CEMP-E

TI 850-02

AFMAN 32-1125(I)

1 MARCH 2000

(2) Common rock materials suitable for ballast are granites, traprocks, quartzites, dolomites, and hard

limestones. As limestones degrade, they tend to produce fine particles that cement together, and are

thus not the best ballast choice if other hard rock material is economically available. Crushed slag can

also vary greatly in quality and suitability for good ballast.

c. Gradation.

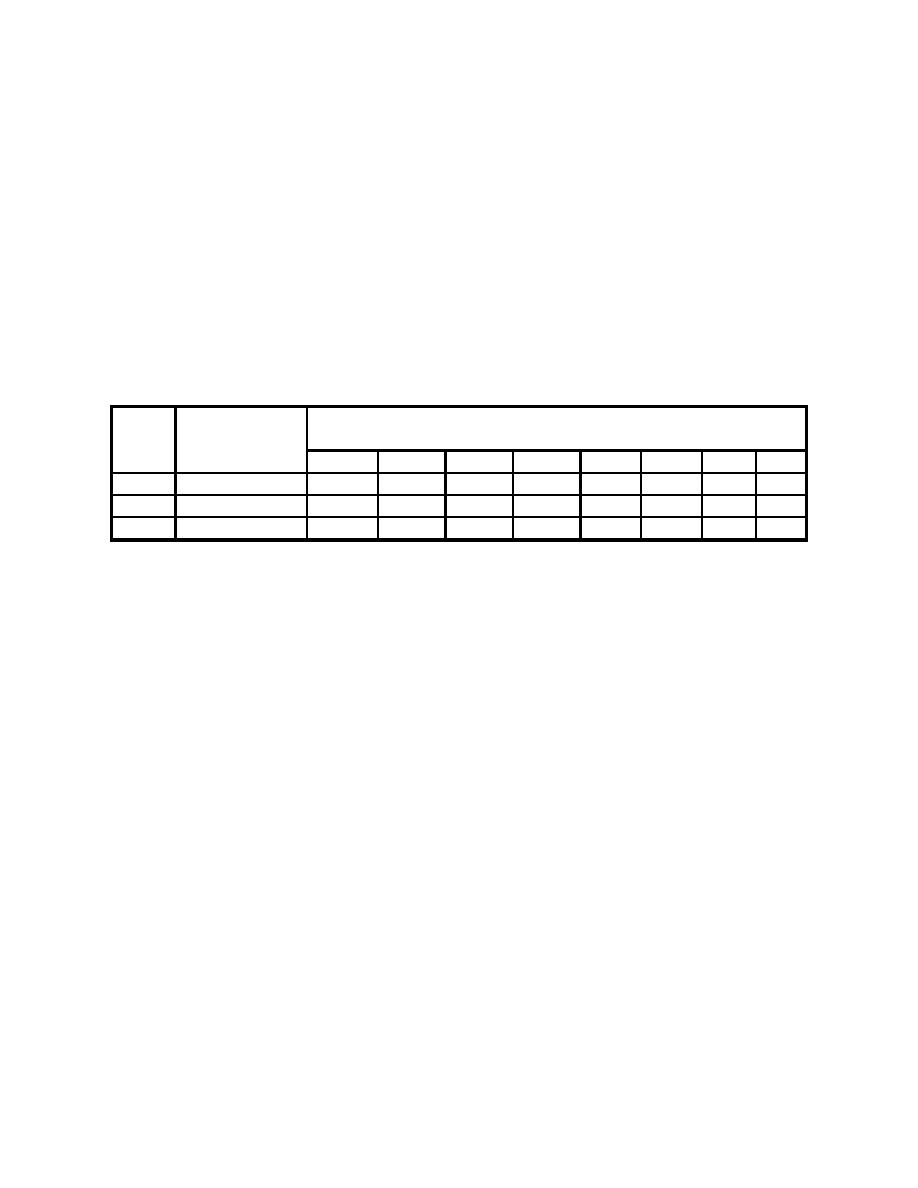

(1) Table 6-8 gives recommended AREMA ballast gradations. For main running tracks, sizes 4A and

4 will be used. For loading tracks in terminal areas, size 5 may be used to facilitate easier walking along

the cars during loading and unloading operations, but a larger size is preferred for long-term track

maintenance. AREMA ballast gradation 4 is identical to ASTM C33 gradation 4. ASTM C33 gradation 56

is close to AREMA no. 5.

Table 6-8. Recommended Ballast Gradations

Amounts Finer Than Each Sieve (Square Opening)

Nominal Size

Percent by Weight

Square Opening

Size No.

2-1/2 in.

2 in.

1-1/2 in.

1 in.

3/4 in.

1/2 in.

3/8 in.

No. 4

(in.)

4A

2 to 3/4

100

90-100

60-90

10-35

0-10

0-3

4

1-1/2 to 3/4

100

90-100

20-55

0-15

0-5

5

1 to 3/8

100

90-100

40-75

15-35

0-15

0-5

(2) For smaller projects, where less than 200 tons of ballast is needed, and where the nearest

suppliers do not stock AREMA gradations, the following AASHTO (highway) gradations may be

substituted: CA5 for AREMA 4 or 4A, and CA7 for AREMA 5.

d. Depth.

(1) Appropriate ballast depth will be determined by structural analysis using the computer program

specified in paragraph 6. The manual method described in paragraph 7 may also be used, but is not

preferred.

(2) In all cases, the minimum depth of ballast from the bottom of the tie to the subgrade will be 8 in. In

most cases, however, main running tracks will require more.

e. Cross-Section. Figures 6-1 through 6-7 show standard ballast shoulder widths and side slopes. In

finished or resurfaced track, the top of ballast may be up to 1 in. below the top of the tie, but never above

the top.

13. SUB-BALLAST.

a. Purpose. Sub-ballast is a layer of material between the top ballast and subgrade with a gradation

finer than the top ballast and coarser than the subgrade. Sub-ballast is often cheaper than top ballast, so

it can be used to reduce total ballast cost or to provide a filter layer between the top ballast and a fine-

grained subgrade. Figures 6-2, 6-4, 6-5, and 6-7 show sub-ballast layer.

b. Application. A sub-ballast layer is recommended for most new construction. In addition to providing

a filter to keep subgrade particles from working up into and fouling the ballast, it provides a good mat to

6-28

Previous Page

Previous Page