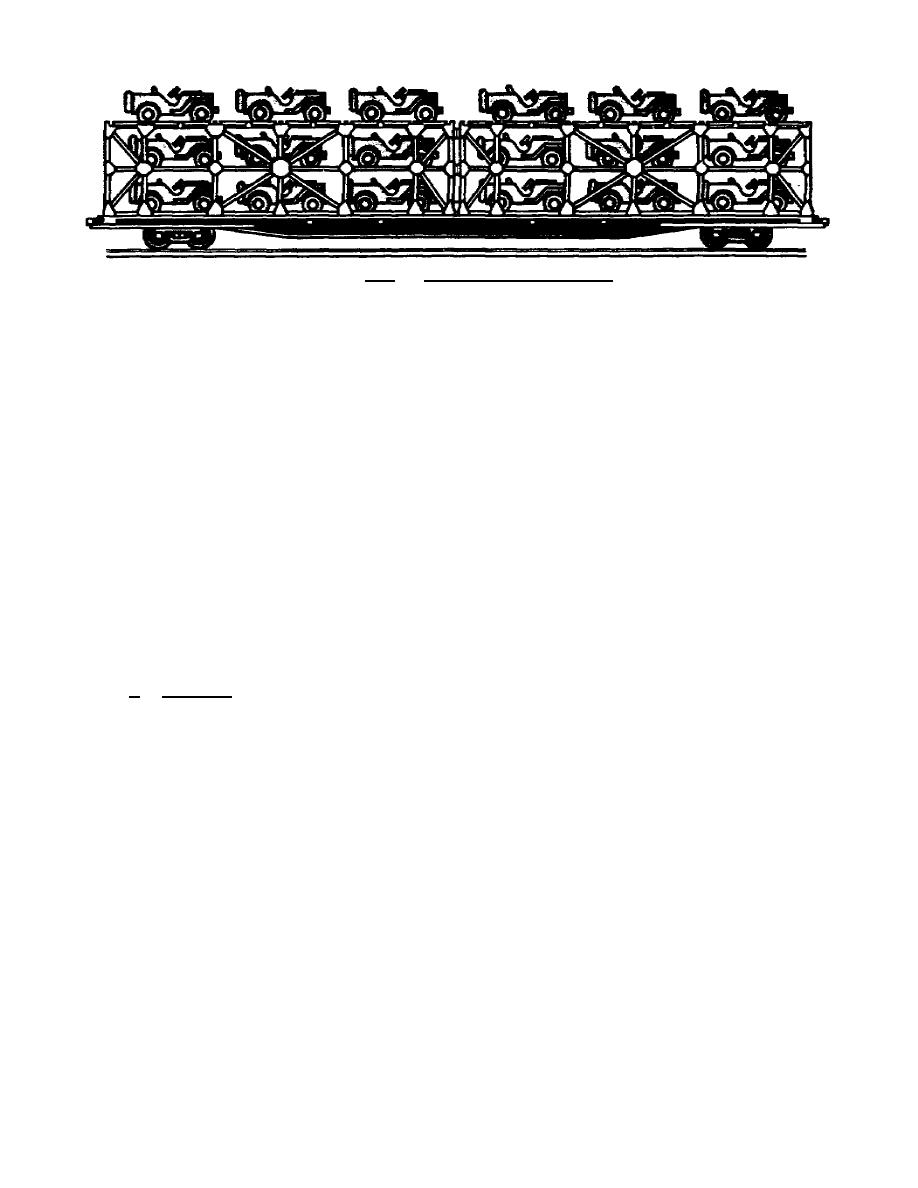

Figure 1.4. Multilevel Rack Car.

adequate and efficient rail transportation. Movements of new automobiles

from factories to dealers in rack cars are steadily increasing; the number

of automobiles carried runs into several million annually.

The piggyback car, shown in part A of figure 1.5, is noted for its

shockabsorbing qualities. They are provided by the mechanism shown in part

B of figure 1.5; the encircled numbers in it are referred to in the next few

sentences. On either side of the center sill (A) is a cushioned rub rail

(B) with a pocket (C) every 12 inches. A special tiedown device (D) is

snapped securely into place in one of the pockets. Two chains (E) are

fastened to both the tiedown device and the equipment being shipped. After

that, the device is locked. When the car is subjected to a substantial

impact, springs in the chains expand as much as 8 inches to absorb possible

shock to the loaded equipment. The devices and chains eliminate the usual

blocking required in rail shipments, thereby saving loading time and costs.

Results of test loads of military vehicles and guided missile systems on

rubrail cars reveal that the damaging forces ordinarily present in rail

shipments are substantially lessened by the shockabsorbing feature of the

cushioned rub rails.

c. Caboose. Attached to the rear of the train is the caboose; a

typical one is shown in figure 1.6. The train conductor and the rear

brakeman ride the caboose, and emergency and safety equipment is stored in

it. With the engineer, the fireman when on board, and the head brakeman

riding in the locomotive cab, the train is easily protected at both ends

when an emergency or unscheduled stop occurs on the main line. The

caboose's cupola and lookout windows provide the occupants with a unique

vantage point from which to view the train.

6

Previous Page

Previous Page