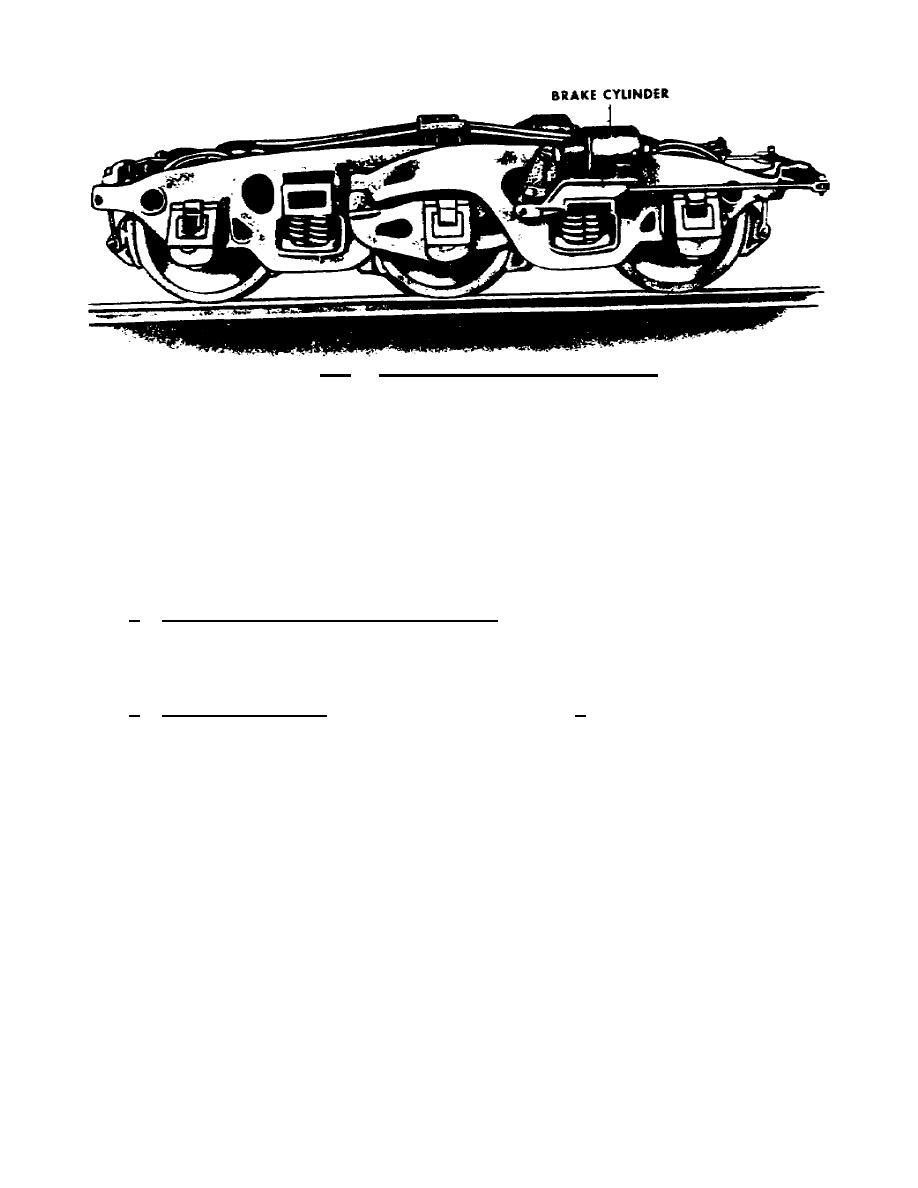

Figure 3.8. TruckMounted Brake Cylinder.

journal, cut off lubrication in the area, and cause the journal to overheat.

Normally, friction heat is transferred to the bearing, the wedge, the

journal box, and the atmosphere. But when there is a waste grab, the heat

increase is greater than the heat transfer, and a hotbox results. When this

happens, the lubricant and packing ignite and the overheating increases.

Excessive overheating of the journal changes the composition of the metal

and causes the journal to break and the car to derail. If scratches are

visible on the journal, the wedge and bearing should be removed and a check

made for waste grabs. If waste is present between the bearing and journal,

it should be removed.

b. Waste packing or lubricator pad. The journal and bearing are

supplied lubricant by waste packing or a lubricator pad. The location is

labeled in figure 3.3. When kept properly lubricated, the packing prevents

waste grabs from becoming lodged between the journal and the bearing.

c. Brass and wedge. As subparagraph 3.4e(4) states, the journal

friction bearing is made of brass with a babbitt metal lining. It is often

referred to in railroad terminology as "the brass. " When the journal box

lid is opened, the ends of the bearing and wedge can be inspected. No

breaks or cracks should be visible on either the bearing or the wedge, and

they should be properly positioned at the

50

Previous Page

Previous Page