TM 55-203

Outlet hose must be 3/4-inch diameter with 1/2inch

of the control of the flow of brake pipe air through the

connecting nipples and must not be more than 8 feet

choke to the brake cylinder. Some equipment has been

long.

manufactured without the choke plug but with the

auxiliary reservoir tapped for insertion of the plug later,

(4) In the event of valve falling to pass the

if desired. Consequently, on such equipment, the quick

specified test, it should be ascertained that the single-

action feature (para 8-20b) is operative.

car testing device is not at fault. If the device is not at

fault, airbrakes must be cleaned.

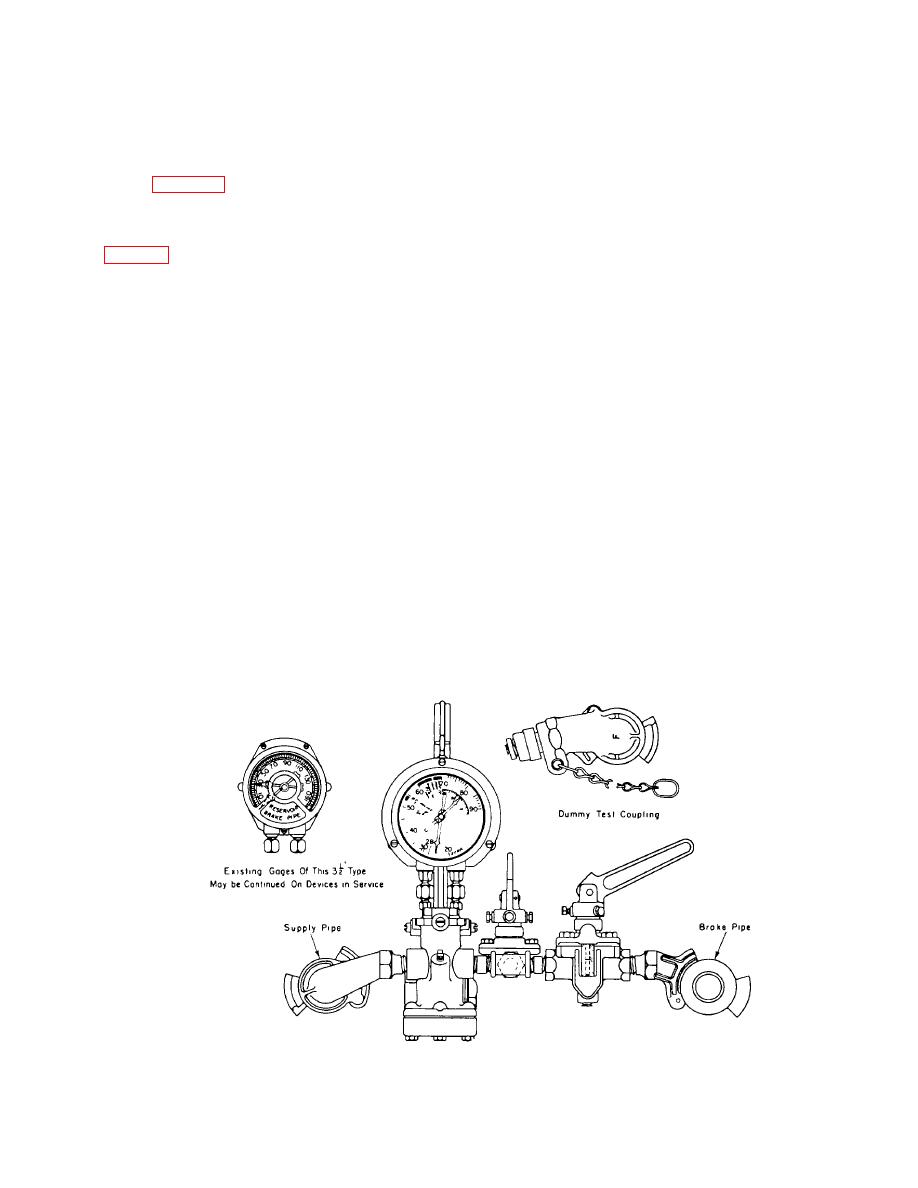

8-28. Single-Car Testing Device

a Operation. The purpose of the single-car testing

(5) Care should be exercised in moving the

device (fig 8-51) is to provide a means for a general

test device handle back to position No. 3 (lap) after

check on the condition of the brake equipment on "in-

making brake pipe reductions of 15 pounds or more in

date" cars while in service and on cars which have

position No. 5 When snapped back, the temperature

undergone periodic repairs without the removal of any

effect will cause the brake pipe pressure to rise 1 1/2 to

device from the car.

2 pounds and may be the cause of an undesired

release. The device handle should be moved slowly

(1) There are two types of single-car testing

toward lap position.

devices which are similar in appearance. One is for

passenger cars and the other for freight cars. The

(6) When making tests of cars having two

passenger device can be identified by a nameplate

sets of brake equipment, each set must be tested

marked PASS, while the freight device is marked FRT.

separately, with the branch pipe cutout cock closed to

Freight device is now equipped with a flowrator to check

one set while the other set is being tested. A complete

flow of air through device.

test (including brake pipe leakage on passenger cars)

must, however, be made with each set of equipment

(2) The single-car testing device arrangement

unless the passenger single-car testing device with

must include a suitable feed valve or reducing valve in

flowrator is used. If both sets are connected to use one

the supply line for the purpose of providing a constant

common brake cylinder release valve, it will also be

pressure source as defined in the test codes and an

necessary to blank off the 3/4-inch brake cylinder pipes

efficient air filter in the supply line ahead of the feed

at both the control valve and the brake cylinder on the

valve.

set not being tested. This may readily be done by

temporarily inserting 1/16 by 1 7/8-inch blanking plates

(3) The use of a hose is optional between the

between the flanged fittings and the bolting faces.

testing device and the outlet hose coupling which

connects to the brake pipe hose on the car.

Figure 8-51. Freight single-car testing device with flowrator.

8-57

Previous Page

Previous Page