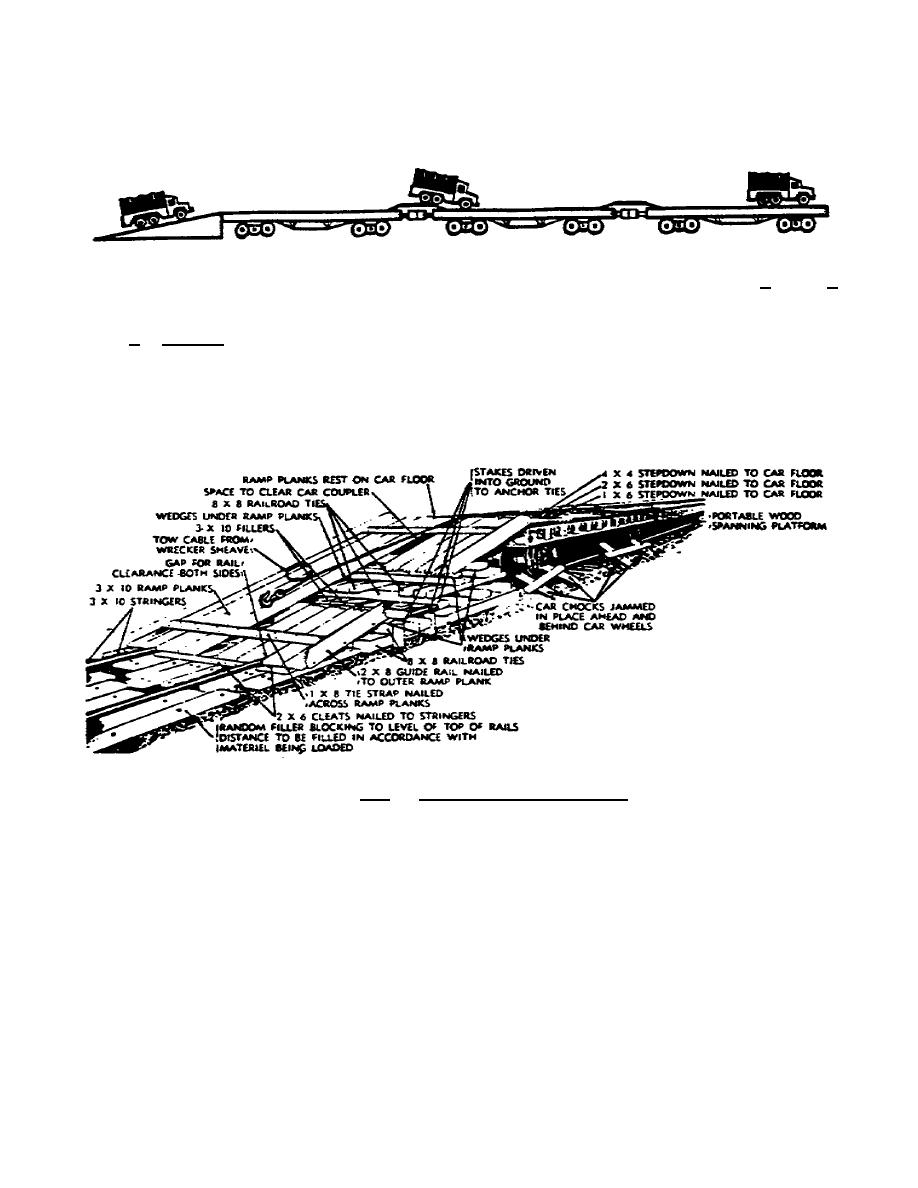

driven up the ramp onto the rear car and moved forward across spanners to

the car on which it is to be shipped. This socalled circus method,

pictured in the sketch, is the quickest and most common way of loading

vehicles. What, exactly, are ramps and spanners? Subparagraphs a and b

explain both of these loading aids.

a. A ramp must be constructed or improvised if none is on hand, and a

stretch of the roadbed leveled so that equipment can be maneuvered onto the

ramp. The roadbed can be raised to the top of the rails by using 6 by 8

inch timbers or dirt and cinders. Although construction of the ramp will

vary with the required capacity, figure 2.1 shows a ramp that will support

most vehicles.

Figure 2.1. Vehicle Loading Ramp.

As a field expedient, a ramp may be improvised by using the last

flatcar itself as a ramp. Without going into the details of how this is

done, essentially what happens is that the end truck is temporarily detached

from the flatcar body and the body lowered onto a supporting wooden block.

With one end of the flatcar deck close to the ground, only a few timbers are

needed to form a runway, as shown in the two views in figure 2.2. Ramps

should be carried with the shipment if no unloading facilities will be on

hand at the destination. When the ramps are shipped, their weight must be

figured as part of the weight of the load.

30

Previous Page

Previous Page