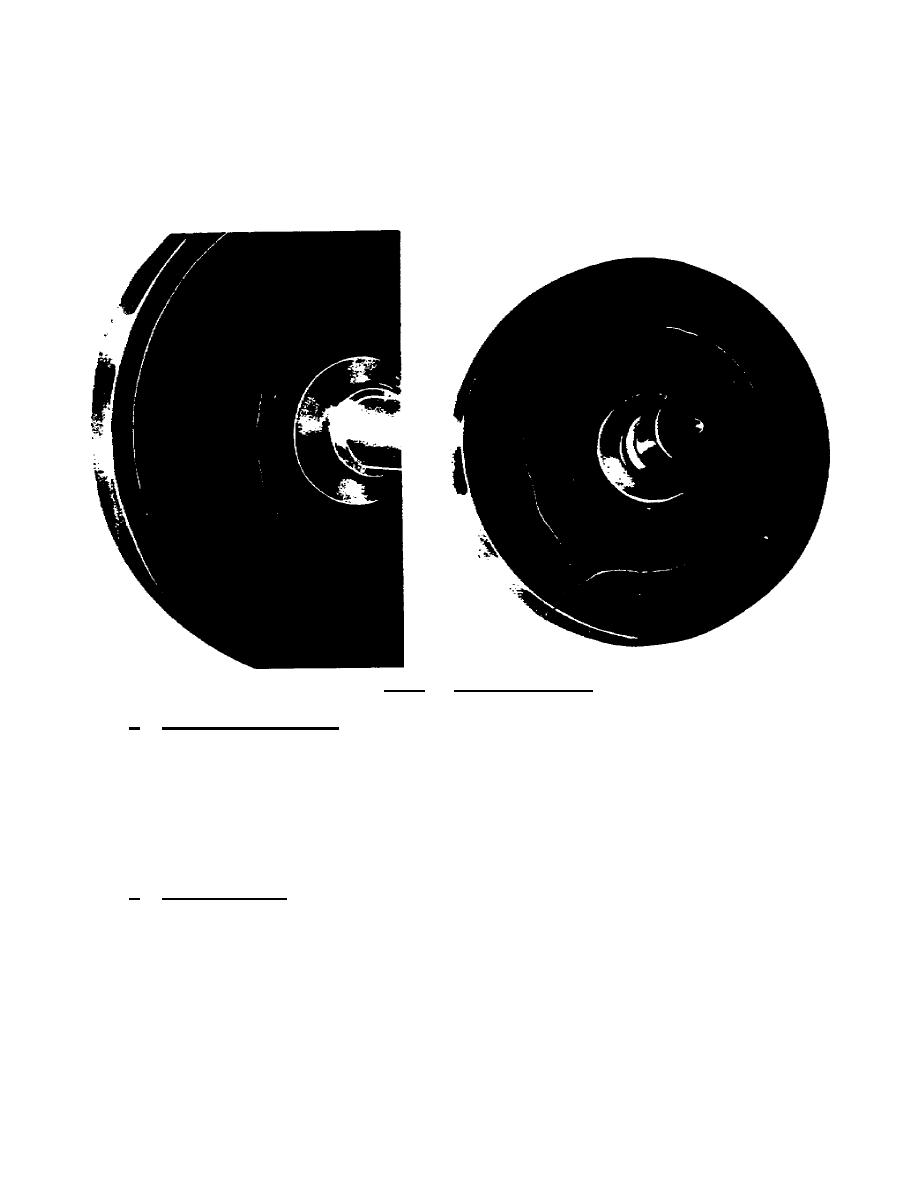

3inch crack in the plate can grow into a socalled "cupid's bow" crack, as

part A of figure 3.14 shows. Its name is derived from the bowlike shape the

crack assumes when the two ends turn outward toward the rim. A cracked

plate is easily detected by a careful inspection of the wheels. However, if

such a crack is neglected, it can extend through the rim, as part B of

figure 3.14 shows, and cause the wheel to fail.

Figure 3.14. Cracked Plates.

f. Tread worn hollow. A gage is provided for condemning wheels for

worn hollow treads, as shown in figure 3.15. When the two ends of the gage

touch the rim and the flange but the bottom nipple on the gage does not

touch the tread, the wheel has reached the condemnable limit and must be

removed from service. The real limit of a tread worn hollow defect is the

height of the flange and this is what the gage is based on. Wheels should

not be condemned for having treads worn hollow before the gage limit is

actually reached.

g. Out of round. If a wheel has a worn spot in the tread more than

3/64inch deep, it is out of round and has reached the condemnable limit. A

wheel with this defect causes damage to the track, equipment, and lading

when the train is traveling at high speeds. Figure 3.16 shows the gage

applied to a defective 33inch wheel.

54

Previous Page

Previous Page