is placed between the wheel and the cleat to prevent chafing the tire. The

material is put under the bottom cleat and extended 2 inches above the top

one.

c. Vertical force. A load is subject to vertical force, or bouncing,

to a degree depending upon the roughness of the roadbed. To keep this

bouncing motion to a minimum, wire is used to tie the truck down to the side

stake pockets. To do so, four strands of No. 8gage black annealed wire, or

wire of equivalent strength, are twisted into cables (two cables per wheel),

then run through holes in the vehicle wheel, and finally secured to the

stake pockets. Note item G in figure 2.4.

Other tiedowns are also used to hold down the bouncing motion; note

item E in figure 2.4. They may be located over the axle, spring, or spring

shackles. The tiedowns consist of 1inch 14gage black annealed wire and

pattern 19 anchor plates secured to the floor with eight twentypenny cement

coated nails.

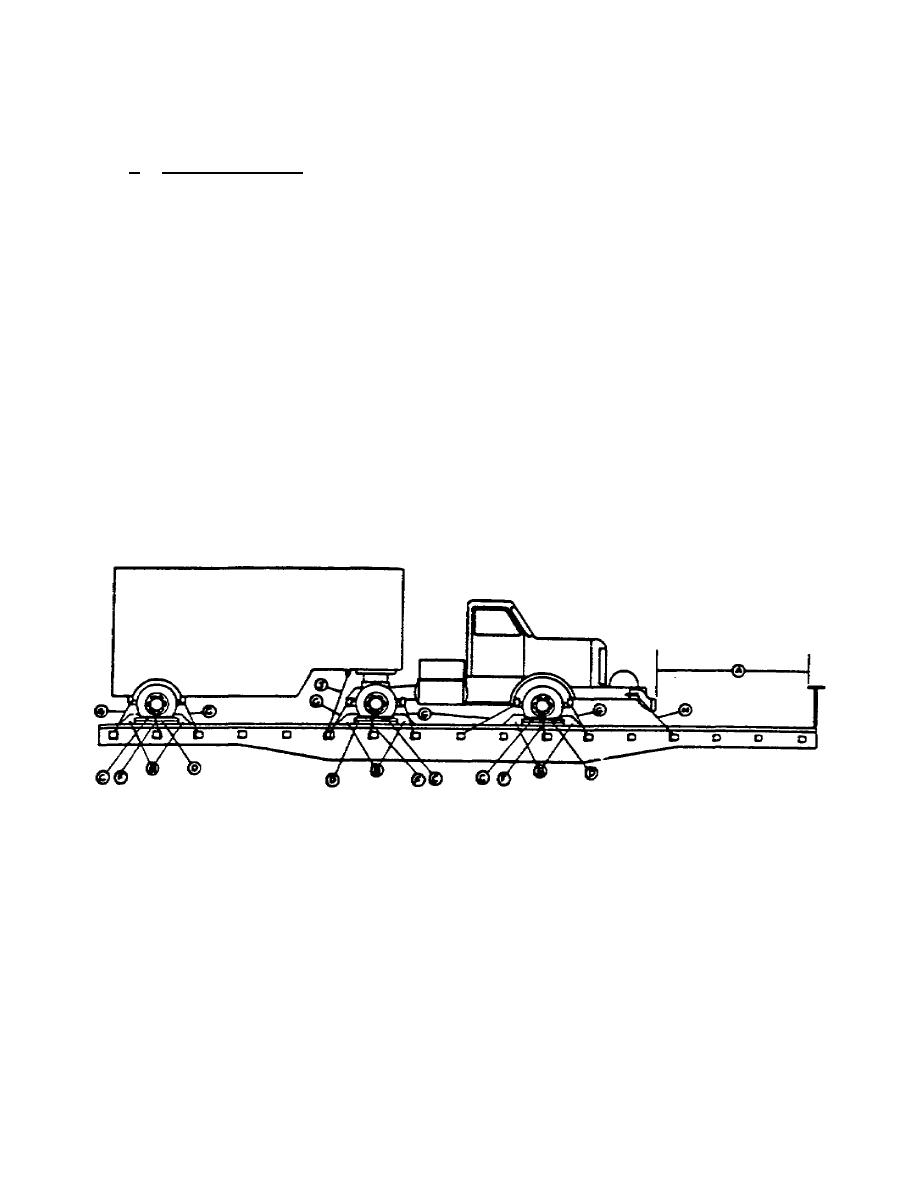

2.5. TRUCK TRACTORSEMITRAILER

Blocking and bracing a lightweight semitrailer with its truck tractor

on a flatcar is not as complicated as you might expect. In fact, you are

already familiar with most of the requirements. To prove this to yourself,

look over the sketch inserted here and try to identify the lettered items.

The space labeled A, of course, refers to brake wheel clearance. Here the

distance exceeds the normal requirement of 12 inches between brake wheel and

load. Since the truck tractorsemitrailer is the total payload on this car,

centering the vehicle's heaviest point in the middle of the car necessarily

moved the truck farther back. The items labeled B, although you can't be

sure from the sketch, are pattern 16 blocks. Other patterns are required

for blocking other kinds of vehicles. The waterproof paper is labeled C;

this is applied after blocks are in place and before

34

Previous Page

Previous Page