CEMP-E

TI 850-02

AFMAN 32-1125(I)

1 MARCH 2000

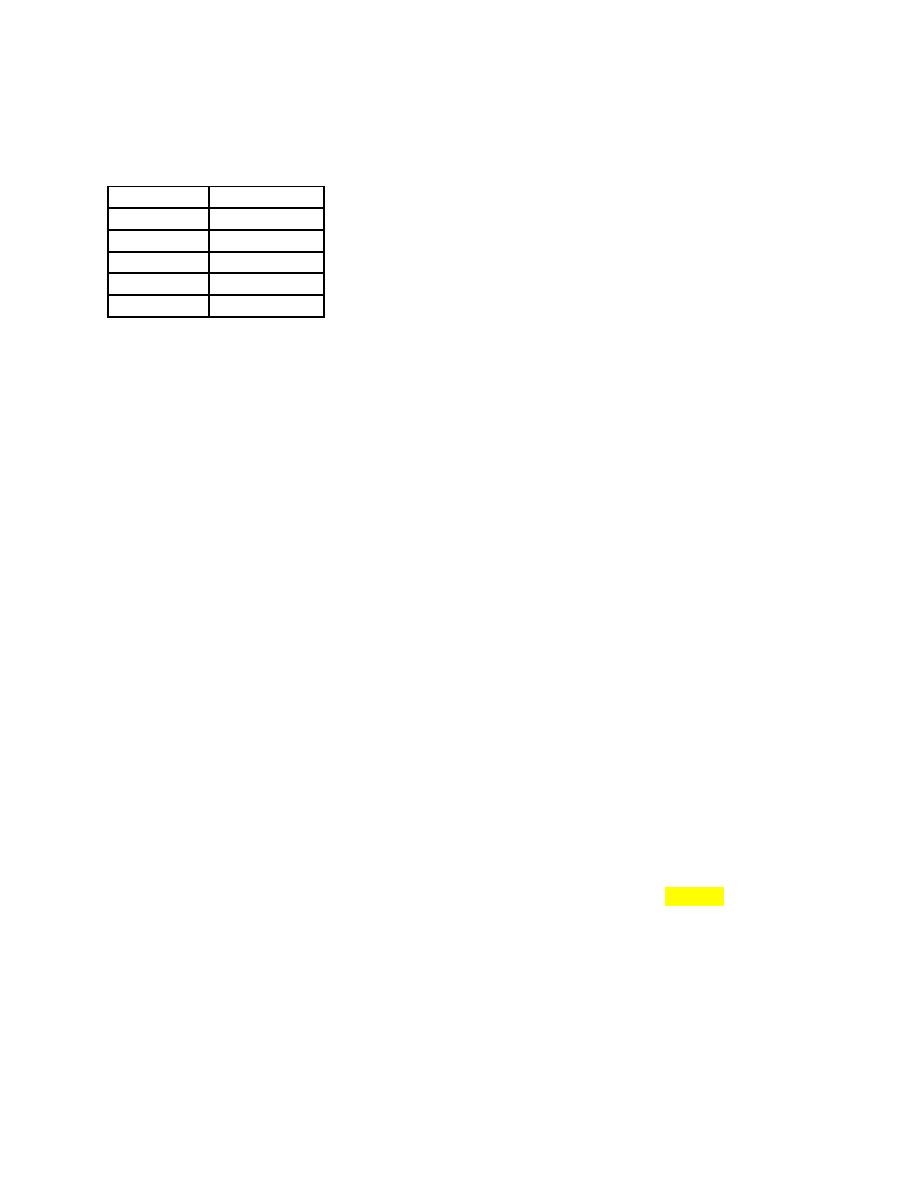

Hardwoods

Softwoods

Ash

Douglas Fir

Beech

Pine

Hickory

Spruce

Red Oak

White Oak

(2) Strictly defined, hardwood and softwood refer to a type of tree and not the hardness or density of

the wood. However, the hardwoods listed above are denser and generally more durable than the listed

softwoods and thus usually more desirable for ties. While softwoods are sometimes preferred on open

deck bridges to help absorb impact, they are not recommended for use in turnouts or in sharp curves

(over 8 degrees) where the better spike-holding ability of the denser woods is needed.

(3) Hardwood ties are often sold in species groups such as mixed hardwoods or oak. The mixed

hardwoods may comprise, for example, 40 percent oak and 60 percent assorted hardwoods, including

gum. Gum is not a preferred species, but is commonly used. The oak group is usually a mix of red and

white oak and typically costs more than the mixed hardwoods.

(4) For track with annual traffic volumes of 5 MGT or less, as is common at military installations,

wood ties are more likely to fail from decay rather than mechanical wear or loss of spike-holding ability. In

such cases, tie selection should lean toward available species that readily accept deeply penetrating

preservative treatment. Information from the engineering department of the serving commercial carrier,

from regional tie suppliers, and from local experience should help in selecting the most appropriate ties.

b. Cross-Section and Length.

(1) The two common cross sectional sizes for wood track ties are 7 in. thick by 9 in. wide or 6 in. thick

by 8 in. wide.

(2) 7x9 ties are recommended for areas with higher traffic volumes and wheel loads as well as in

turnouts and in road crossings.

(3) Track ties are commonly produced in 8.5 or 9-ft lengths. The 8.5-ft length will be used when most

conveniently available.

(4) Ties for turnouts vary from 9 to 16 ft long and will be ordered as indicated in table 6-9.

6-30

Previous Page

Previous Page