crossovers, bridges, tunnels, main-line curves, and other curves exceeding 3 degrees.

3.21.

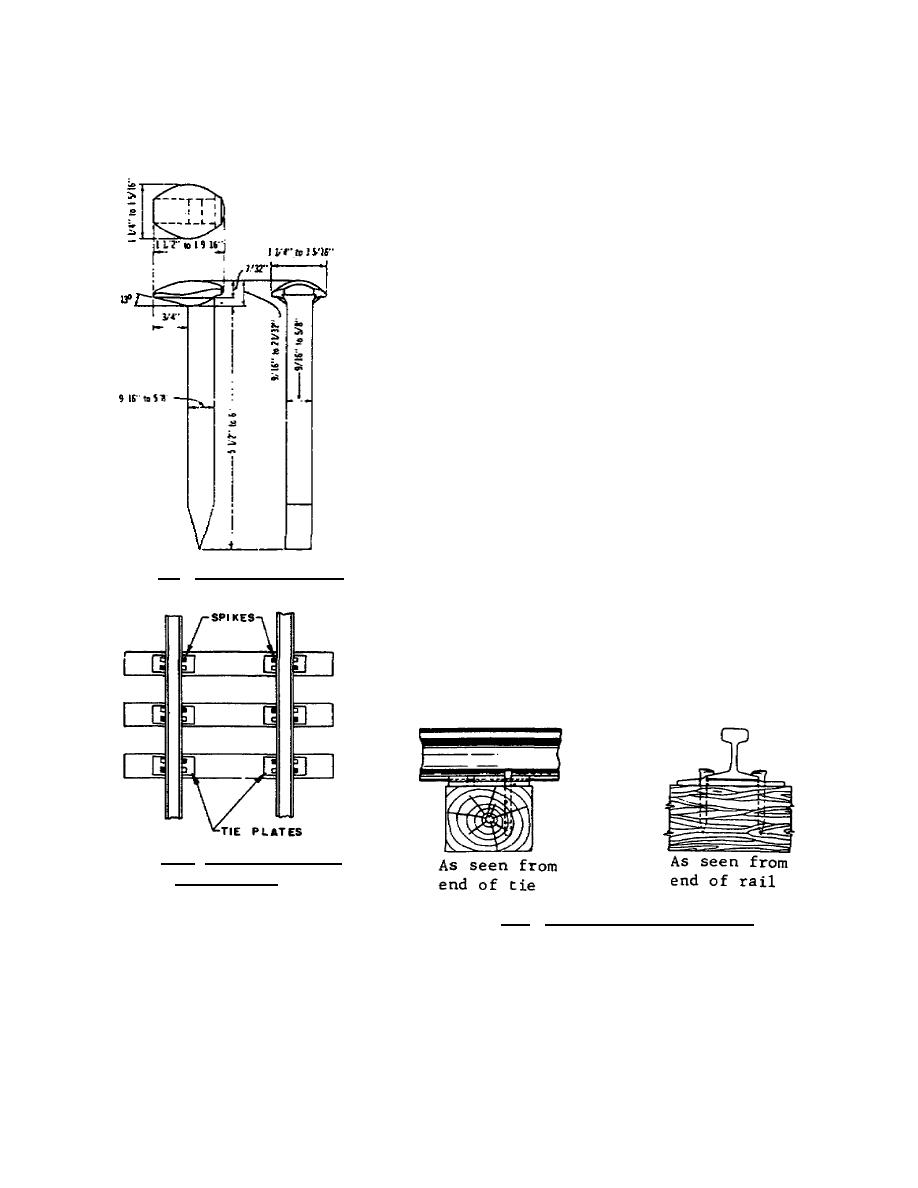

SPIKES AND TIE PLUGS

Track spikes fasten T-rails to ties, hold track in

gage and line, prevent rail from overturning, and hold tie

plates in place. The ordinary spike used in the United

States has a square shank and a hook head. It is used to

fasten rail either directly to the tie or to the tie with an

intervening tie plate. Figure 3.9 shows the details of a

cut, or hook head, track spike. The spike is driven with

the chisel point parallel to the direction of the track and

with the head overlapping the rail flange. On tangent

track, one spike on each side of each rail on each tie is

sufficient (fig. 3.10). On curved track, additional spikes

are required. Figure 3.11 shows you how a driven spike

appears when a tie plate is in place.

Spikes may be driven by hand, by using a spike

maul, or with an automatic spiking machine. When

manually driven, care should be taken that the rail base

is not struck accidentally. Such a blow may eventually

cause rail failure.

Figure 3.9. Details of Cut Spike.

Some railways in Europe and elsewhere use screw

spikes more extensively than hook head spikes. One is

shown in figure 3.12. The holding power of a screw

spike is nearly three times that of a cut or hook head

spike. On the other hand, they are driven much more

slowly, even with

Figure 3.10. Correct Method of

Setting Spikes.

Figure 3.11. Using Spikes With Tie Plates.

58

Previous Page

Previous Page