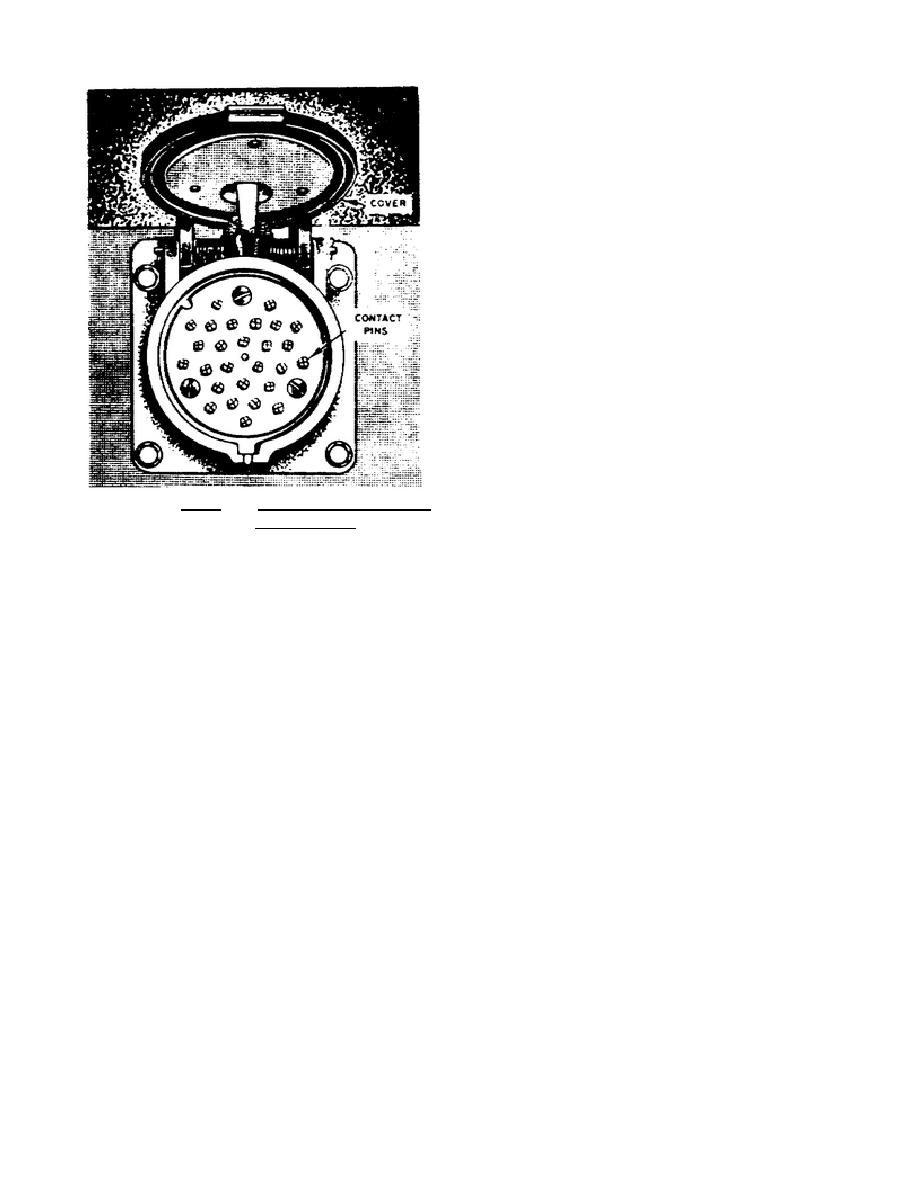

containing the control wires is

inserted in the end receptacle to

make the connection.

Each end

receptacle should be inspected for

cracks in the insulation, bent or

broken contact pins, and broken

cover

springs.

Figure

2.16

pictures a typical multiple-unit

end receptacle; note the 27 contact

pins.

2.18. SUMMARY

An

effective

preventive

maintenance program is necessary to

guard

against

breakdown

of

equipment and reduce the expense

involved

in

replacing

parts.

Although checklists and guidelines

may

be

provided

for

making

preventive maintenance inspections,

a good inspector does not limit

Figure 2.16.

Multiple-Unit End

himself to a set list but observes

Receptacle.

his equipment keenly for any sign

of developing defects.

A locomotive operator, for example, observes the

instrument panel in the cab containing the various gages and controls. They

include air pressure gages, oil pressure gages in the engine lubricating

system, and water temperature gages.

Excessive deviations from normal

readings on the gages may point out deficiencies that could develop into

serious defects.

Section III.

Inspection and Maintenance Forms

2.19. GENERAL

Publications governing the inspection and maintenance of Army diesel-

electric locomotives require the use of various forms and records.

This

section contains only a general discussion of them.

For details on

preparation and distribution, the units responsible for inspecting and

maintaining the equipment must have the appropriate publications on hand and

follow the instructions therein.

Technical Manual 38-750, The Army

Maintenance Management System (TAMMS), and Technical Manual 55-202,

Operation and Maintenance of Diesel-Electric Locomotives, are the two

needed.

27

Previous Page

Previous Page