or more and flat spots 1 inch or longer condemn the wheel. Figure 2.8 illustrates the combination tread defects

and the proper measurements.

h. Tread-worn-hollow (Rule 76--AAR symbol

76). The tread-worn-hollow gage shown in figure

2.3 is used to measure the extent of hollow wear.

The figure also shows the proper application of the

gage to the wheel. If the nipple at the bottom center

of the gage does not touch the tread when the front

and rear bottoms are touching the top of the flange

and the top outside of the rim respectively, the

Figure 2.8.

Measurements

for

Combination

wheel is worn beyond the condemning limits.

Tread Defects.

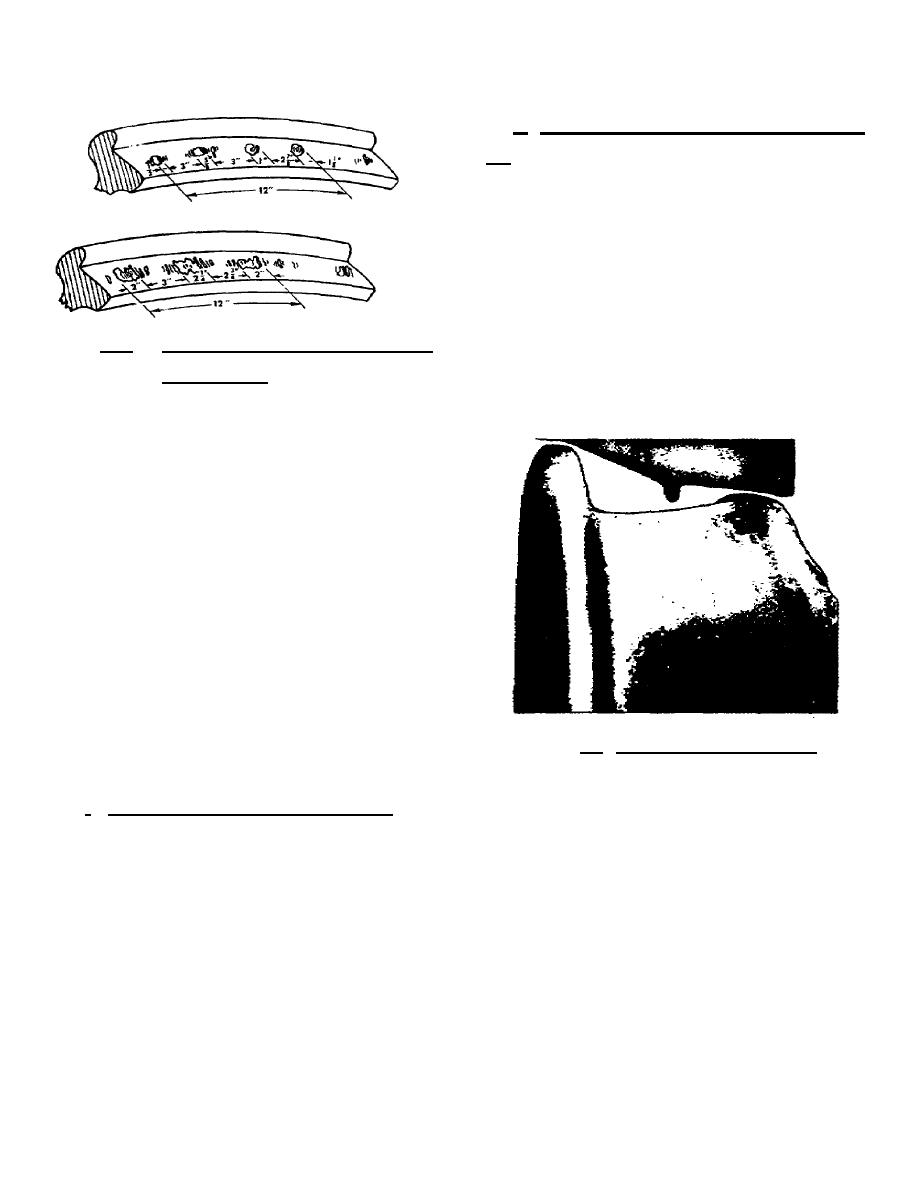

Figure 2.9 shows a condemnable wheel. If, however, the gage rocks back and forth

on the nipple when it is applied, the wheel is still

safe for service.

Many inspectors remove tread-

worn wheels before they reach the condemning

limits because they feel that they are dangerous and

hard on the track; however, condemning wheels

before they reach the gaged wear limits is wasteful.

It is important to note that very often when one

wheel is tread-worn, the mating wheel on the other

end of the axle has a worn flange. This develops

because the hollow tread on one wheel forms a false

Figure 2.9. Tread-Worn-Hollow Defect.

flange and tends to hold the flange of the opposite

wheel against the rail constantly.

i. Burst hub (Rule 77--AAR symbol 77). A burst hub is a radial crack in the hub. The burst or cracked

hub usually occurs when the wheel is pressed upon the axle. Three causes of the burst-hub defect are excessive

pressure, improper wheel-mounting methods, and improper taper in the wheel bore or of the axle seat. Any

wheel with a radial crack in the hub is condemnable.

20

Previous Page

Previous Page