grade rail is the same as the line rail, as paragraph 1.23 explains; on a curve, the grade rail is the low or inner rail.

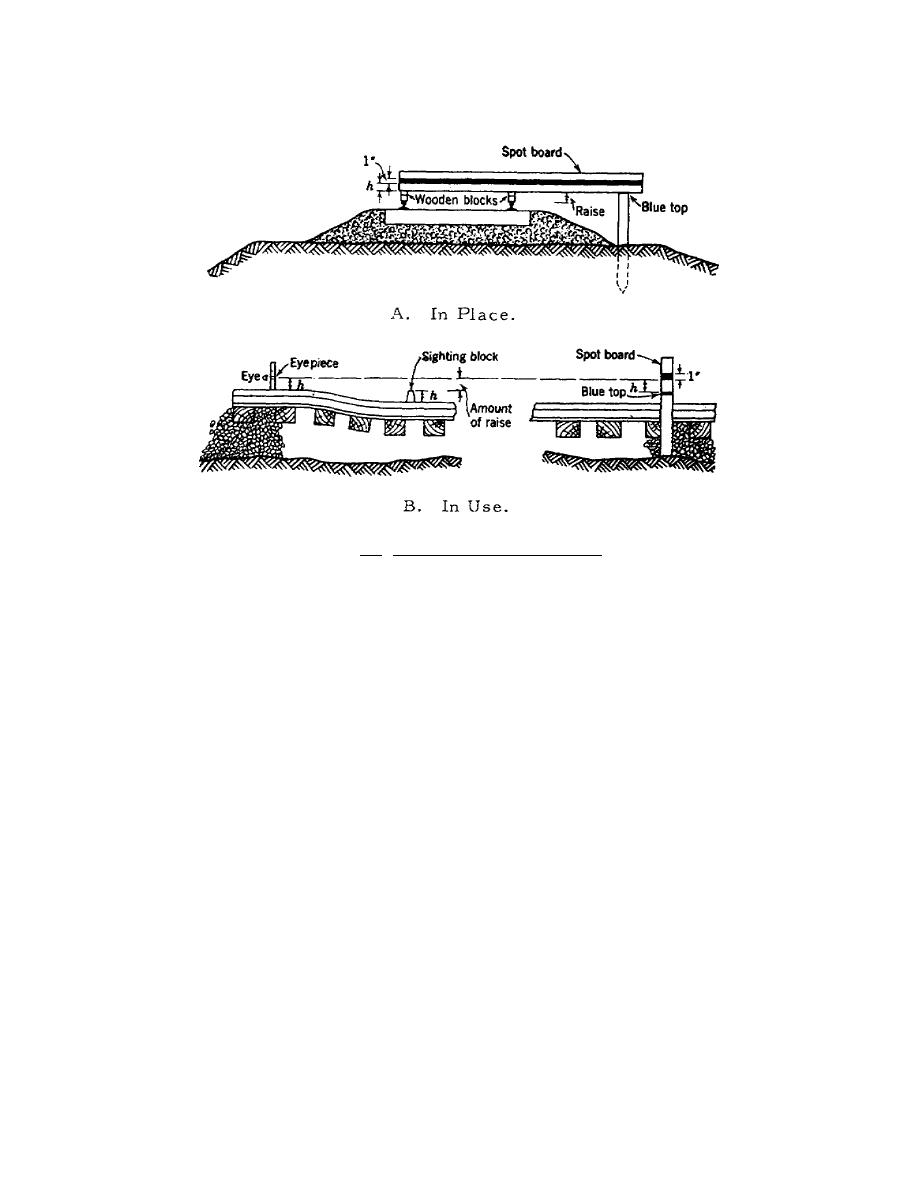

A spot board, shown in figures 1.3 and 1.4, is laid across both rails with one end

Figure 1.4. Spot Board in Place and in Use.

resting on a grade stake 20 or 30 feet beyond the point where the raise is to be made. Note the horizontal sighting

band of contrasting color on the face of the spot board. Wooden blocks or shims are placed between the rails and

the board, to elevate it until the top is level, as shown by the track level. A triangular sighting block, of the same

height as the distance between the sighting band and the bottom of the spot board, is placed on each rail at the

point where the track is to be raised. Jacks are then applied at that point. They must always be set on the outside

of the track to permit easy removal. A sighting block with a peephole sight is placed on the same rail where the

last raise was made. A workman looks through the peepsight along the rail at the sighting band, and the jacks are

operated to raise the track. A ratchet-type jack is shown in figure 1.5; a rail-mounted jack in figure 1.6. When

the top of the sighting block is level with the sighting band as seen through the peepsight, the rail is at the correct

height, that is, level with the top of the grade stake. Ballast is then forced under the ties to give temporary

support until the tamping gang arrives to tamp the ballast. If the track level shows that a rail is too high, that is,

above the grade stake, ballast is removed to lower the rail, and it is then jacked up to proper height.

10

Previous Page

Previous Page