Chapter 2

PRINCIPLES AND PROCEDURES

2.1. INTRODUCTION

Military equipment is constantly moving by railsome headed for

maneuvers; some on its way overseas; and some traveling to new posts,

depots, or maintenance facilities. And somebody had to load it. Because

you may be that somebody someday, you should find it profitable to learn

exactly how such equipment is loaded: what size nails are used, where cable

is attached, and so on. Chapter 1 discusses the fundamentals of rail

shipments: the physical equipment and the rules for using it. Now chapter 2

shows how that equipment is put to use, observing those rules, in the

shipment of some typical Army items. Whereas chapter 1 illustrates the

loading of a 5ton truck to show what could be found in a particular

publication, chapter 2 takes a closer look at the loading process and the

blocking and bracing materials themselves. Section I takes up principles

and procedures; section II applies those principles aid procedures to

specific loading problems.

Section I. Loading, Blocking, and Bracing of Military Equipment

2.2. GENERAL

As valuable as "learning by doing" may be under some circumstances, in

loading military equipment it can be both time consuming and dangerous. For

this reason, the Army spells out precisely how a particular item will be

loaded, blocked, and braced on rail cars. This section discusses ramps and

spanners used in getting vehicles onto the car, techniques employed in

loading, and materials used in blocking and bracing selected items.

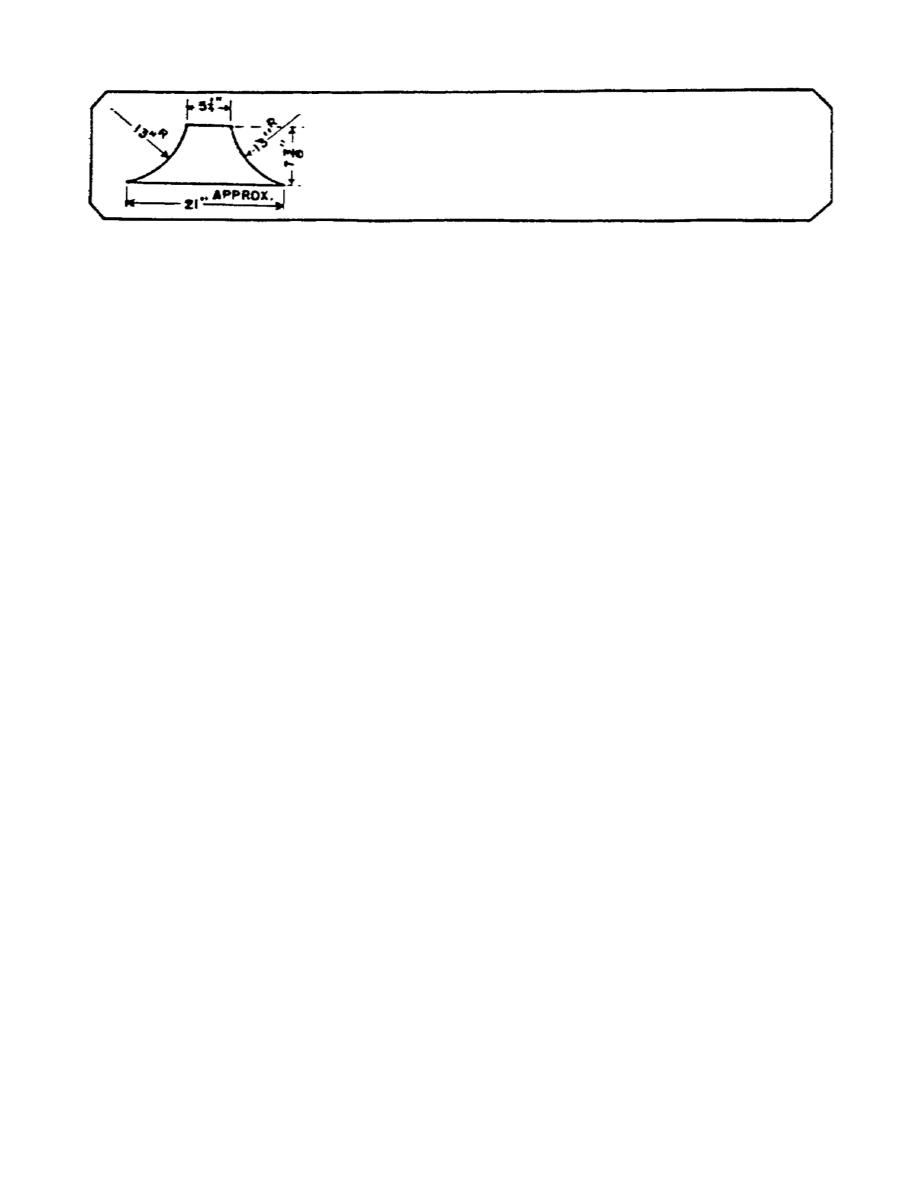

2.3. RAMPS AND SPANNERS

Have you ever wondered how trucks get from the ground onto flatcars?

Although several means can be used, the customary method is to drive

vehicles up a ramp to the desired position on the car. When several

vehicles are being loaded onto more than one car, spanners are used to

bridge the distance between the cars, making one continuous roadbed of the

train. In this way, each vehicle is

29

Previous Page

Previous Page