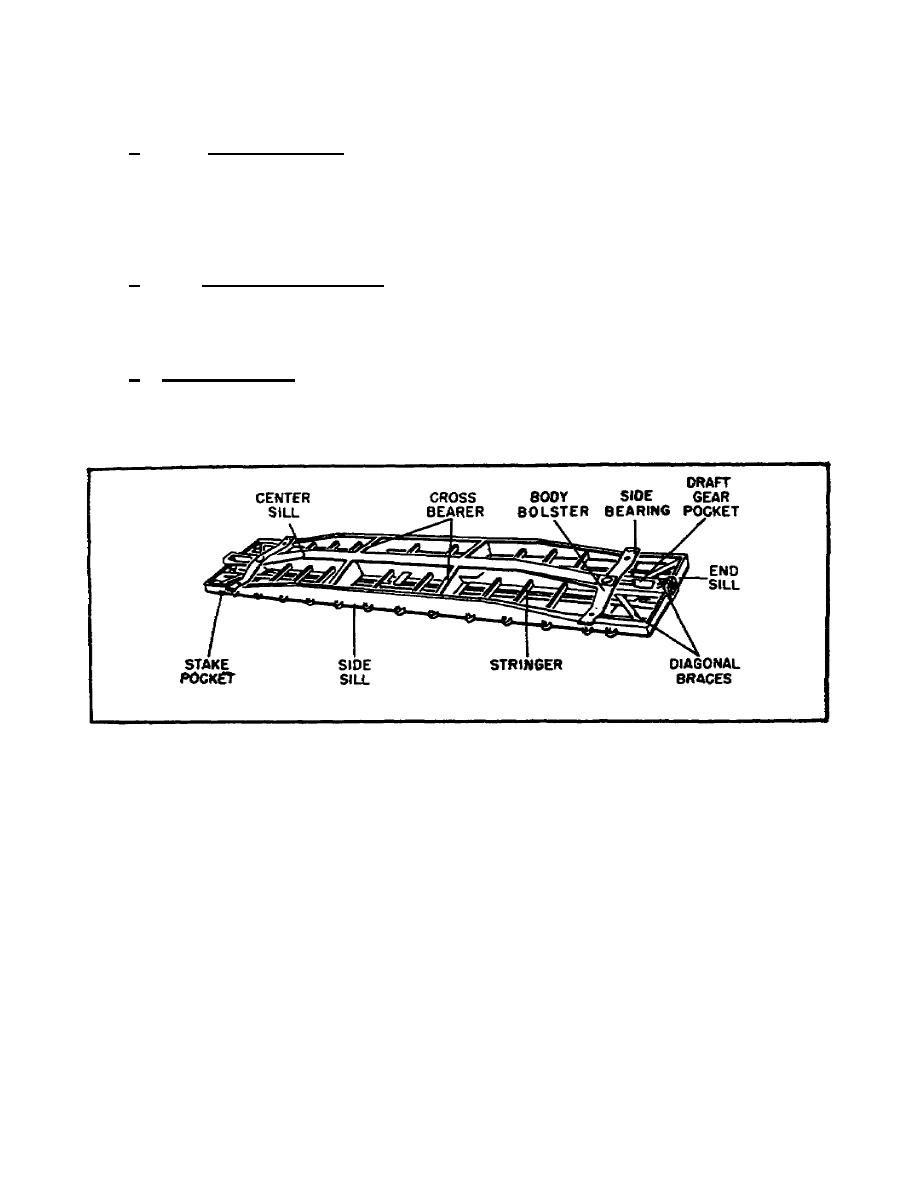

throughout the length of the car. It contains the couplers and draft gears

in pockets at either end.

b. The body bolsters are transverse members of the car underframe

located over the center of the trucks. Resting on the truck bolsters, they

transmit the weight carried by the center sill to the trucks through the

mated body bolster and truck bolster center plates. The body bolsters

contain side bearings that steady the car and prevent excessive rocking

while it is in motion.

c. The draft gear pockets are the receptacles located at either end of

the center sill that receive the draft gear and couplers. The striking

plates or castings are part of the coupler and draft gear arrangement. The

draft gear is discussed further in paragraph 3.6.

d. Other members required to complete the underframe are side sills,

end sills,. and floor stringers. They provide the tremendous strength

necessary for railway car operation and the mounts for the decking that

carries the load. These members are identified in the inserted sketch.

3.4. TRUCK ASSEMBLY

The wheeled assemblies at each end of the car are called trucks. Each

may have one, two, or more pairs of wheels. Most freight equipment in the

United States has 4wheel trucks. Railway cars and dieselelectric

locomotives use the same type of truck assemblies, discussed in paragraph

2.7. The trucks support the underframe and superstructure; they swivel

enough to ride the rails and negotiate curves readily. An important feature

of these assemblies is that the essential parts most likely to require

repair or replacement are easily reached. A typical freight car truck is

shown in figure 3.2. Study it as you read the following subparagraphs in

which some of the assembly's parts are discussed.

40

Previous Page

Previous Page