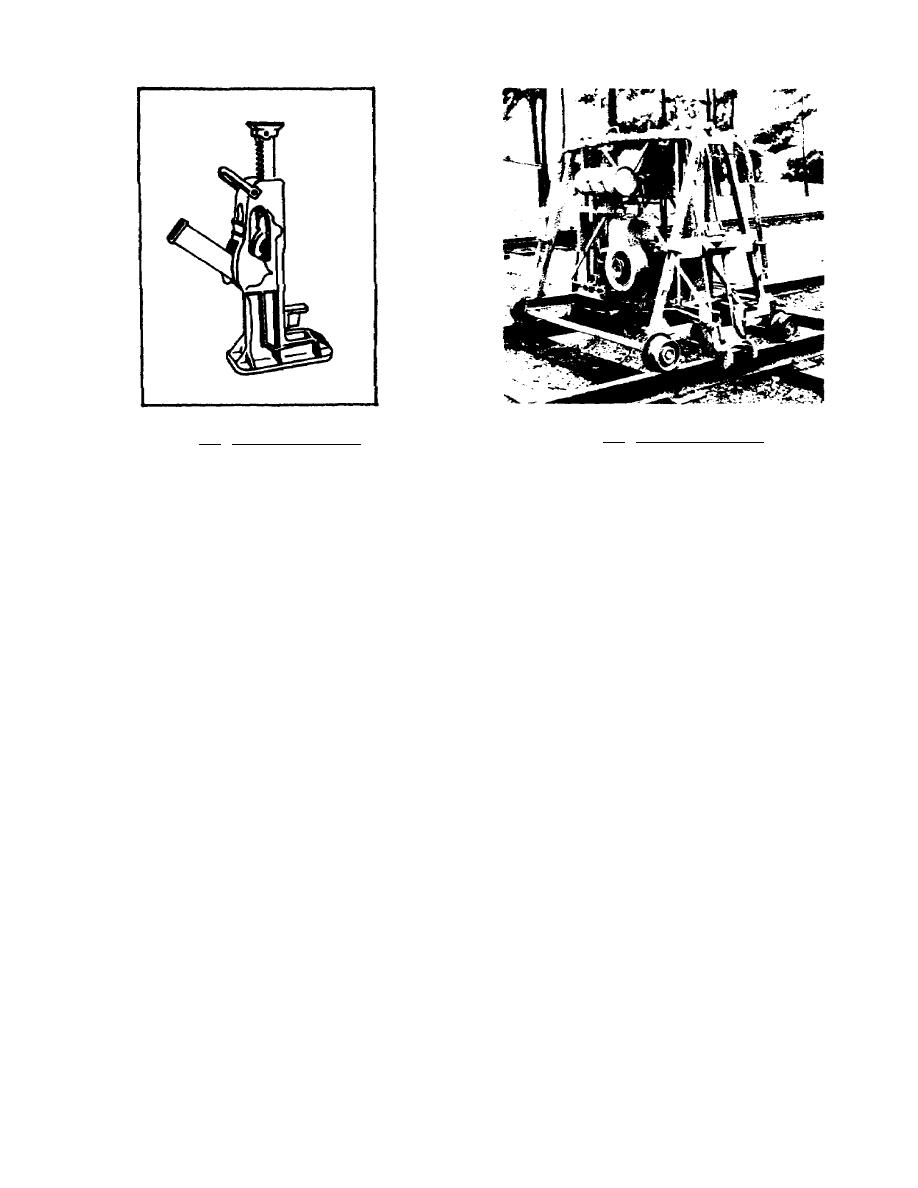

Figure 1.6. Rail-Mounted Jack.

Figure 1.5. Ratchet-Type Jack.

When one rail has been raised to proper height with the spot board, the adjacent rail can be brought to

proper surface by using the track level. Then the spot board is moved on to the next grade stake and the process

repeated.

1.6.

PLANNING

Together the track supervisor and the track foreman must estimate the length of track that can be raised

in 1 day. This is based on the number of men in the surfacing gang, the type of tools, the type of ballast, the

amount of raise, and the skill of the crew. In a theater, you will ordinarily have only the handtools in

Maintenance-of-Way Tool Set No. 4. The set includes track shovels, ballast forks, tamping bars, picks, track

jacks, and spot board equipment, shown in figure 1.7. However, if you have such power tools as the pneumatic

and electric tampers shown in figures 1.8 and 1.9, your surfacing work will move along much faster.

1.7.

CALCULATING THE AMOUNT OF BALLAST

After figuring the length of track to be surfaced in a day, the track supervisor and the track foreman can

estimate, based on experience, the amount of ballast required. Or they can calculate the amount by multiplying

the width of ballast section by the projected raise and then by the length. In calculating, they are careful that all

dimensions are expressed in the same units. For example, if the

11

Previous Page

Previous Page