TM 55-203

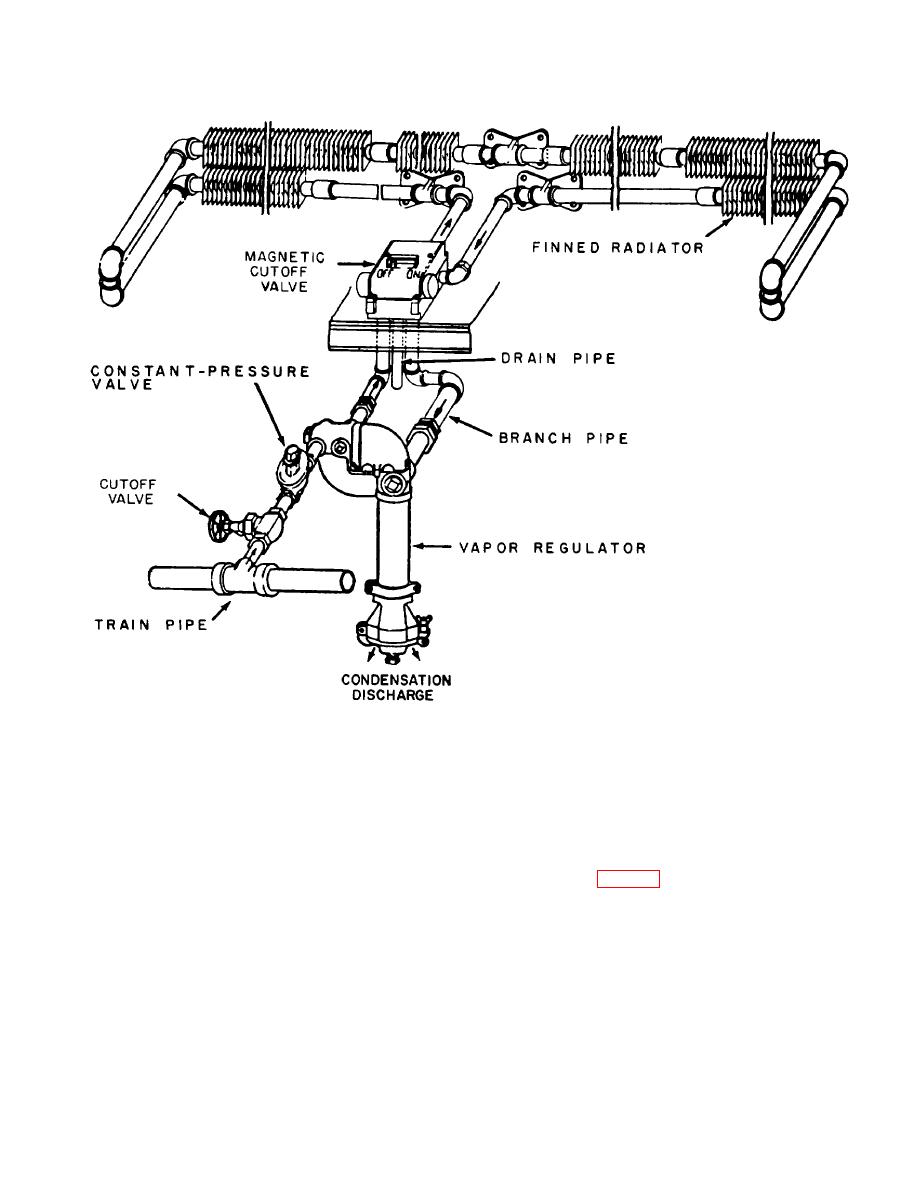

Figure 11-5. Automatic temperature-controlled vapor system.

When the car is shopped, the valve should be

11-8. Maintenance and Repair

disassembled and checked for wear, particularly the main

a. General. The two essential factors of steamheat

valve and seat. The bleeder valve, pins, cams, and

maintenance are the prevention of train delays through

levers should be checked for wear upon reassembly; the

steam-heat failures and the provision of car comfort for

valve should be tested under high-pressure steam for

passengers. This type of maintenance must often be

leaks and proper functioning.

performed during short layover periods at terminals. A

maintenance program will include thorough inspection

annually, preferably prior to the beginning of the heating

trainline crosses and tees, should be removed and

season. The principal sources of trouble are discussed

cleaned when a car is shopped. Normally, this is

below.

adequate attention.

b. End Train-Pipe Valves. The valve should be

d. Vapor Cutout and Drain Valve. The cutout and

operated from the platform to see that the linkage is in

drain valve located in each branch pipe should not require

operating condition and, also, from the weighted ball-type

maintenance if thoroughly overhauled when a car is

handle, to check the hold-open feature of the valve. In

shopped. If a constant steam leak exists at the drain port,

most cases, the valve stem will need repacking or the

it usually is indicative of a faulty back seat in the valve.

addition of a packing ring. The stem should have

This can be corrected by grinding the seat. This seat

sufficient packing so that subsequent packing nut

tightenings can be made by car inspectors as required.

11-4

Previous Page

Previous Page