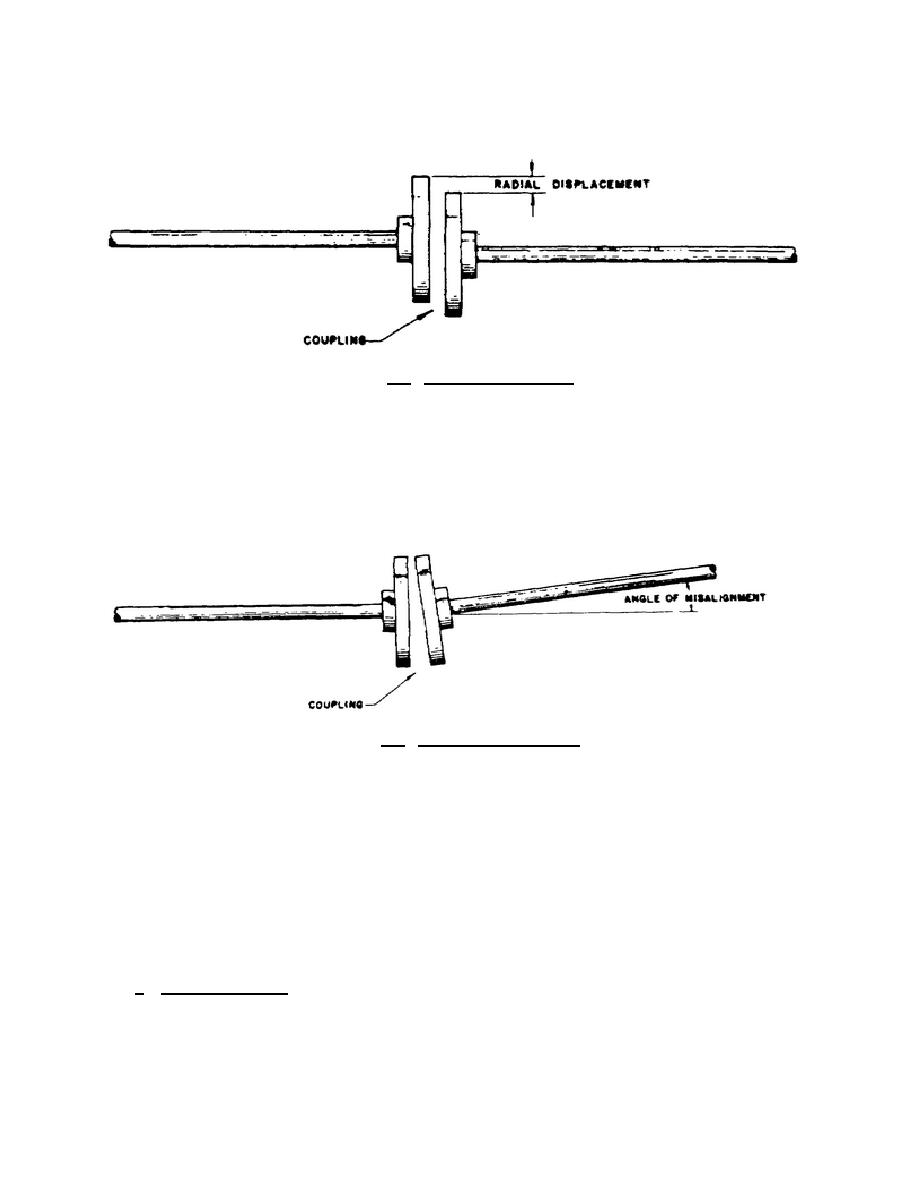

Figure 2.2. Radial Misalinement.

b. Angular misalinement. When the two shafts come together at a slight angle, angular

misalinement, illustrated in figure 2.3, is present. In addition to setting up vibration, such misalinement

causes bending stresses to be set up in the shafts and results in additional bearing loads. The more

flexible the coupling, the less will be the load on the bearing and the less stress will be set up in the

shaft.

Figure 2.3. Angular Misalinement.

2.7.

TRUCKS

Clean and lubricate trucks as required by maintenance schedules and lubrication orders. When

inspecting trucks, check main castings, pedestal liners, and swing hangers for damage or wear; bolts,

nuts, and other fittings for tightness; center plates and side bearings for excessive wear; and springs for

weakness, cracks, or broken leaves. In addition, test equalizers with a magnetic tester.

Maintenance of wheels and axles and of journal boxes is a little more detailed, involving more

than a routine check for wear.

a. Wheels and axles. Wheels and axles may have to be turned or renewed. If the wheels are to

be renewed, remove them and the axles and test them by the magnetic method. Repair motor

55

Previous Page

Previous Page