CEMP-E

TI 850-02

AFMAN 32-1125(I)

1 MARCH 2000

distribute loads from the ballast and prevents ballast particles from being pushed into the subgrade. A

sub-ballast layer is required whenever:

(1) The subgrade contains 85 percent or more (by weight) of silt and clay sized particles, or

(2) The subgrade material has a liquid limit greater than 50 and a plasticity index greater than 20.

c. Material. Sub-ballast should be a hard, angular, non-cementing material, primarily of sand-sized

particles.

d. Gradation.

(1) To function well as a filter layer, the sub-ballast particles should range in size from the smallest

ballast particles the largest subgrade particles.

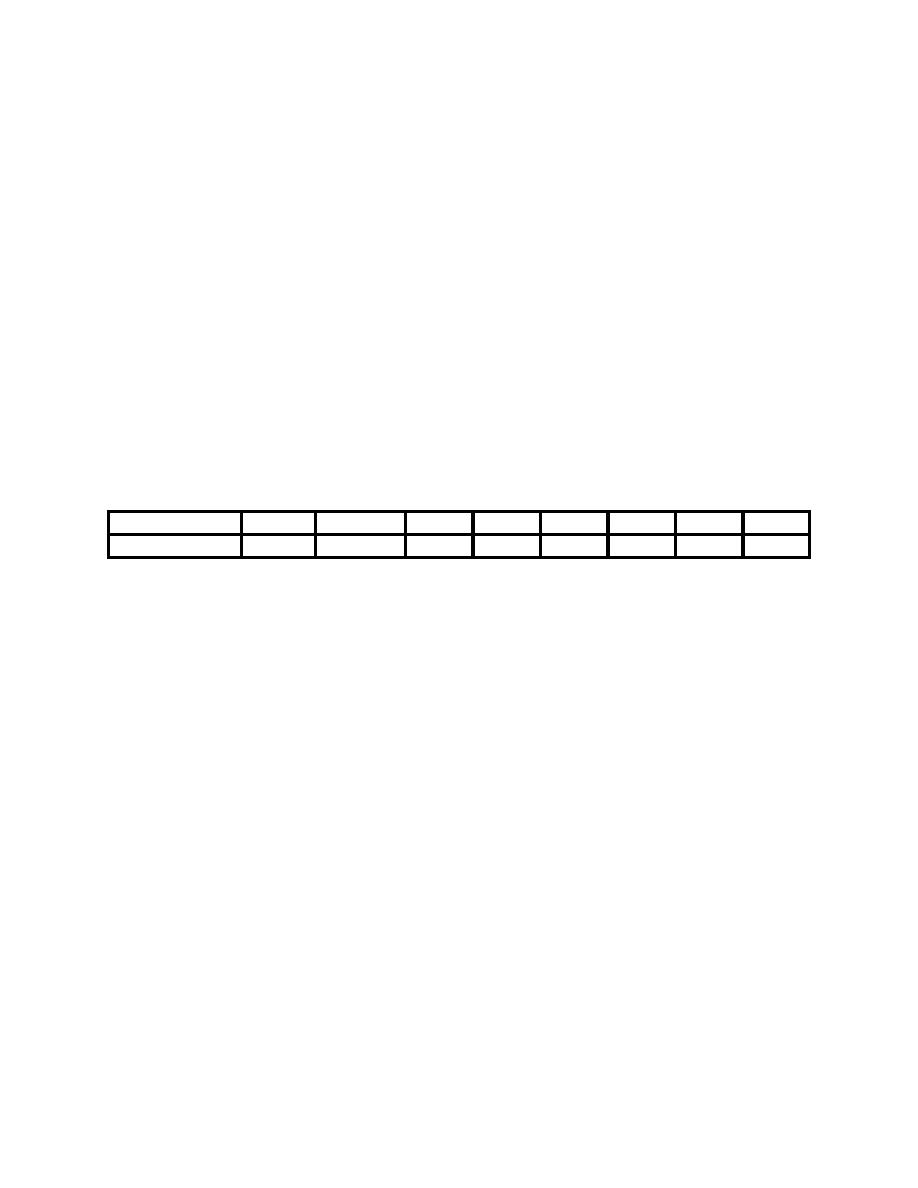

(2) Over a clay or silty clay, with greater than 85 percent passing the no. 200 sieve, the following

gradation is recommended:

Sieve Size

in.

3/8 in.

#4

#10

#20

#40

#100

#200

Percent Passing

100

90

80

70

50

40

20

10

This gradation can be approximated by specifying ASTM D1241 gradation C or the somewhat finer

gradation D.

(3) Over a subgrade with more than 15 percent larger than no. 200, either of the following should

suffice: a sub-ballast of AASHTO gradation C19, or ASTM D1241 gradation C.

e. Depth.

(1) During structural analysis, the sub-ballast layer is considered as part of the total ballast depth.

(2) A sub-ballast layer may comprise up to 40 percent of the total ballast depth on main running

tracks and up to 50 percent on auxiliary and terminal tracks.

(3) When used, the minimum sub-ballast thickness will be 4 in. with a minimum total ballast depth of

10 in.

14. TIES AND TIE SPACING.

a. Material.

(1) In most cases, wood is still the most cost-effective tie material. Wood ties will meet the

requirements in chapter 3, part 1 of the AREMA Manual. The recommended species of wood for cross

ties are:

6-29

Previous Page

Previous Page