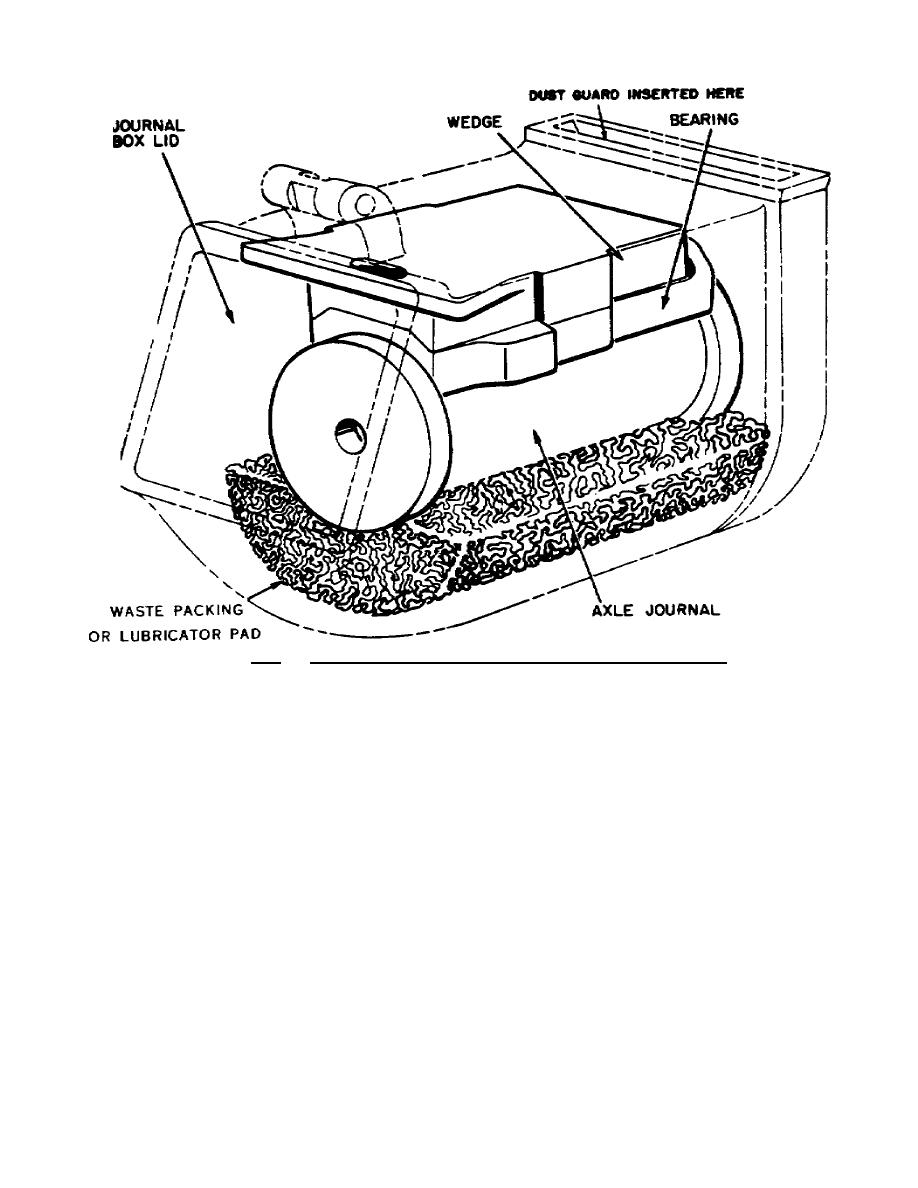

Figure 3.3. Journal Box Assembly With Friction Bearing.

(1) Journalend of the axle, or the part of an axle on which the

journal bearing rests.

(2) Waste packingcushioning made of fibrous material placed in the

bottom of the journal box. Saturated with a lubricant, the packing feeds

the lubricant to the journal and bearing. A commercial springtype

lubricator pad has been substituted for waste packing on most U.S.

commercial railroads.

(3) Wedgeholds the bearing in place and distributes weight from the

side frame to the journals, through the wheels, to the rails.

(4) Bearingdevice that provides a smooth working surface against

the journal. The friction bearing is a brass casting with a babbitt lining.

It transfers friction heat to the top of the journal box through which it

escapes to the atmosphere by the passage of cool air over the journal box.

43

Previous Page

Previous Page