d. Out-of-round (Rule 73--AAR symbol 73).

Although not dangerous, the out-of-round defect is

undesirable because of the damage it can cause to equipment, track, and lading when the car it is under is

traveling at high speeds. When the flattened area, regardless of the cause, is in excess of 3/64 inch within an arc

of 12 inches or less, measured in the center of the tread, the wheel is condemnable. Figure 2.3 shows the

application of the out-of-round gage for a wheel with a 33-inch diameter. Wheels with larger diameters must be

gaged with out-of-round gages made especially for wheels of their diameter; however, the size of the wheel for

which the gage is made is stamped on the gage.

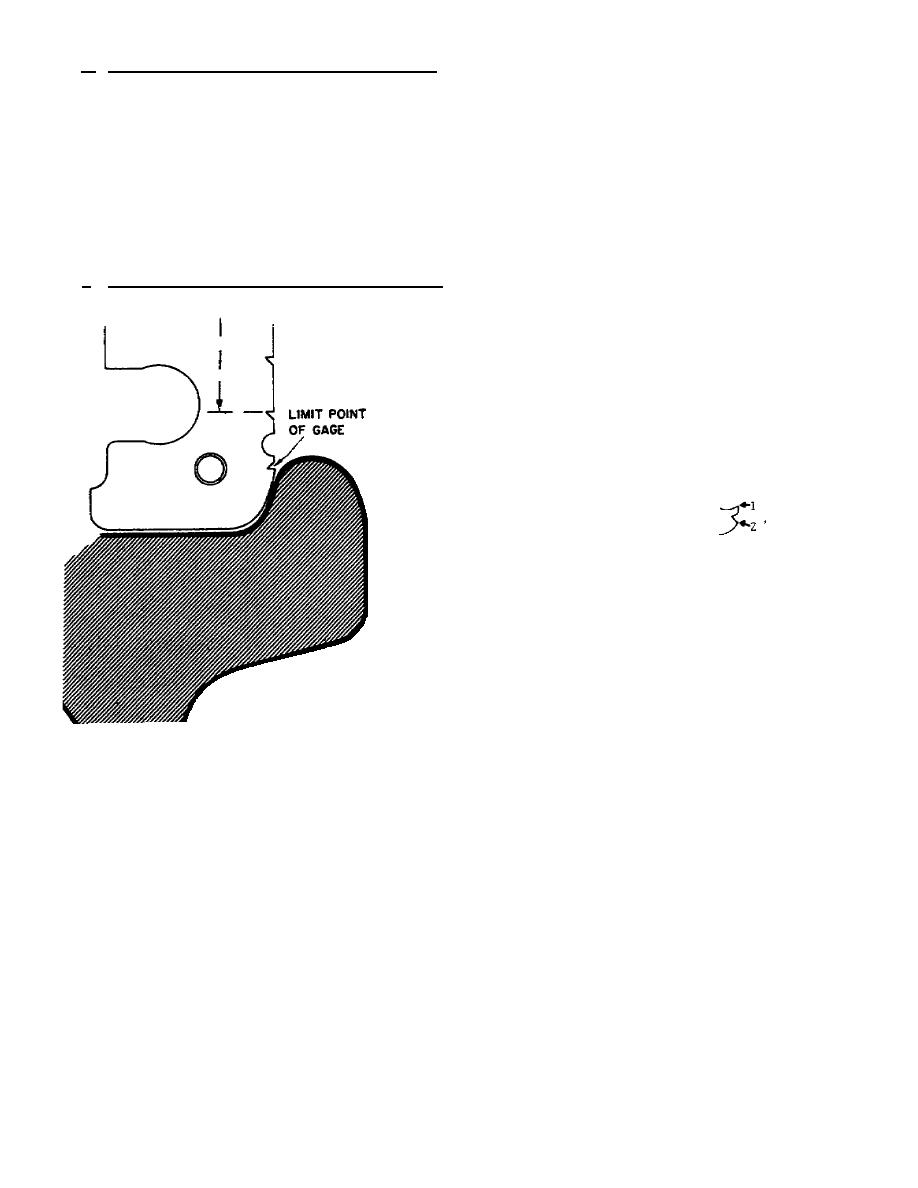

e. Vertical Range (Rule 74--AAR symbol 74-V). The inserted sketch shows a wheel-defect gage applied to

the flange of a new

wheel; note that the spot marked "limit point" does not touch the flange. As the wheel

rides

the rail, friction tends to wear down or flatten the inside vertical surface of the

flange, creating the defect called vertical flange or sharp flange. The sketch at

the top of figure

2.7 shows the wheel-defect gage applied to a flange worn

vertically; note here that the gage's limit point now touches the flange.

There are two limit points, a 1" limit and a 7/8" limit as seen in used

for two different car capacities: less than

80,000

pounds and 80,000 pounds or more. The

chief

danger of the vertical flange defect is that the flange may split a

switch (take the wrong side of the switch point) and derail the

equipment or break the switch point.

(1)

On cars of less than 80,000-pound capacity, a wheel is condemned when

the flat vertical surface of the flange extends 1 inch or more above the tread and thus

touches the gage at the 1-inch limit point.

(2) On cars of 80,000-pound capacity or more, a wheel is condemned when the vertically worn surface

of the flange extends 7/8 inch above the tread and touches the gage at the 7/8-inch limit point.

18

Previous Page

Previous Page