least twice within the first 10 days after installation--first, within a day or so and again, within a

week or 10 days.

Only when all bolts and nuts are in place and properly tightened can a rail joint

provide the support that it is designed to give. Missing bolts and nuts should be replaced when

their loss is first noticed.

3.30. COMPROMISE JOINTS

Often it is necessary to join tracks of different rail sections. Light-traffic branch lines

must join main-line tracks; sidings and yard tracks of light rail must join heavy running tracks.

In addition, replacing main-line rail often requires that rail of different weights be joined in the

same track.

These and other similar

problems are solved with compromise

joints.

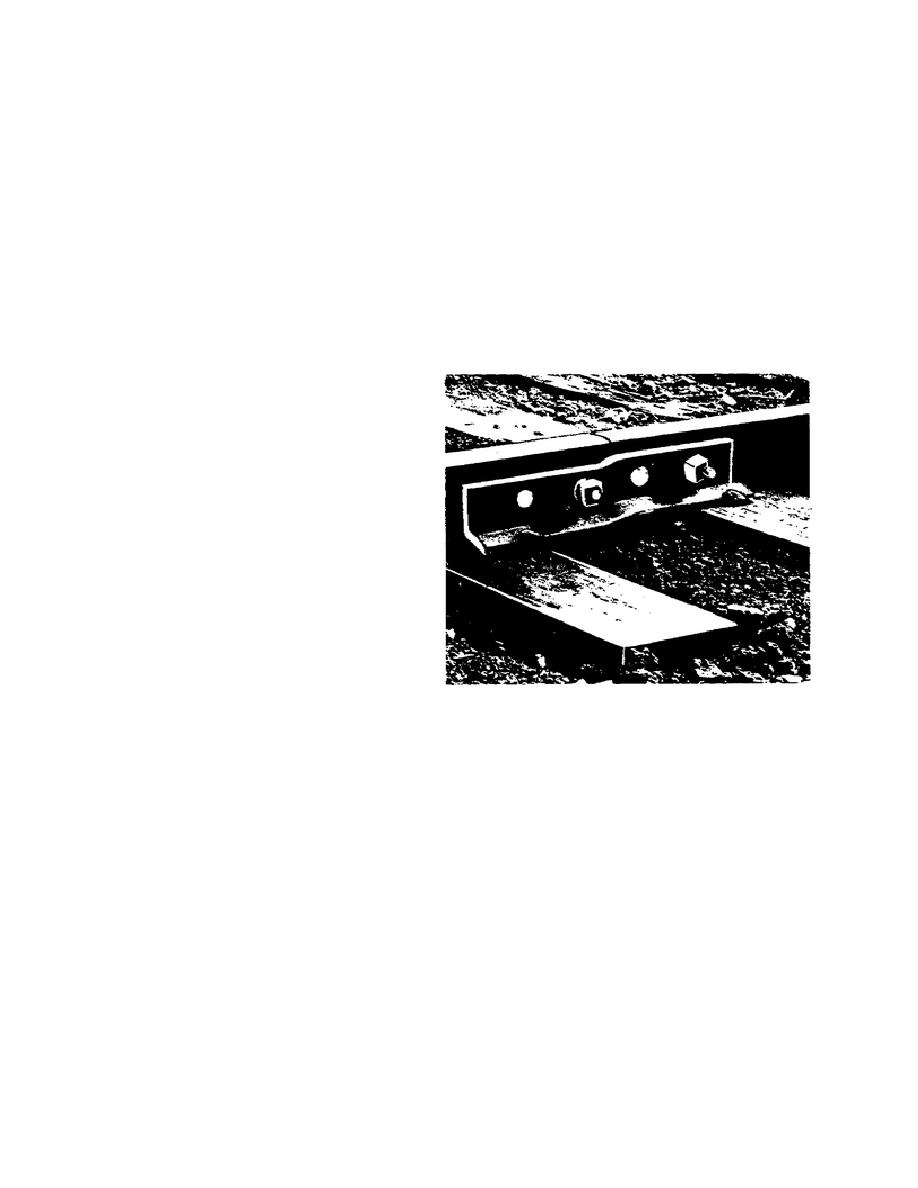

The compromise joint, or the offset

or step joint as it is sometimes called, is a

variation of the simple bar joint, using bars

made so that half the bar fits one rail section

and the other half fits another. A typical

compromise bar is shown at the right

installed on the field side of a rail; another

bar is installed on the gage side of the same

rail. Compromise joints are designated

either right or left handed. Standing inside

the track and looking at the joint, if the

larger and heavier rail is on your right, then

the joint is right handed. If the larger, heavier rail is on your left, then the joint is left handed.

These designations are diagramed in figure 3.22.

Compromise bars compensate for differences in web thickness, head width and depth,

height, and location of boltholes. A pair of compromise joints holds the smaller rail so that its

top and gage side meet those of the heavier rail. When compromise joints are ordered, the two

rail weights and sections and the direction of the joints are specified. Compromise splices are

common in theaters because they allow the use of any rail regardless of its section.

71

Previous Page

Previous Page