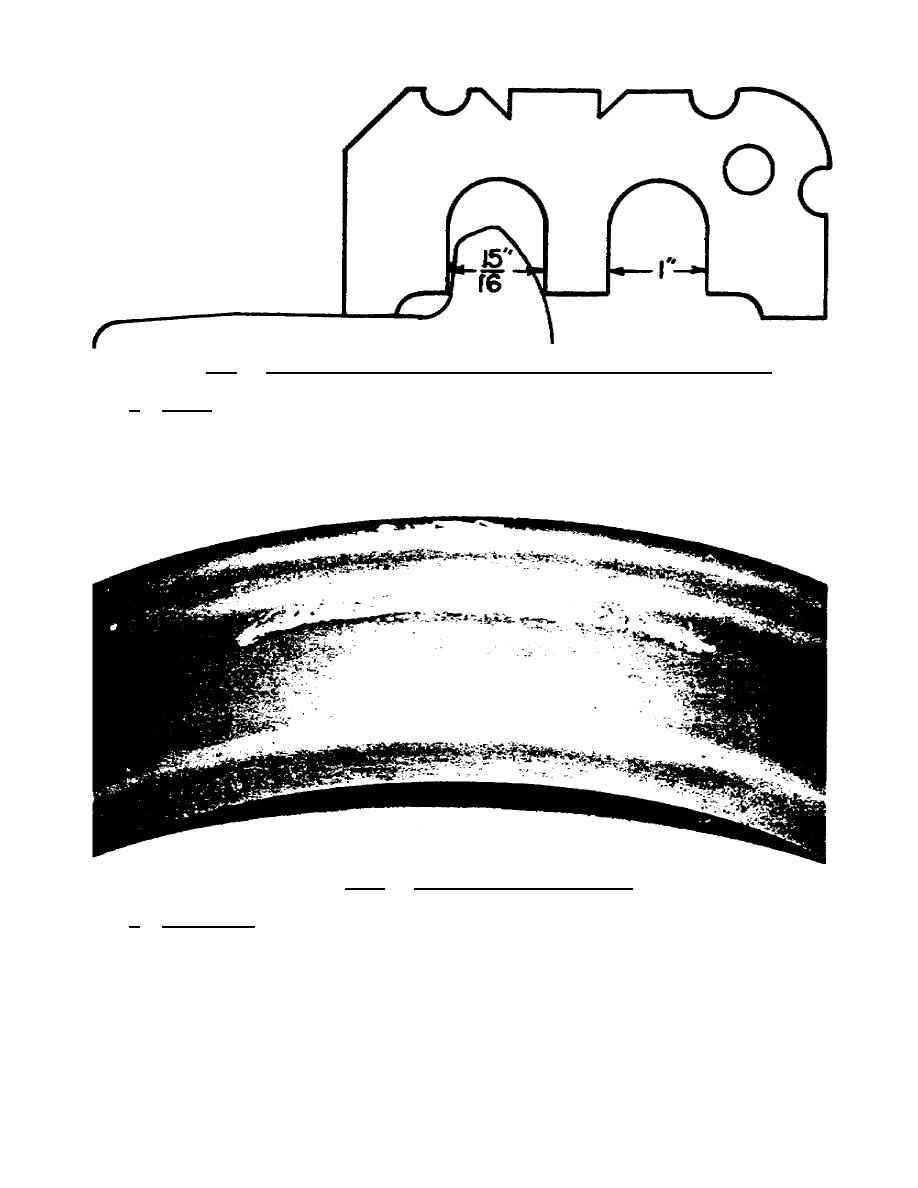

Figure 3.9. Wheel Having Thin Flange Defects With Gage in Place.

b. Seams. One of the most serious wheel defects is a seam or

lengthwise crack in the tread. When a seam is located close to the flange,

it can cause the flange to break off the wheel. If a seam is detected

within 3 3/4 inches of the flange, the wheel must be removed. Figure 3.10

shows a wheel with a seam within the condemnable limit.

Figure 3.10. Wheel With Seam Defect.

c. Slid flat. A violent application of the brakes locks the wheels

causing them to skid along the rails. Such skidding results in worn flat

spots on the wheel treads called slid flat spots. If a wheel tread has a

slid flat area 2 1/2 inches or more in length, the wheel must be replaced.

If the wheel has two or more adjoining slid flat spots each 2 inches or more

in length, the wheel is condemnable. Passenger car wheels must not have

slid flat spots in excess of

52

Previous Page

Previous Page