published by the AAR. The rule numbers and AAR

symbols are given with the defects in the following

sub-paragraphs.

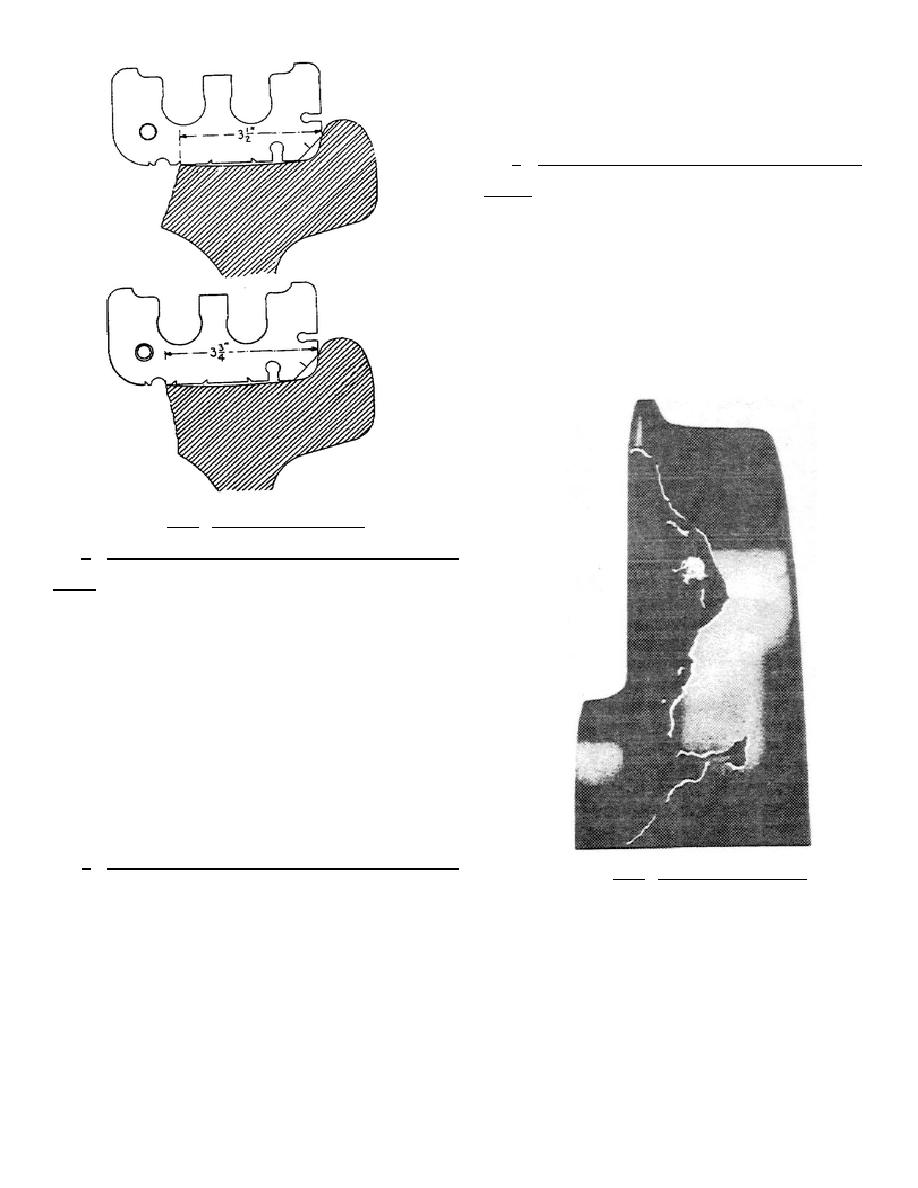

a. Burnt rim or flange (Rule 71--AAR symbol

71-A). If a portion of the flange or rim breaks off

with a coarse fracture and a rough granular surface

shows, the wheel should be removed from service.

The cause of the burnt-rim or -flange defect is

overheating during the manufacturing process. The

wheel shown in figure 2.13 has a burnt-flange

defect.

Figure 2.12. Gaging Broken Rims.

b. Shattered rim or flange (Rule 71--AAR symbol

71-B). When a portion of the rim or flange parts from

the remainder of the wheel so that a smooth surface is

exposed for any considerable distance, the defect is

known as a shattered rim or flange. The wheel should

be removed from service, and a heavy coating of grease

should be applied to the exposed area to preserve the

defect, as originally detected, for investigation. Look at

figure 2.14 and notice the difference in this defect as

compared to the burnt flange shown in figure 2.13.

c. Spread rim (Rule 71--AAR symbol 71-C).

Figure 2.13. Burnt-Flange Defect.

When the front or the back face of the rim spreads

outward from the tread, the wheel has a spread-rim defect as shown in figure 2.15. This condition usually

indicates an interior defect,

22

Previous Page

Previous Page