mounting and axle bearings and caps and inspect axle gear. Clean and lubricate brake cylinders, check

slack adjusters, and inspect and repair the complete airbrake equipment.

Jacking pads are provided on the body of the locomotive to support the locomotive frame

when raising it from a truck. To remove a wheel and axle assembly without removing the truck, use a

drop table. Give axles and axle gears nondestructive inspection, magnetic particle preferred, each time

wheels are removed. If the second pair of wheels is worn to its condemning limit but the axle and axle

gear are free of cracks or defects and the gear is not to the condemning limits, new wheels may be

applied using the same axle and axle gear. If the axles are not inspected at each wheel removal, it is

recommended that the axle be scrapped after two pairs of wheels have been worn to their condemning

limits. Axle gear, if not subjected to nondestructive inspection, should not be used beyond the life of

two axles. When a pair of new wheels is to be mounted on an axle, the wheels must be carefully mated

with a maximum variation of 1/16 inch in circumference, or 0.020 inch in diameter. If new wheels are

not available within these limits or variations, or if old wheels are to be used, they should be matched as

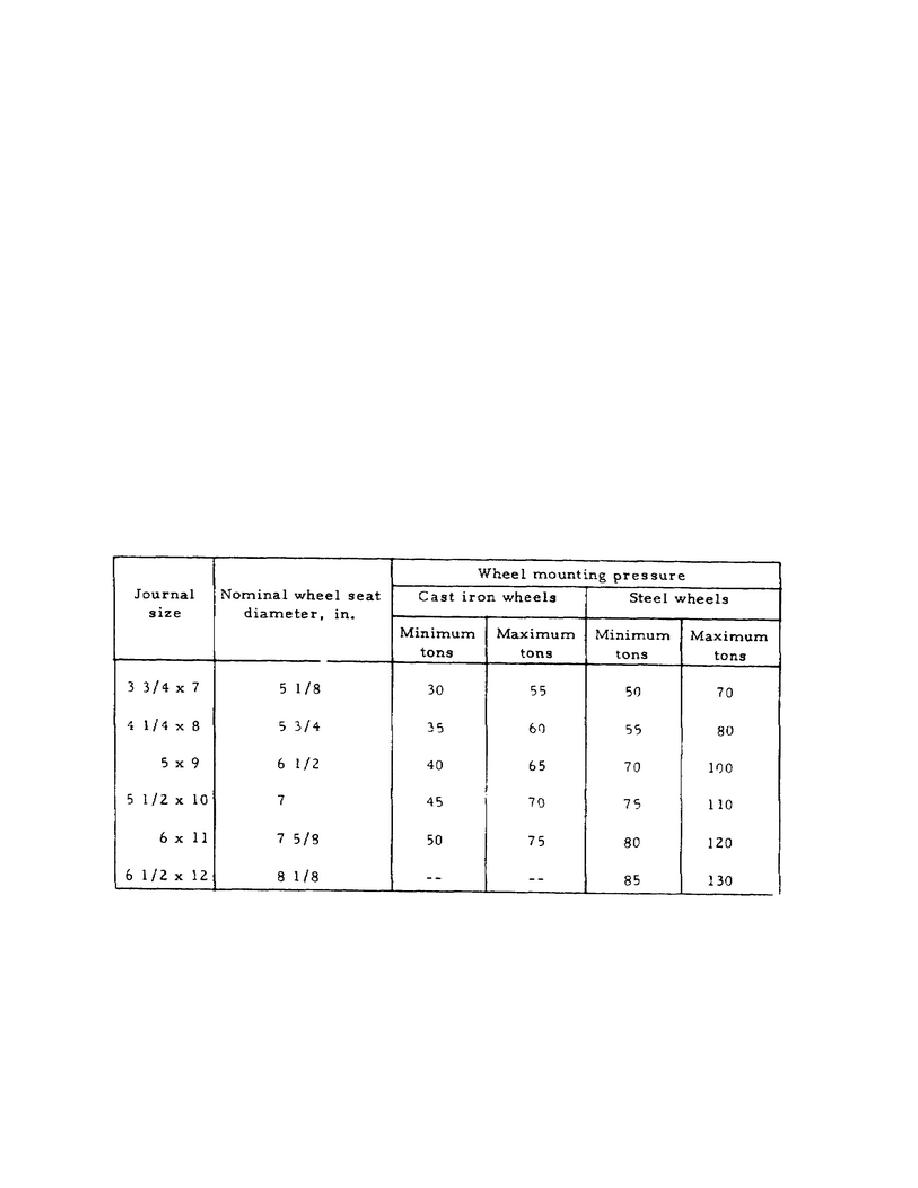

closely as possible and turned or ground after mounting. Wheel mounting pressures referred to in the

following table are used when pressing wheels on axles.

Wheel Mounting Pressures in Tons

Minimum and Maximum Pressure Limits are Absolute--

No Tolerance Permitted

56

Previous Page

Previous Page