TM 55-203

(c) When a new ring is to be fitted, place

ring in the body cylinder; a snug fit should be obtained.

Check alignment of piston and position outside surface

of ring into ring groove. Turn the ring the full length of

the circumference and note if ring is restricted from

turning freely. If ring does not turn free, remove burrs or

repair as required. Position ring in groove. A slight drag

should be felt when, turning the ring in the groove.

Note. When fitting new lap joint rings, they

must be carefully installed with the narrow bearing

surface of the scarf towards the brake pipe side.

(d) If the wick which runs from the small

crescent-shaped recess in the bottom of the ring groove

to the oil reservoir is damaged, it must be replaced. A

new wick is approximately 5 3/4 inches long. To

facilitate assembly, a special wick is available having

bare wire on one end for about 2 1/4 inches. If specially

prepared wicks are not available, bare the wire by

burning. Start the wire down through the wick hole and

pull the wick through the hole until about 1/2 inch end is

left in the ring groove. Bend the end of the wick across

the middle or breather hole and anchor in the last hole in

the recessed ,section at the bottom of the ring groove.

Cut the bare wire off the wick and wind it in a

counterclockwise direction around the oil reservoir. The

free end of the wick must not obstruct or come in

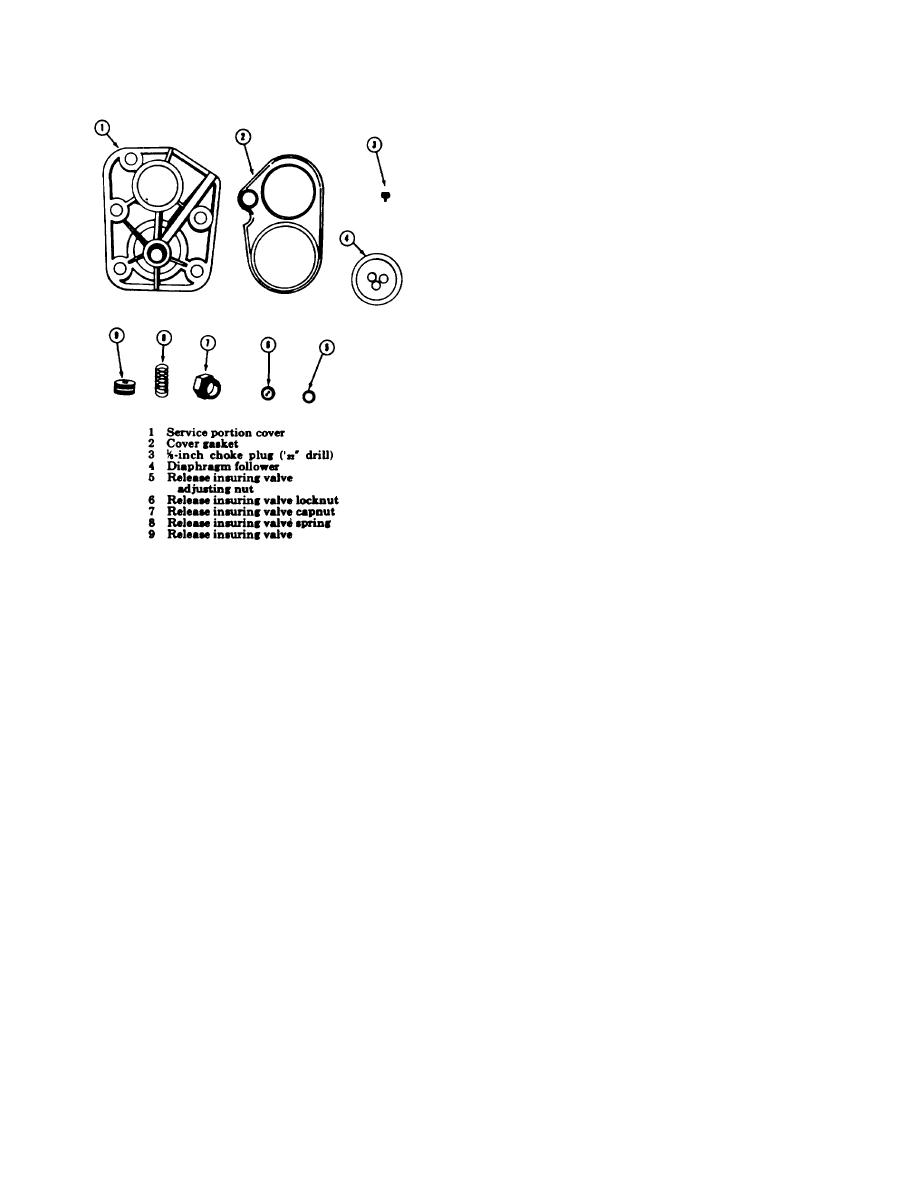

Figure 8-21. Service portion cover and release

contact with the 1/32-inch-diameter breather hole

insuring parts.

located adjacent to the wick hole in the oil reservoir.

(c) Thoroughly clean all parts with an

(e) When the piston ring and its groove are

organic solvent type cleaner to remove all dirt, oil, gum,

thoroughly clean and dry, position the end of the ring

and grease. Do not use an alkaline cleaning solution.

above the lubricating hole in the bottom of the ring

Lubricate the entire surface with one drop of lubricating

groove. Raise the end of the ring and make sure that

oil (SAE-20).

the lubricating wick is flat on the bottom of the recessed

(6) Inspection and lubrication of self-oiling

portion of the ring groove. The wick must not touch the

piston

ring or the mouth of the breather hole.

(a) Clean the piston ring and its groove by

dipping the piston in cleaning fluid and then moving the

(f) Remove the oil plug which seals the oil

ring around in the groove. Repeat the operation until

reservoir and drain the old oil from the reservoir. If the

the groove and ring are thoroughly cleaned.

oil plug is of the hexagon type, insert a capscrew into

the outer tapped opening so it will not be distorted with

Note. An early type of self-oiling piston,

the wrench when being removed. Use care to avoid

having two holes drilled in the piston head near the top

twisting the piston stem. If the oil plug has been

of the piston, must not be submerged in cleaning fluid.

tightened excessively, tap lightly or use some other

For this type of piston, see instructions in (7) below.

means in loosening it rather than by means of a wrench

and vise, which will cause damage.

(b) Where rings are stuck with dirt too

tightly to be moved in the groove, soak the ring in

penetrating oil and then tap the ring gently with a

hardwood block to drive it flush with the top edge of the

groove. Start the tapping at one side of the ring joint

and progress around the piston in short steps until the

ring is loosened sufficiently to be moved in the groove.

If this procedure will not loosen the ring, it is evident that

the groove is binding and must be reconditioned and a

new ring fitted.

8-24

Previous Page

Previous Page